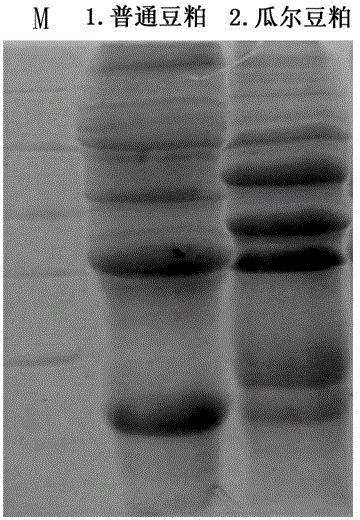

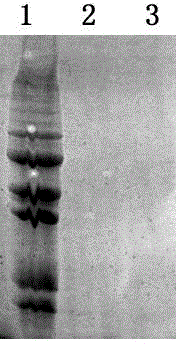

Preparation of new guar meal animal feed additive by mixed microbial solid fermentation

A feed additive, guar soybean meal technology, applied in the direction of animal feed, animal feed, application, etc., can solve the problems of affecting the utilization rate of protein and poor taste, and achieve the effect of improving the feeding value, improving the special smell and reducing the resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Step 1, raw material processing. Grind the guar soybean meal, take the quality of the soybean meal as a reference, add 35% water, stir and mix to moisten the material for 2 hours, keep the pH natural, sterilize at 115°C for 30 minutes, and cool for later use.

[0036] Step 2, preparation of composite strains.

[0037] (1) Activation of bacteria. Inoculate the strains from a slant or a glycerol tube into a triangular flask for activation. Bacillus subtilis and Bacillus licheniformis are cultured in nutrient broth medium, 37°C, 200rpm shake flask culture for 24 hours; Lactobacillus acidophilus, Lactobacillus lactis, lactic acid Streptococci were cultured in MRS broth medium and cultured at 37°C for 24 hours.

[0038](2) Primary seed preparation. Inoculate the activated bacterial liquid of Bacillus subtilis, Bacillus licheniformis, Lactobacillus acidophilus, Lactobacillus lactis and Streptococcus lactis into a 50L fermenter at an inoculum amount of 5% to prepare a first...

Embodiment 2

[0056] Animal experiments: Effects of fermented guar soybean meal on growth performance of piglets.

[0057] 1. Experimental design. 96 Du×Long×Large three-way hybrid piglets with similar parity and weight in good health at 30 days old (30±2 days old), similar in weight and in good health were selected as experimental animals, and divided into four treatment groups. There were 3 repetitions in each group, 8 animals in each repetition, and the test period was 30 days. The experiment adopted corn-soybean meal-fishmeal diet, the control group was fed the basal diet without guar meal, group A was fed the basal diet with 6% fermented guar meal, and group B was fed the basal diet with 8% fermented guar meal. The basal diet of guar soybean meal, group C was fed the basal diet with 10% fermented guar soybean meal. The basic diet is shown in Table 1. Feed according to the daily management mode of the pig farm, and the feeding site is regularly disinfected to ensure the feeding condi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com