Method for preparing geothermal water corrosion preventing nano chemical composite plated layer

A technology of chemical composite plating and geothermal water, applied in liquid chemical plating, coating, metal material coating process, etc. Dispersion is difficult and other problems, to achieve the effect of improving corrosion resistance, good corrosion resistance, excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

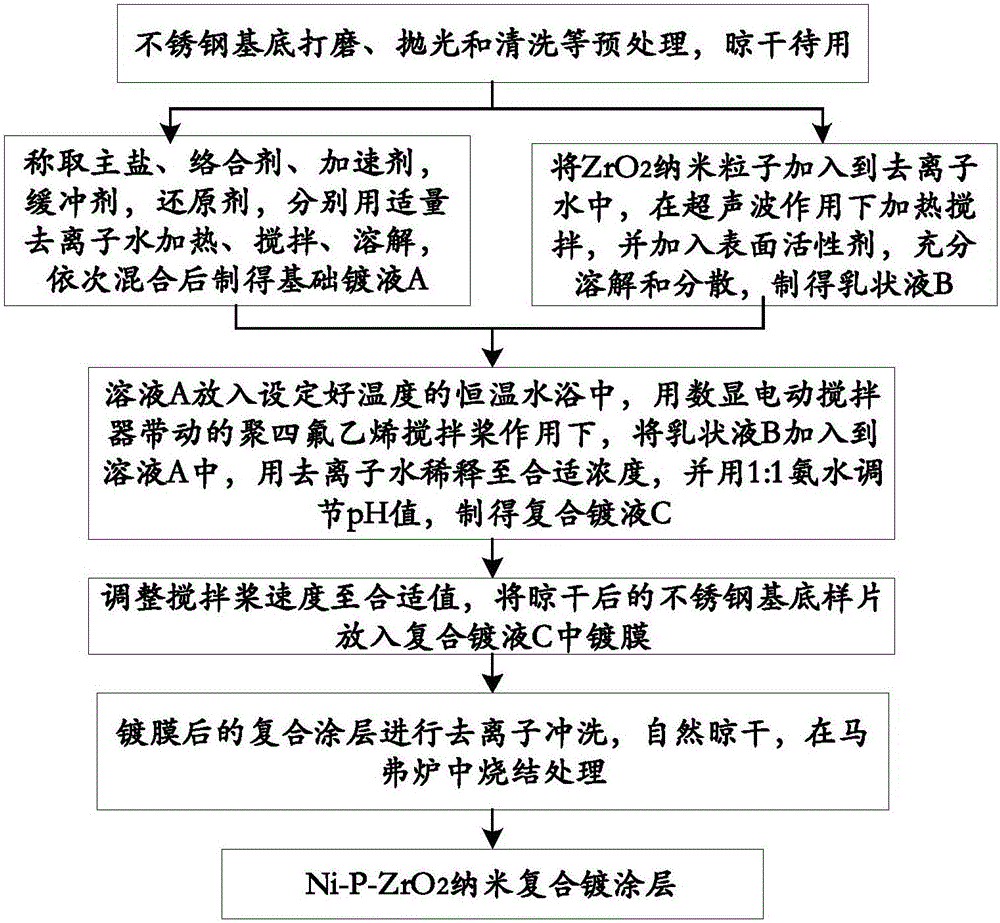

[0035] Such as figure 1 As shown, the anti-geothermal water corrosion nano chemical composite coating preparation method of the embodiment of the present invention comprises the following steps:

[0036] (1) Stainless steel substrate pretreatment process for coating preparation

[0037] The cut surface has a dense oxide film. Because the existence of these bumps and oxide films will lead to poor deposition of the coating on the surface of the substrate, it needs to be pretreated to make it meet the basic conditions of electroless plating. Substrate pretreatment mainly needs to go through processes such as grinding, polishing, washing with metal cleaners, washing with distilled water, and drying. The sample base needs to go through three steps:

[0038] ① Grinding: The purpose is to remove the oxide film on the surface of the substrate and the uneven scratches around it. First use a wheel grinder combined with a diamond wheel to remove the burrs after cutting, then use a 24...

Embodiment 1

[0050] (1) Substrate pretreatment

[0051]Stainless steel substrate pretreatment mainly needs to go through grinding, polishing, metal cleaning agent washing and distilled water cleaning, drying and other processes. The sample base needs to go through three steps: ① Grinding: first use a wheel grinder combined with a diamond wheel to remove the burrs after cutting, then use a 240-mesh louver to grind the base to remove obvious protrusions and grooves, and then use a nylon wheel to grind Remove the obvious scratches when the emery wheel is polished, and achieve the effect of surface flatness and cleanliness. ② Polishing: During the polishing process, the polished metal substrate surface is polished with a wool grinding wheel and a green polishing paste, and the polishing speed is 3000r / min. Then the substrate was naturally cooled to room temperature. ③ Washing: First use gauze and metal cleaning agent to clean the polished surface to remove a large amount of surface dirt. Th...

Embodiment 2

[0057] (1) Substrate pretreatment

[0058] Stainless steel substrate pretreatment mainly needs to go through grinding, polishing, metal cleaning agent washing and distilled water cleaning, drying and other processes. The sample base needs to go through three steps: ① Grinding: first use a wheel grinder combined with a diamond wheel to remove the burrs after cutting, then use a 240-mesh louver to grind the base to remove obvious protrusions and grooves, and then use a nylon wheel to grind Remove the obvious scratches when the emery wheel is polished, and achieve the effect of surface flatness and cleanliness. ② Polishing: During the polishing process, the polished metal substrate surface is polished with a wool grinding wheel and a green polishing paste, and the polishing speed is 3000r / min. Then the substrate was naturally cooled to room temperature. ③ Washing: First use gauze and metal cleaning agent to clean the polished surface to remove a large amount of surface dirt. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com