Method for preparing composite titanium dioxide powder with titanium-coated light calcium carbonate

A technology of light calcium carbonate and composite titanium dioxide, applied in chemical instruments and methods, dyeing polymer organic compound treatment, inorganic pigment treatment, etc., can solve the problems of weak bonding between particles, poor pigment performance and weather resistance, etc. Achieve strong weather resistance, enhanced lipophilicity, and high surface gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

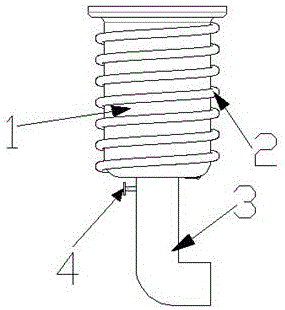

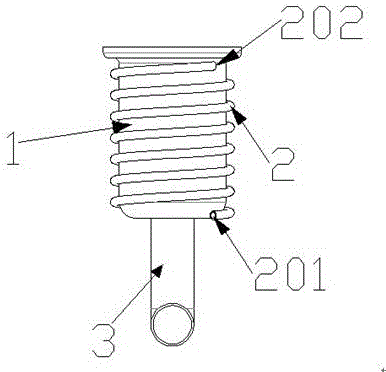

Image

Examples

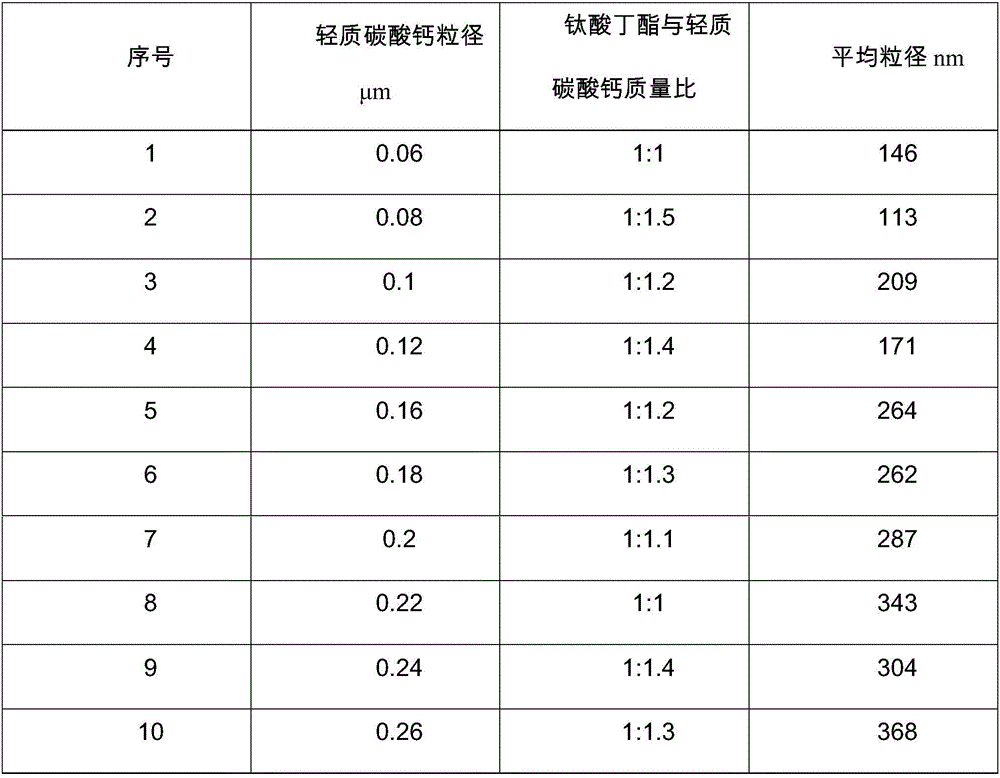

Embodiment 1

[0056] 1. Dissolve 340 g of butyl titanate in n-butanol solvent to prepare a butyl titanate solution with a concentration of 0.80 mol / L.

[0057] 2. Add 340 g of light calcium carbonate with a particle size of 0.1 μm to it, stir and disperse into a suspension.

[0058] 3. Add 156 mL of deionized water to it at a uniform speed within 40 minutes to hydrolyze the butyl titanate.

[0059] 4. After aging for 20 minutes, pass nitrogen gas for 4 minutes, add 20.4 g of methyl methacrylate, and stir for 10 minutes.

[0060] 5. Heat the system to 76°C at a heating rate of 4°C / min, add a small amount of BPO, and react for 50 minutes.

[0061] 6. After the reaction, cool down naturally, filter the slurry with a Buchner funnel, wash the filter cake with deionized water for 3 times, dry, and pulverize to obtain a composite titanium dioxide product.

[0062] 7. Carry out pigment performance testing, weather resistance testing and dispersion stability testing in the organic phase of the pro...

Embodiment 2

[0064] 1. Dissolve 340 g of butyl titanate in isobutanol solvent to prepare a butyl titanate solution with a concentration of 0.60 mol / L.

[0065] 2. Add 510 g of light calcium carbonate with a particle size of 0.2 μm to it, and ultrasonically disperse it into a suspension.

[0066] 3. Add 143 mL of deionized water to it at a uniform speed within 35 minutes to hydrolyze the butyl titanate.

[0067] 4. After aging for 16 minutes, pass nitrogen gas for 5 minutes, add 18 g of methyl methacrylate, and stir for 8 minutes.

[0068] 5. Heat the system to 80°C at a heating rate of 5°C / min, add a small amount of ammonium persulfate, and react for 40 minutes.

[0069] 6. After the reaction, cool down naturally, filter the slurry with a Buchner funnel, wash the filter cake 5 times with deionized water, dry it, and pulverize it to obtain a composite titanium dioxide product.

[0070] 7. Carry out pigment performance testing, weather resistance testing and dispersion stability testing in...

Embodiment 3

[0072] 1. Dissolve 340 g of butyl titanate in n-butanol solvent to prepare a butyl titanate solution with a concentration of 0.55 mol / L.

[0073] 2. Add 480 g of light calcium carbonate with a particle size of 0.18 μm to it, and ultrasonically disperse it into a suspension.

[0074] 3. Add 151 mL of deionized water to it at a uniform speed within 20 minutes to hydrolyze the butyl titanate.

[0075] 4. After aging for 10 minutes, inject nitrogen gas for 3 minutes, add 13.6 g of methyl methacrylate, and stir for 5 minutes.

[0076] 5. Heat the system to 72°C at a heating rate of 6°C / min, add a small amount of ammonium persulfate, and react for 60 minutes.

[0077] 6. After the reaction, cool down naturally, filter the slurry with a Buchner funnel, and wash the filter cake 4 times with deionized water, dry, and pulverize to obtain a composite titanium dioxide product.

[0078] 7. Carry out pigment performance testing, weather resistance testing and dispersion stability testing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com