A high-voltage intensive thermoelectric refrigerator and its preparation method

A technology of thermoelectric refrigeration and thermoelectricity, which is applied to the operation mode of machines, machines using electric/magnetic effects, refrigerators, etc., can solve the problems of high power and unsuitability, and achieve improved stability and increased weldability Sexuality and the effect of improving cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] A high-voltage intensive thermoelectric refrigerator is characterized in that: the high-voltage intensive thermoelectric refrigerator consists of a gold-plated ceramic plate on the cold surface, a gold-plated ceramic plate on the hot surface, an N-type thermoelectric element, a P-type thermoelectric element, and The lead wire is composed of N-type thermoelectric element and P-type thermoelectric element in the middle, and gold-plated ceramic plates on both sides. The 3μm nickel layer is used as a welding transition layer and a heavy metal impurity barrier to protect the thermoelectric material from damage; the number of pairs of thermoelectric elements reaches 337 pairs, the effective area is 33mm*34mm, and the unit density is 0.2915 pairs / mm 2 , more than 0.1411 pairs / mm of conventional refrigerator 2 More than double the density; the pitch of thermoelectric elements is 0.5mm, which belongs to high-density thermoelectric components, which is much smaller than the pitch...

Embodiment 2

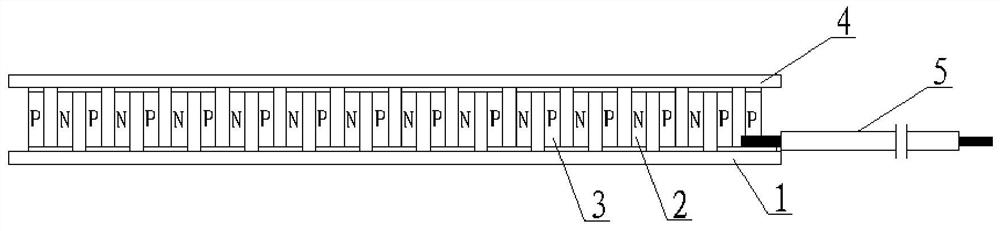

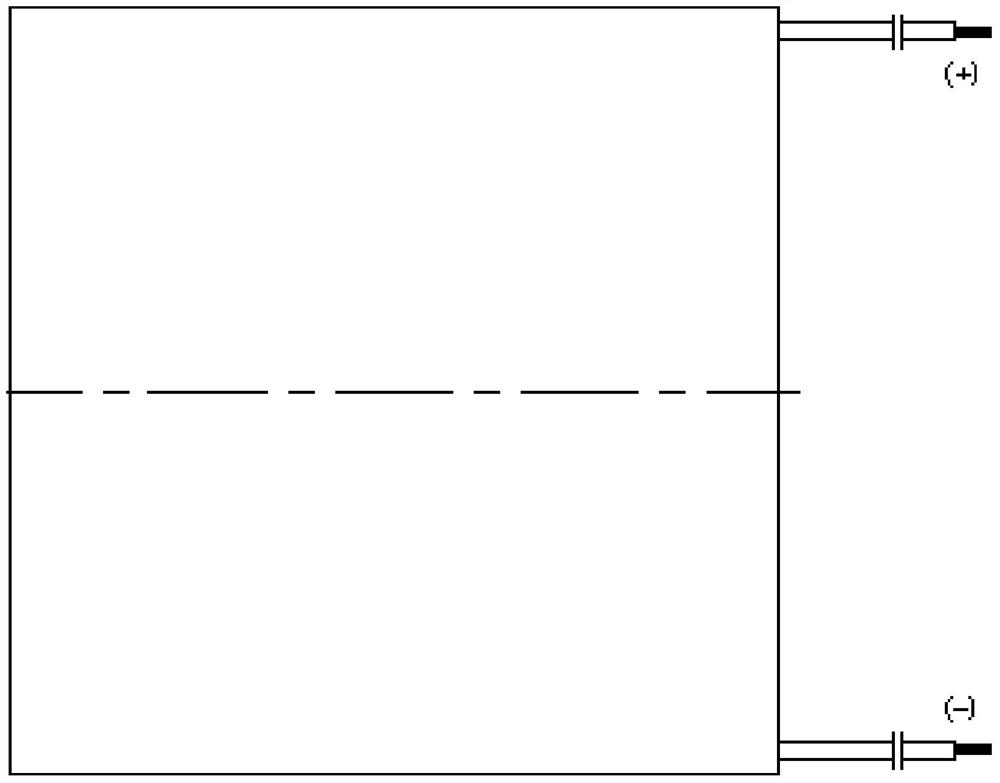

[0078] Refer to attached figure 1 with figure 2 .

[0079] A high-voltage intensive thermoelectric refrigerator is composed of gold-plated ceramic plates on the cold and hot surfaces, N and P-type thermoelectric elements, and solder through a welding process. It has a "sandwich" structure, that is, the thermoelectric element in the middle, and the two sides For gold-plated ceramic plates. The refrigerator with this structure has a low center of gravity and a flat structure, which is suitable for harsh mechanical environments. The base material of the gold-plated ceramic plate on the cold and hot surfaces is a ceramic sheet, which can be a 100% aluminum nitride ceramic substrate. The thickness of the aluminum and beryllium oxide ceramic substrate is 0.5mm; the surface of the ceramic substrate is sintered with 0.2mm thick red copper, the specification of the red copper is T2Y2, and the purity is >99.90%. The surface of the sintered copper clad laminate is polished to contro...

Embodiment 3

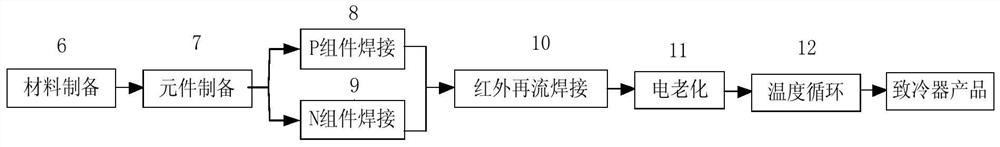

[0081] Refer to attached image 3 .

[0082] A preparation method of a high-voltage intensive thermoelectric refrigerator The preparation method is mainly material preparation → component preparation → P-type component welding → N-type component welding → infrared reflow welding → electrical aging → temperature cycle → refrigerator products . The material preparation method of the refrigerator mainly uses the regional smelting technology to prepare thermoelectric materials. The thermoelectric materials prepared by this method have good orientation characteristics and good thermoelectric transmission performance. The main path is raw material purification→thermoelectric material smelting→regional smelting→hot extrusion→annealing→thermoelectric performance testing. The main raw materials for the preparation of thermoelectric materials are Bi, Te, Se, Sb, etc. The requirement for such materials is that the purity is ≥99.99%. ", by introducing this technology to purify thermoel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com