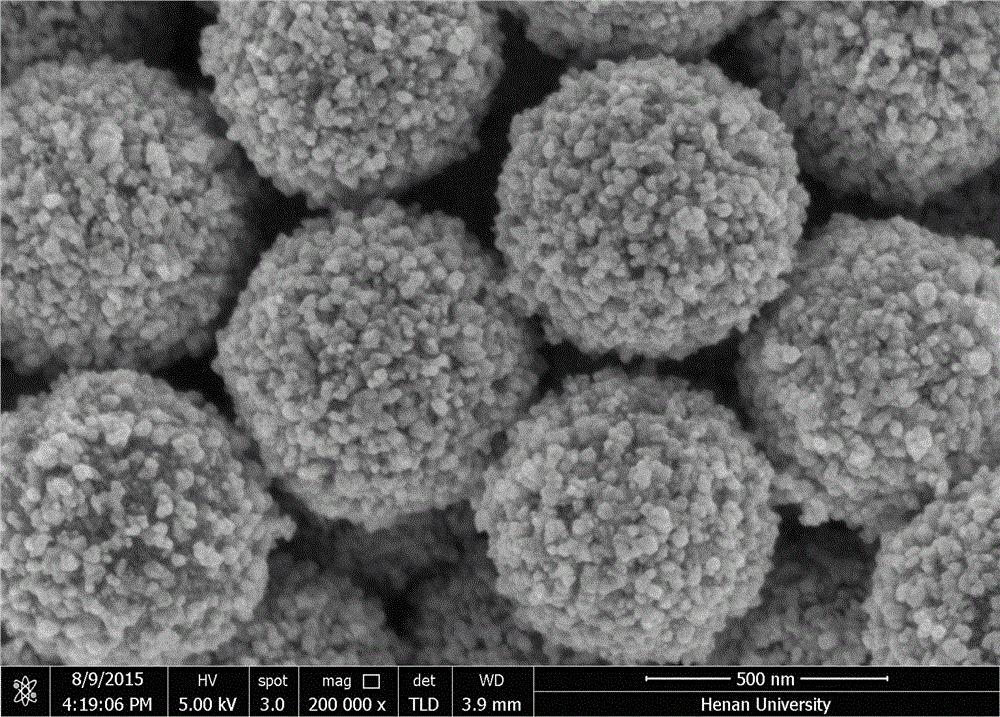

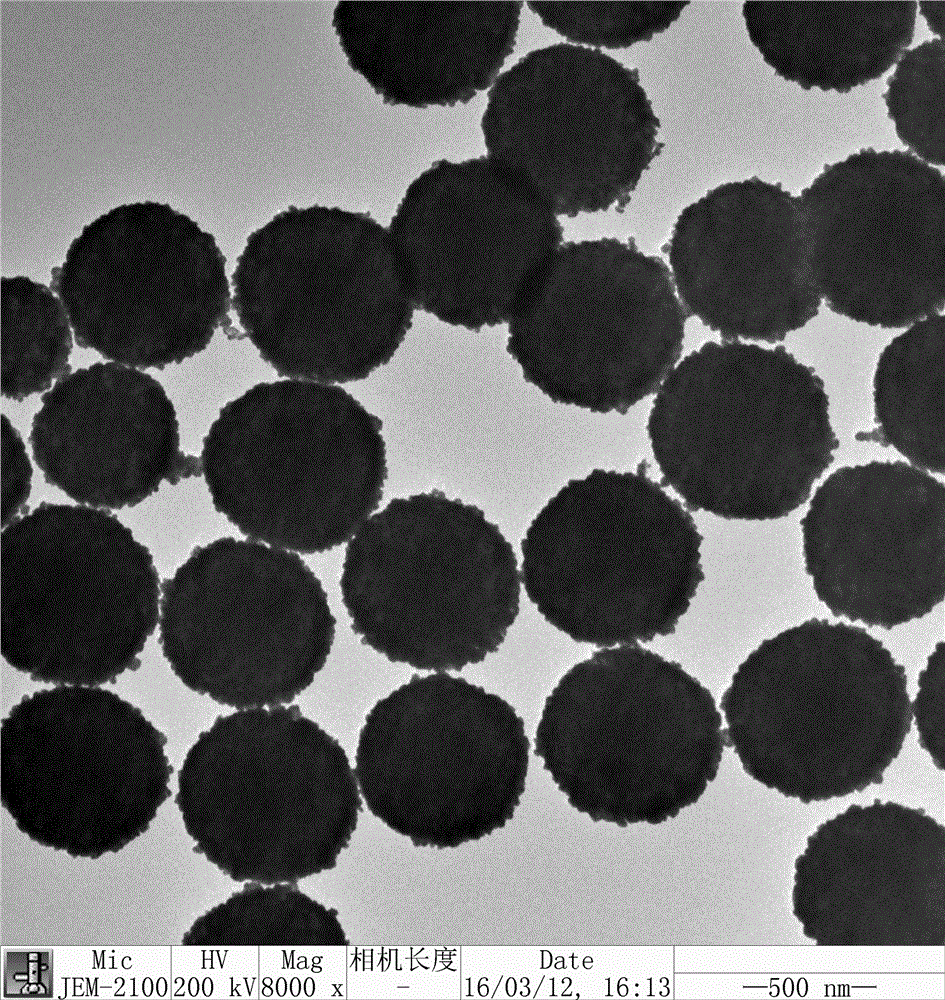

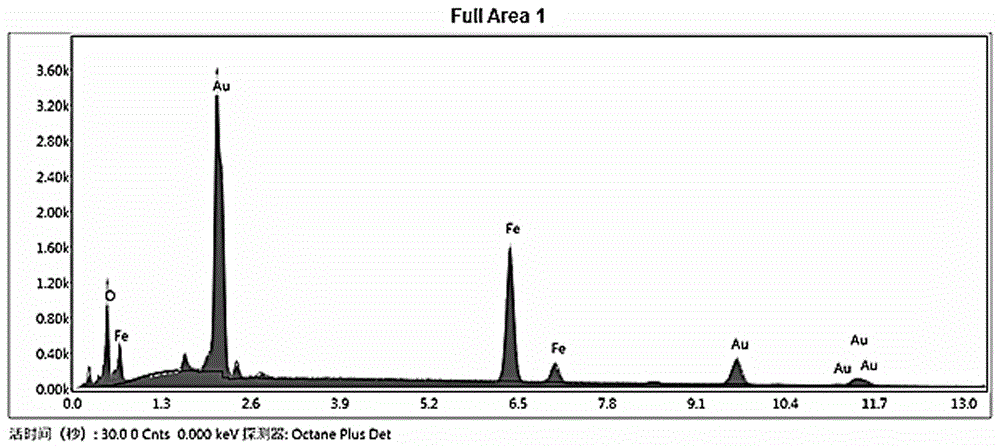

Preparation method and application of Fe3O4@PPy@Au magnetic composite microspheres

A technology of magnetic composite microspheres and magnetic nanoparticles, applied in the field of environmental analysis, to achieve the effect of simple process, easy access to raw materials, and high dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] a kind of Fe 3 o 4 The preparation method of PPyAu magnetic composite microspheres comprises the following steps: (1) 1gFe 3 o 4 Disperse magnetic nanoparticles in 85ml of distilled water, add 0.7g of polyvinylpyrrolidone, stir evenly with ultrasonic, then add 3ml of pyrrole and 35ml of absolute ethanol, stir evenly, add 5ml of hydrochloric acid (12mol / L) to react for 20min, wash with distilled water after magnetic separation , get Fe 3 o 4 PPy magnetic composite microspheres; (2) the Fe prepared in step (1) 3 o 4 PPy magnetic composite microspheres were added to 1450ml24mmol / L chloroauric acid solution, ultrasonically dispersed evenly, then magnetically separated, washed with distilled water, and dried at 60°C to obtain Fe coated with chloroauric acid 3 o 4 PPy magnetic composite microspheres; (3) Fe coated with chloroauric acid obtained in step (2) 3 o 4 PPy magnetic composite microspheres were dispersed in 15L of distilled water, and 3L of NaBH with a concen...

Embodiment 2

[0024] a kind of Fe 3 o 4 The preparation method of PPyAu magnetic composite microspheres comprises the following steps: (1) 1gFe 3 o 4 Disperse magnetic nanoparticles in 50ml of distilled water, add 0.429g of polyvinylpyrrolidone, stir evenly with ultrasonic, then add 2ml of pyrrole and 30ml of absolute ethanol, stir evenly, add 7ml of hydrochloric acid (10mol / L) to react for 15min, wash with distilled water after magnetic separation , get Fe 3 o 4 PPy magnetic composite microspheres; (2) the Fe prepared in step (1) 3 o 4 Add PPy magnetic composite microspheres to 3500ml20mmol / L chloroauric acid solution, ultrasonically disperse evenly, then wash with distilled water after magnetic separation, and dry at 55°C to obtain Fe coated with chloroauric acid 3 o 4 PPy magnetic composite microspheres; (3) Fe coated with chloroauric acid obtained in step (2) 3 o 4 PPy magnetic composite microspheres were dispersed in 10L of distilled water, and 2.5L of NaBH with a concentratio...

Embodiment 3

[0028] a kind of Fe 3 o 4 The preparation method of PPyAu magnetic composite microspheres comprises the following steps: (1) 1gFe 3 o 4 Disperse magnetic nanoparticles in 90ml of distilled water, add 1.428g of polyvinylpyrrolidone, stir evenly with ultrasonic, then add 4ml of pyrrole and 40ml of absolute ethanol, stir evenly, add 3ml of hydrochloric acid (12mol / L) to react for 25min, wash with distilled water after magnetic separation , get Fe 3 o 4 PPy magnetic composite microspheres; (2) the Fe prepared in step (1) 3 o 4 Add PPy magnetic composite microspheres to 2500ml30mmol / L chloroauric acid solution, ultrasonically disperse evenly, then wash with distilled water after magnetic separation, and dry at 65°C to obtain Fe coated with chloroauric acid 3 o 4 PPy magnetic composite microspheres; (3) Fe coated with chloroauric acid obtained in step (2) 3 o 4 PPy magnetic composite microspheres were dispersed in 20L of distilled water, and 4.5L of NaBH with a concentratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com