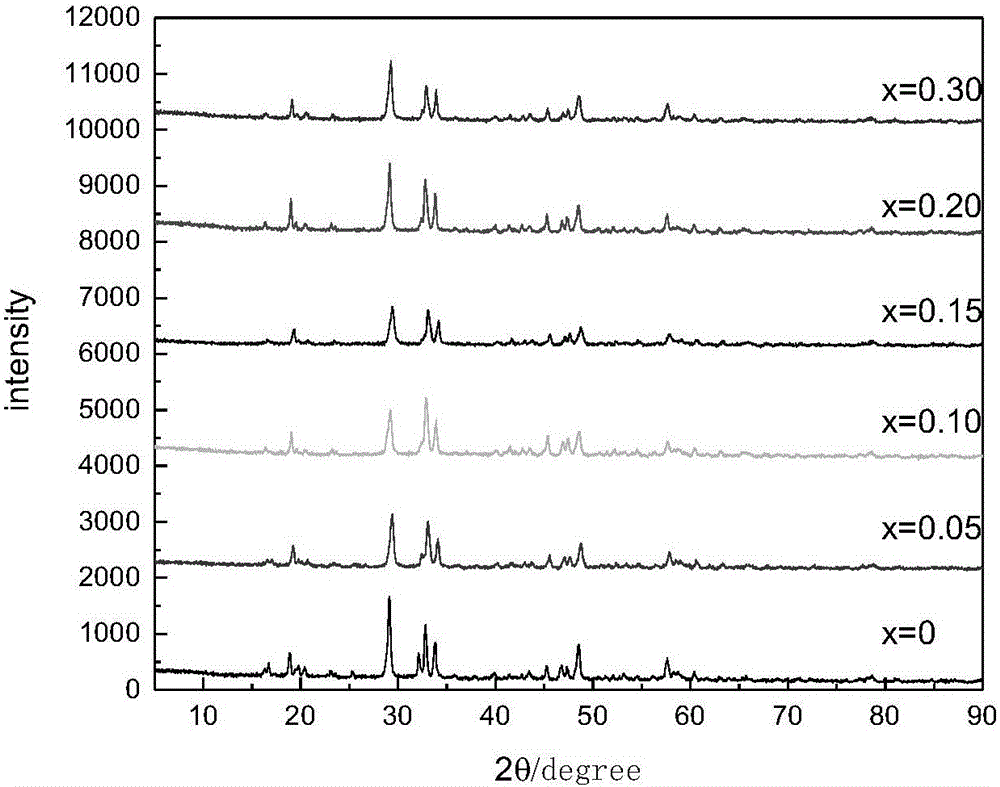

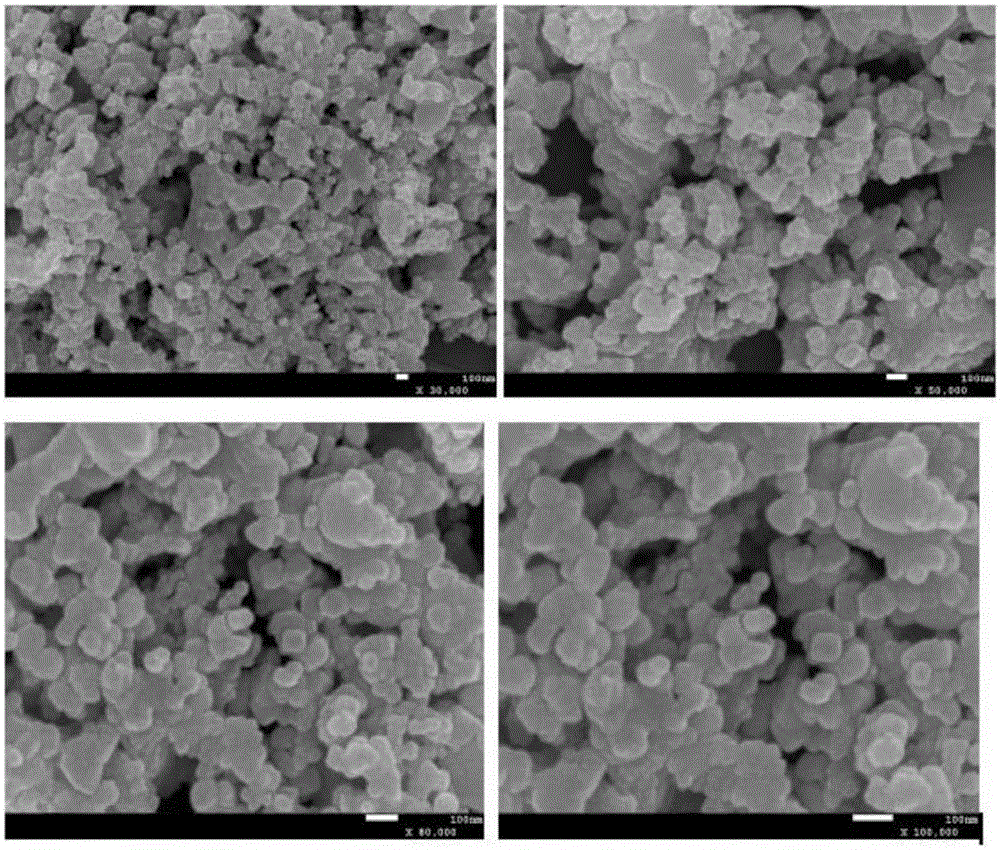

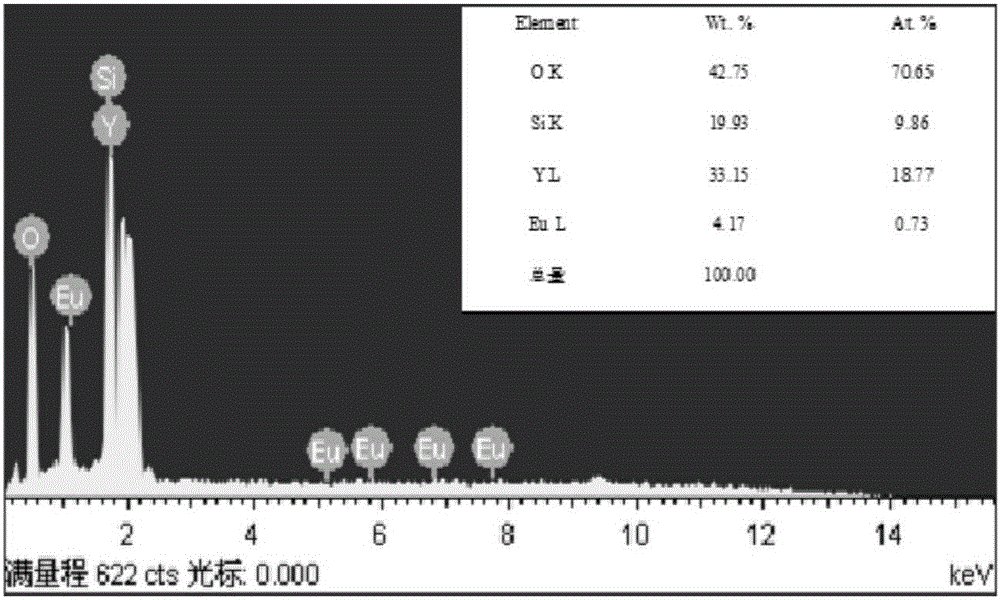

Monoclinic-system-structured superfine white nano fluorescent powder and preparation method thereof

A nano-phosphor, monoclinic technology, applied in the field of phosphors, can solve problems such as unfavorable industrial production, cumbersome operation steps, and difficulty in ensuring quality, and achieve bright colors, simple and controllable processes, and good thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] In addition, the preparation method of the ultrafine white nano phosphor powder with monoclinic crystal structure comprises the following steps:

[0034] (1) According to Y 2 Si 1-x Eu x o 5 The stoichiometric ratio of each element in , respectively take the corresponding Na2 SiO 3 ·5H 2 O, Eu(NO 3 ) 3 ·6H 2 O, Y (NO 3 ) 3 ·6H 2 O was dissolved in 100mL water to obtain a mixed solution;

[0035] (2) Add the mixed solution obtained in the above step (1) into the deionized aqueous solution of glycine dissolved in advance, keep the temperature at 60° C., and stir for at least 1 hour;

[0036] (3) Combust and condense the mixed solution of the above step (2) at 120°C, add a lubricant, the amount of the lubricant added is limited to be kept dispersed by the ball milling system, and then grind and dry to obtain the precursor powder;

[0037] (4) Put the precursor powder obtained in the above step (3) directly into a graphite crucible for calcination at a calcinati...

Embodiment 1

[0046] 0.22 g of europium nitrate, 7.66 g of yttrium nitrate and 2.70 g of sodium silicate were dissolved in 100 ml of water and stirred to obtain solution 1. Dissolve 3.08g of glycine into 50ml of water to obtain solution 2, pour solution 1 into solution 2, stir at 60°C until clear solution 3, and stir for 1.5 hours at a speed of 80 to 100 rpm by ultrasonic oscillation , and then concentrated and burned at 120°C to obtain the precursor powder. And the precursor powder was calcined at 800°C for 4 hours, the heating rate was 15°C / min, and then ground for 1 hour, and then followed the remaining specific steps in the above method to obtain the monoclinic structure Y 2 Si 0.9 Eu 0.1 o 5 Inorganic phosphors.

Embodiment 2

[0048] 0.45 g of europium nitrate, 7.66 g of yttrium nitrate and 2.56 g of sodium silicate were dissolved in 100 ml of water and stirred to obtain solution 1. Dissolve 3.15g of glycine into 50ml of water to obtain solution 2, pour solution 1 into solution 2, stir at 60°C until clear solution 3, and stir for 1.5 hours at a speed of 80 to 100 rpm by ultrasonic oscillation , and then concentrated and burned at 120°C to obtain the precursor powder. And the precursor powder was calcined at 800°C for 4 hours, the heating rate was 15°C / min, and then ground for 1 hour, and then followed the remaining specific steps in the above method to obtain the monoclinic structure Y 2 Si 0.9 Eu 0.1 o 5 Inorganic phosphors.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com