Method for real-time patterning of nitride growth silicon substrate

A patterning and nitride technology, applied in gaseous chemical plating, coating, electrical components, etc., can solve the problems of unsuitability for commercial application of silicon-based nitride semiconductor devices, increase manufacturing costs, and complex process, and reduce The effect of threading dislocation density, improving crystal quality, and reducing defect density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation of the method for real-time patterning of a silicon nitride growth substrate provided by the present invention will be described in detail below with reference to the accompanying drawings.

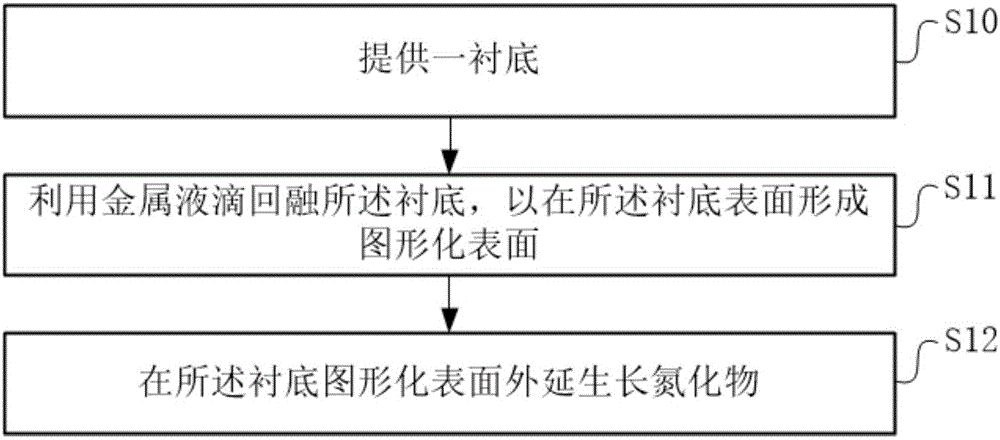

[0022] see figure 1 The method for real-time patterning of a silicon nitride growth substrate in the present invention includes the following steps: step S10, providing a substrate; step S11, using metal droplets to melt back the substrate to form a substrate on the surface of the substrate. Patterned surface; step S12 , epitaxially growing nitride on the patterned surface of the substrate.

[0023] Figure 2A ~ Figure 2D It is a process flow chart of the method for real-time patterning of a nitride growth silicon substrate according to the present invention.

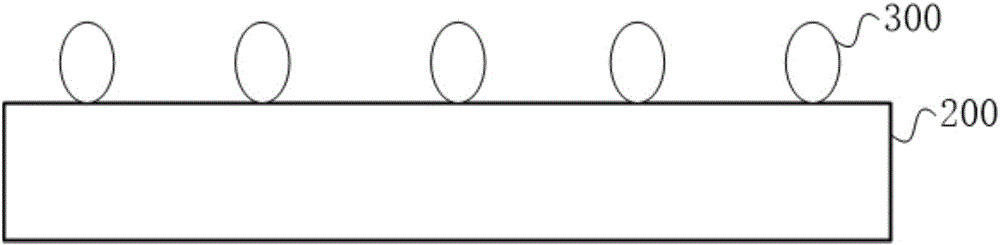

[0024] See step S10 and Figure 2A , providing a substrate 200 . The substrate 200 may be sapphire, silicon carbide, silicon, lithium aluminate, or gallium arsenide.

[0025] Refer to step S1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com