Guided tissue regeneration membrane and preparation method and application thereof

A technology for guiding tissue regeneration and biology, applied in the field of medical materials, can solve the problems of non-degradable regenerative membrane, poor plasticity of degradable membrane, easy collapse of tissue, etc., and is suitable for mass production, assisting bone growth and healing, preparation Simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

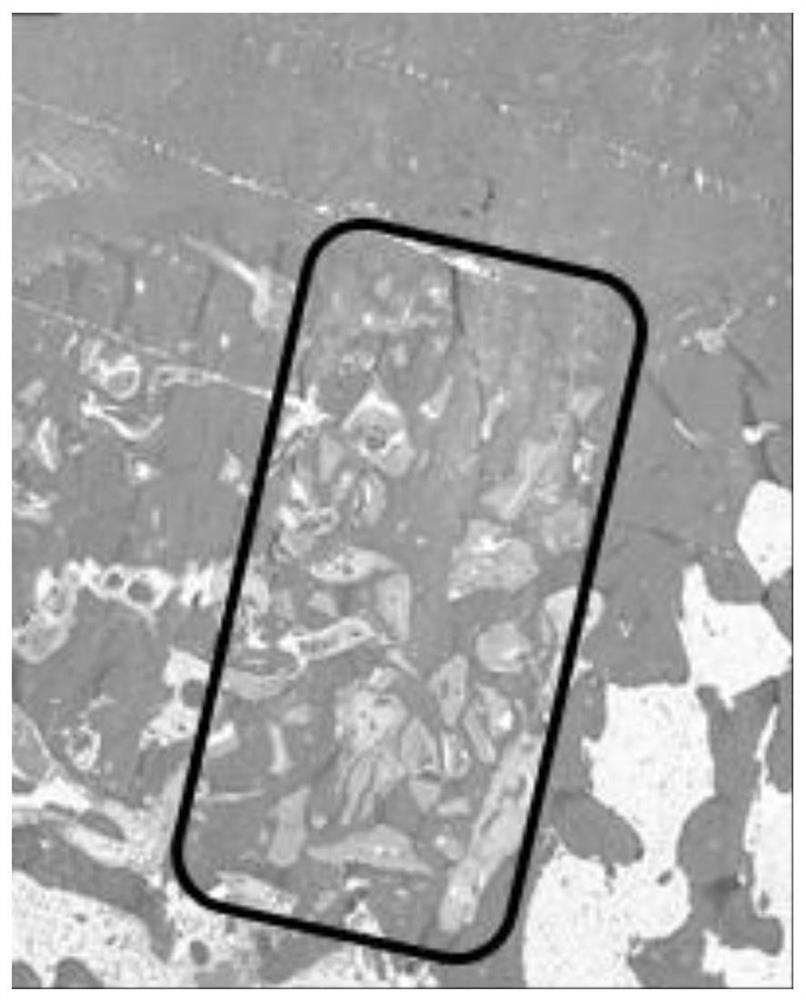

[0111] A second aspect of the present invention provides a method for preparing a guided tissue regeneration membrane according to the first aspect, comprising the step of compounding the fiber aggregate and the shaped body.

[0112] Typically, the preparation method comprises the following steps:

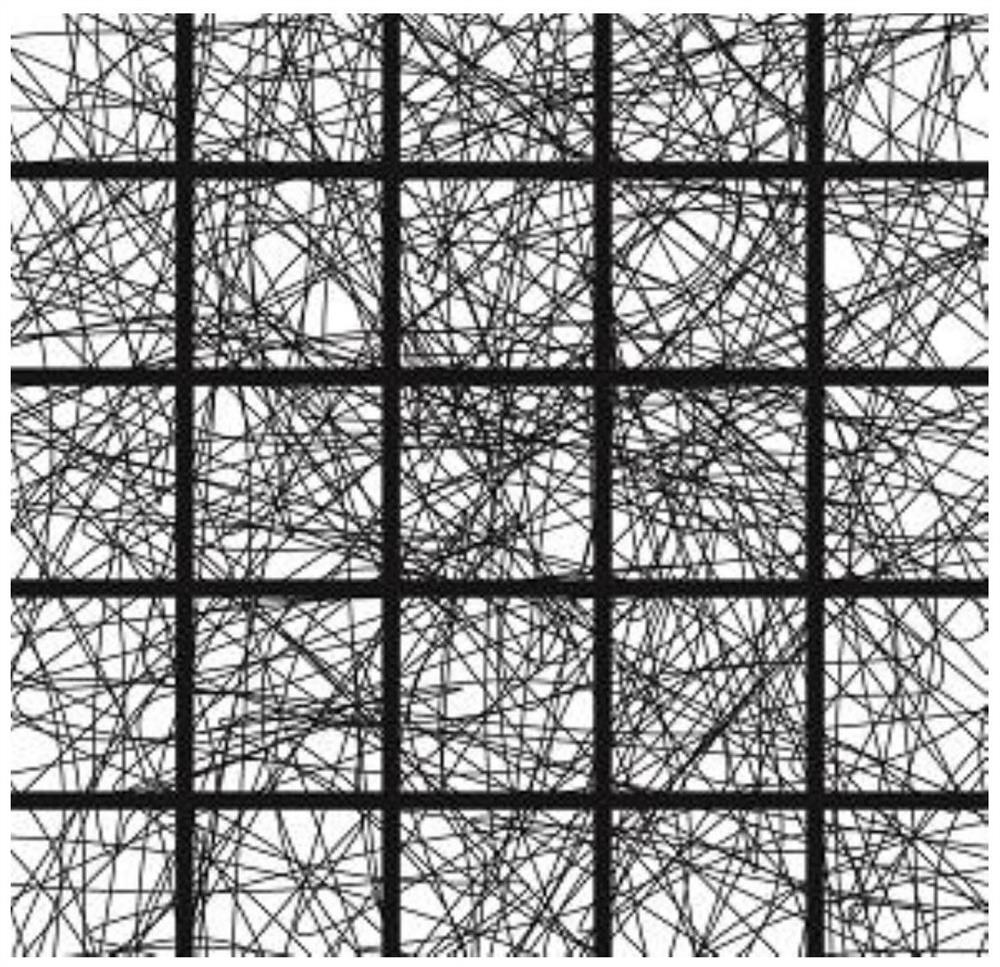

[0113] 3D printing process: prepare polymer material slurry, and use 3D printing technology to prepare the shaped body; in other specific embodiments, after mixing polymer material and osteogenic induction powder to form a printing slurry, use 3D printing technology The shaped body is prepared.

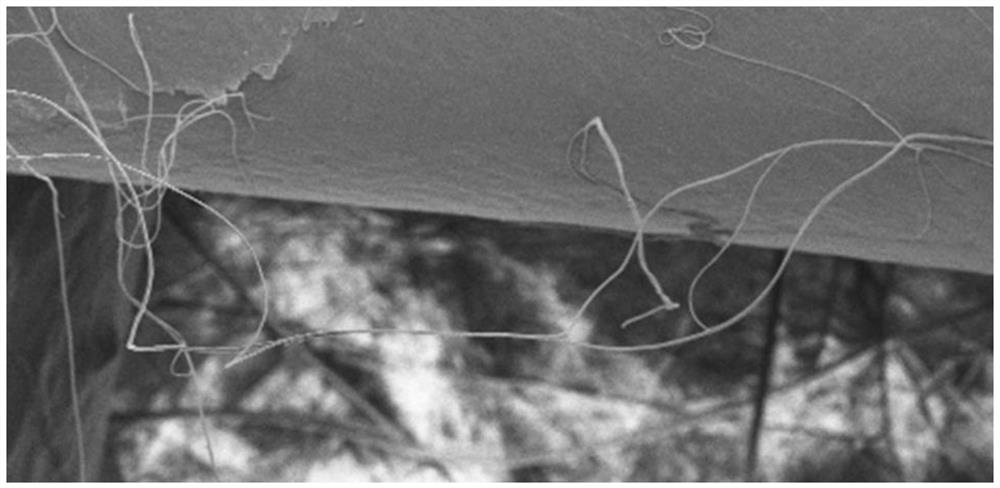

[0114] Electrospinning process: between the second fibers and / or on the surface of the second fibers, the fiber aggregate is prepared by electrospinning technology.

[0115] It is worth noting that the 3D printing process is carried out simultaneously with the electrospinning process.

[0116] In the present invention, the guided tissue regeneration membrane of the present invention is p...

Embodiment 1

[0146] The degradable polymer material poly(lactic-co-glycolic acid) (PLGA; LA / GA=50:50) particles were placed in the barrel of the printer.

[0147] The degradable polymer material polylactic acid was dissolved in the organic solvent chloroform to prepare a solution with a concentration (mass volume ratio) of 6%. In the bioglass solution, the content of calcium is 36 mole fractions, the content of silicon (ethyl orthosilicate) is 60 mole fractions, and the content of phosphorus (triethyl phosphate) is 8 mole fractions. The ester was hydrolyzed in hydrochloric acid with a pH value of 1.5. During hydrolysis, the molar ratio of silicon to deionized water was 1:8; after the hydrolysis was completed, triethyl phosphate was added to continue the hydrolysis, and after the hydrolysis was completed, calcium acetate was dissolved and allowed to stand for 6 hours. , to obtain the bioglass solution, ready for electrospinning.

[0148] The printing model is set as a square grid, the temp...

Embodiment 2

[0154] The degradable polymer material polycaprolactone (PCL) is prepared into powder by the method of freeze grinding, and the tricalcium phosphate powder with a particle size of 500nm-10μm is evenly mixed with the polycaprolactone powder, and placed in the printer. In the barrel, the mass ratio of polycaprolactone to tricalcium phosphate powder is 1:5.

[0155] The degradable polymer material polyglycolic acid (PGA) and hydrophilic factor gelatin are dissolved in the organic solvent trifluoroethanol according to the mass ratio of 3:1 to prepare a solution with a concentration (mass volume ratio) of 20% . In the bioactive glass solution, the content of calcium is 50 mole fractions, the content of silicon is 50 mole fractions, and the phosphorus content is 12 mole fractions. During hydrolysis, ethyl orthosilicate is hydrolyzed in hydrochloric acid with a pH value of 1.5. During hydrolysis, the molar ratio of silicon to deionized water is 1:10; after the hydrolysis is complete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com