Method of applying flue gas desulfurization ash modified material to wall whitewashing material

A technology of modified materials and desulfurization ash, which is applied in the direction of climate sustainability, solid waste management, sustainable waste treatment, etc., can solve the problems of not involving coatings, not really solving the problem of CaSO3 modification of desulfurization ash, and achieving saving Processing steps and the effect of speeding up construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

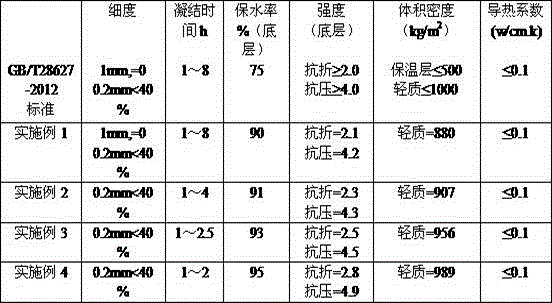

Examples

Embodiment 1

[0032] A method for applying flue gas desulfurization ash modified material to wall plastering materials. First, the flue gas desulfurization ash is modified so that calcium oxide in the flue gas desulfurization ash is converted into calcium hydroxide, and calcium sulfite is converted into sulfuric acid. Calcium, so as to obtain modified desulfurization ash; then use modified desulfurization ash as the main material, mix with alum powder, double fly powder and water retaining agent, after reconciliation treatment, get the stucco material applied to the wall. The proportion by weight of modified desulfurization ash, alum powder, double fly powder and water retaining agent is as follows:

[0033] Modified desulfurization ash 80-95%;

[0034]Alum powder 2-8%;

[0035] Shuangfei powder 0-15%;

[0036] Water retaining agent 0-5%.

[0037] The preparation method of the plastering material of the body of wall is:

[0038] 1. Convert the calcium oxide in the semi-dry desulfurizati...

Embodiment 2

[0041] A method for applying the flue gas desulfurization ash modified material to the wall plastering material. First, the flue gas desulfurization ash is modified so that the calcium oxide in the flue gas desulfurization ash is converted into calcium hydroxide, and the calcium sulfite is converted into sulfuric acid. Calcium, so as to obtain modified desulfurization ash; then use modified desulfurization ash as the main material, mix with alum powder, double fly powder and water retaining agent, after reconciliation treatment, get the stucco material applied to the wall. The proportion by weight of modified desulfurization ash, alum powder, double fly powder and water retaining agent is as follows:

[0042] Modified desulfurization ash 85-90%;

[0043] Alum powder 4-6%;

[0044] Shuangfei powder 0-8%;

[0045] Water retaining agent 2-3%.

[0046] The preparation method of the plastering material of the body of wall is:

[0047] 1. Convert the calcium oxide in the semi-dr...

Embodiment 3

[0050] A method for applying the flue gas desulfurization ash modified material to the wall plastering material. First, the flue gas desulfurization ash is modified so that the calcium oxide in the flue gas desulfurization ash is converted into calcium hydroxide, and the calcium sulfite is converted into sulfuric acid. Calcium, so as to obtain modified desulfurization ash; then use modified desulfurization ash as the main material, mix with alum powder, double fly powder and water retaining agent, after reconciliation treatment, get the stucco material applied to the wall. The proportion by weight of modified desulfurization ash, alum powder, double fly powder and water retaining agent is as follows:

[0051] Modified desulfurization ash 85%;

[0052] Alum powder 6%;

[0053] Shuangfei powder 5%;

[0054] Water retaining agent 4%.

[0055] The preparation method of the plastering material of the body of wall is:

[0056] 1. Convert the calcium oxide in the semi-dry desulfu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com