A kind of preparation technology of aluminum magnesium alginate

A technology of aluminum alginate and preparation process, which is applied in the field of preparation technology of aluminum magnesium alginate, can solve problems such as adverse reactions, unsatisfactory effects, etc., and achieves high reaction rate, enhanced barrier protection effect, and long duration of action. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

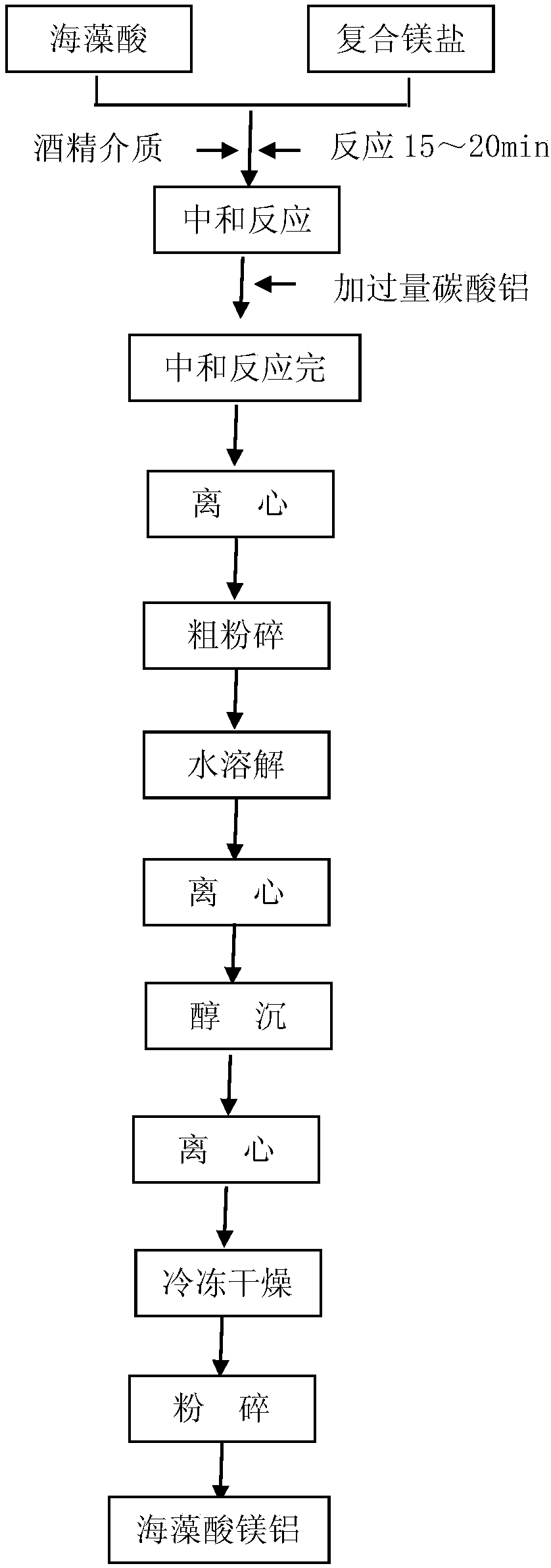

Method used

Image

Examples

Embodiment 1

[0021] Table 1

[0022] components

mass (kg)

44

magnesium hydroxide

1

20

[0023] Take each component according to table 1, and concrete production technology is as follows:

[0024] (1) Alginic acid and magnesium hydroxide are first placed in a neutralization tank containing 70% vol alcohol solution, and the neutralization reaction is carried out for 15 minutes;

[0025] (2) Add aluminum carbonate to the neutralization tank again, and continue the reaction until the alginic acid reacts completely;

[0026] (3) complete reaction centrifugation, after centrifugation for 40min, take out the centrifuged product and coarsely pulverize the coarse powder, place the pulverized floc in a water-filled neutralization tank, and stir until completely dissolved;

[0027] (4) After complete dissolution, centrifuge to remove water-insoluble matter, add 2-3 times of 95% ethanol to the aqueous solution, and stir ...

Embodiment 2

[0030] Table 2

[0031] components

mass (kg)

44

magnesium carbonate

3

12

[0032] Take each component according to table 2, and concrete production technology is as follows:

[0033] (1) First place alginic acid and magnesium hydroxide in a neutralization tank containing 71% vol alcohol solution, and carry out neutralization reaction for 17 minutes;

[0034] (2) Add aluminum carbonate to the neutralization tank again, and continue the reaction until the alginic acid reacts completely;

[0035] (3) complete reaction centrifugation, after centrifugation for 40min, take out the centrifuged product and coarsely pulverize the coarse powder, place the pulverized floc in a water-filled neutralization tank, and stir until completely dissolved;

[0036] (4) After complete dissolution, centrifuge to remove water-insoluble matter, add 2-3 times of 95% ethanol to the aqueous solution, and stir to precipitate...

Embodiment 3

[0039] table 3

[0040] components

mass (kg)

Alginic acid

44

magnesium hydroxide

1

magnesium carbonate

1

16

[0041] Take each component according to table 3, and concrete production technology is as follows:

[0042] (1) Alginic acid and magnesium hydroxide are first placed in a neutralization tank containing 72% vol alcohol solution, and the neutralization reaction is carried out for 20 minutes;

[0043] (2) Add aluminum carbonate to the neutralization tank again, and continue the reaction until the alginic acid reacts completely;

[0044] (3) complete reaction centrifugation, after centrifugation for 40min, take out the centrifuged product and coarsely pulverize the coarse powder, place the pulverized floc in a water-filled neutralization tank, and stir until completely dissolved;

[0045] (4) After complete dissolution, centrifuge to remove water-insoluble matter, add 2-3 times of 95% ethanol to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com