Technology for catalytically treating VOCs by means of synergy between plasma and mesoporous

A plasma and catalytic treatment technology, which is applied in gas treatment, separation methods, and separation of dispersed particles, can solve the problems of energy consumption and by-product control, and affect industrial applications, etc., to prolong the time of synergistic degradation and effectively Conducive to the degradation of pollutants and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

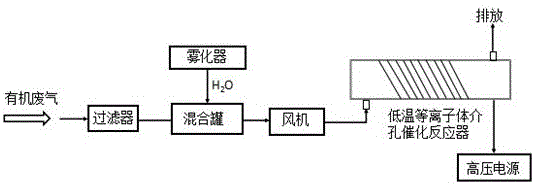

Method used

Image

Examples

Embodiment 1

[0032] Plasma synergistic mesoporous catalysis technology is used to degrade toluene-containing exhaust gas. The granular mesoporous catalyst is filled in the filled low-temperature plasma mesoporous catalytic reactor. The plasma discharge method is high-voltage pulse corona discharge, and the input voltage is 15kv, input frequency is 50Hz. The mesoporous catalyst is SBA-15 molecular sieve, and the surface is modified with 3% phenyl trioxyethyl silane, and then doped with 10% manganese oxide to modify the organic- Inorganic hybrid mesoporous catalyst. Intake mixed gas humidity is 5%, airspeed is 5000h -1 , The mixed gas to be treated enters the low-temperature plasma mesoporous catalytic reactor through a fan, and the synergistic effect of plasma oxidation capability, mesoporous catalyst adsorption and catalytic oxidation makes the removal rate of toluene reach 95.2% at room temperature.

Embodiment 2

[0034] Plasma synergistic mesoporous catalysis technology is used to degrade toluene-containing exhaust gas. The granular mesoporous catalyst is filled in the filled low-temperature plasma mesoporous catalytic reactor. The plasma discharge method is high-voltage pulse corona discharge, and the input voltage is 25kv, input frequency is 50Hz. The mesoporous catalyst is SBA-15 molecular sieve, and its surface is modified with phenyl trioxyethyl silane with a mass fraction of 7%, and then doped with manganese oxide with a mass fraction of 2% to modify the organic- Inorganic hybrid mesoporous catalyst. Intake mixed gas humidity is 20%, airspeed is 5000h -1 , The mixed gas to be treated enters the low-temperature plasma mesoporous catalytic reactor through a fan, and the synergistic effect of plasma oxidation capacity, mesoporous catalyst adsorption and catalytic oxidation makes the removal rate of toluene reach 93.7% at room temperature.

Embodiment 3

[0036] Plasma synergistic mesoporous catalysis technology is used to degrade toluene-containing exhaust gas. The granular mesoporous catalyst is filled in the filled low-temperature plasma mesoporous catalytic reactor. The plasma discharge method is high-voltage pulse corona discharge, and the input voltage is 20kv, input frequency is 500Hz. The mesoporous catalyst is SBA-15 molecular sieve, and its surface is modified with phenyl trioxyethyl silane with a mass fraction of 5%, and then doped with manganese oxide with a mass fraction of 6% to obtain organic- Inorganic hybrid mesoporous catalyst. Intake mixed gas humidity is 15%, airspeed is 5000h -1 , The mixed gas to be treated enters the low-temperature plasma mesoporous catalytic reactor through a fan, and the synergistic effect of plasma oxidation capacity, mesoporous catalyst adsorption and catalytic oxidation makes the removal rate of toluene reach 96.5% at room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com