Temperature fuse and organic temperature-sensing body thereof

A thermal fuse, an organic technology, applied in the field of fuses, can solve the problems of poor durability and continuity, low accuracy of melting temperature, aging and deterioration, etc., to achieve good durability and continuity, high operating temperature accuracy, and oxidation resistance strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The preparation of organic temperature sensing body 27:

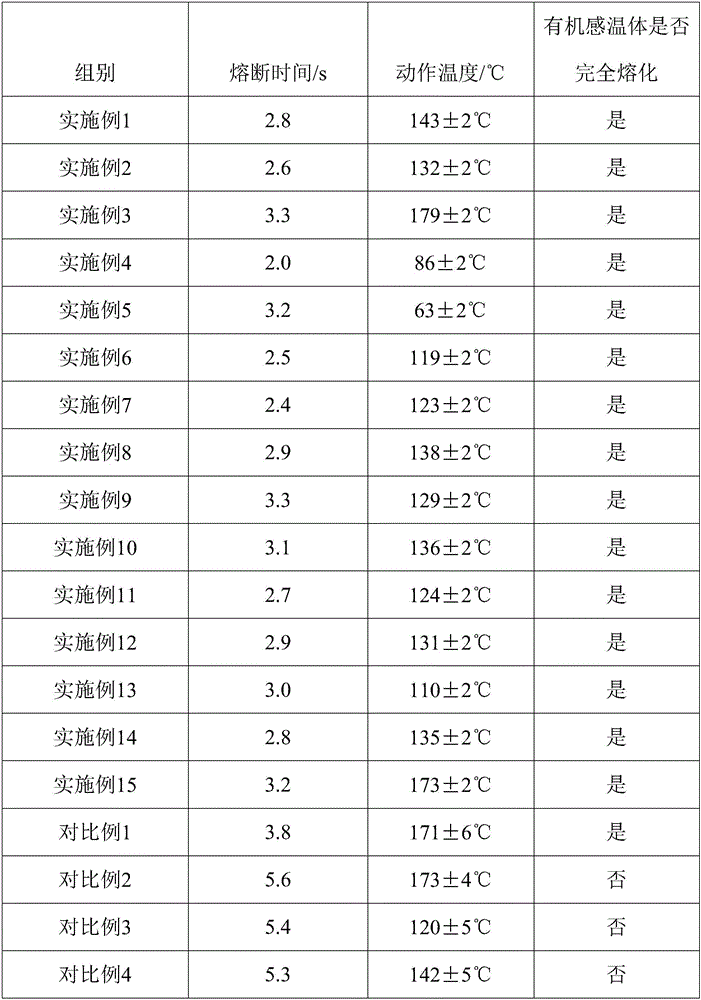

[0054] First mix 10% adipic acid, 60% succinic anhydride and 20% dimethyl terephthalate, heat to melt, then add 3% polyethylene, 5% ethanol and 2% poly The amide wax was stirred evenly, and then the organic temperature-sensitive body 27 of Example 1 was obtained through the steps of granulation, pressing and drying. The melting temperature analysis of the organic temperature-sensing body 27 shows that the melting temperature of the organic temperature-sensing body 27 is 142±2°C.

[0055] Preparation of thermal fuse:

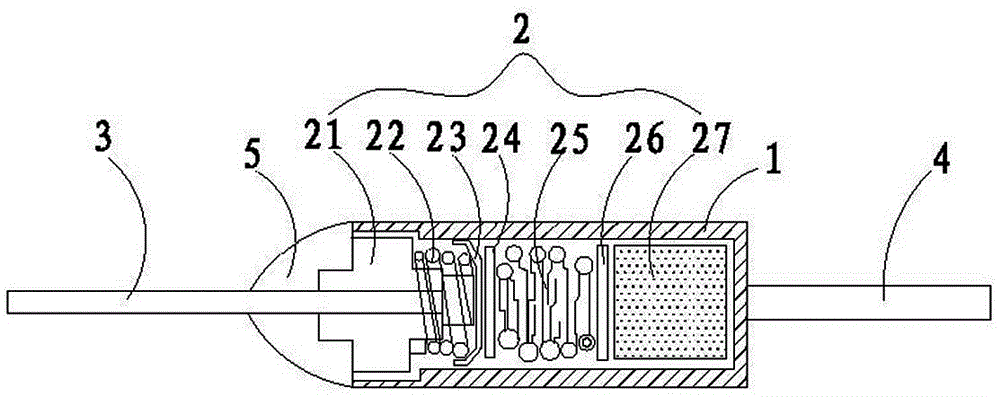

[0056]The thermal fuse includes a metal case 1 and a fuse 2 arranged inside the metal case 1, the metal case 1 is engraved with a product logo; one end of the metal case 1 is provided with a first pin 3, and the metal case 1 The other end is provided with a second pin 4, the first pin 3 is connected to the fuse 2 through a seal 5, and the material of the seal 5 is epoxy resin; the fuse 2 includes ...

Embodiment 2

[0059] Different from Example 1 is the preparation of organic temperature sensing body 27:

[0060] First mix 30% malonic acid, 40% succinic anhydride and 20% dimethyl terephthalate, heat to melt, then add 4% polypropylene, 5% ethanol and 1% hydrogenated Castor oil was stirred evenly, and then the organic temperature-sensitive body 27 of Example 2 was obtained through the steps of granulation, compression and drying. The melting temperature analysis of the organic temperature-sensing body 27 shows that the melting temperature of the organic temperature-sensing body 27 is 132±2°C.

[0061] The rest are the same as in Embodiment 1, and will not be repeated.

[0062] The operating temperature of the thermal fuse was tested to be 133±2°C, with an average value of 132.6°C.

Embodiment 3

[0064] Different from Example 1 is the preparation of organic temperature sensing body 27:

[0065] First mix 30% succinic acid, 40% succinic anhydride and 20% dimethyl terephthalate, heat to melt, then add 2% polystyrene, 6% methanol and 2% organic Stir the bentonite evenly, and then go through the steps of granulation, pressing and drying to obtain the organic temperature-sensitive body 27 of Example 3. The melting temperature analysis of the organic temperature-sensing body 27 shows that the melting temperature of the organic temperature-sensing body 27 is 178±2°C.

[0066] The rest are the same as in Embodiment 1, and will not be repeated.

[0067] The operating temperature of the thermal fuse was tested to be 179±2°C, with an average value of 178.8°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com