Depressurization enhancement agent for water injection well and preparing method thereof

A technology of injection booster and carboxylic acid, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of difficult water injection, high injection pressure, and high energy consumption of the injection system, and achieve high injection pressure and preparation method Simple and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

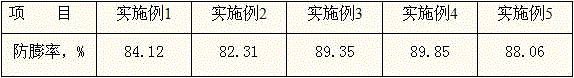

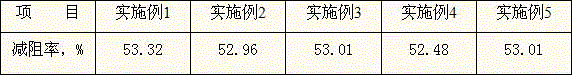

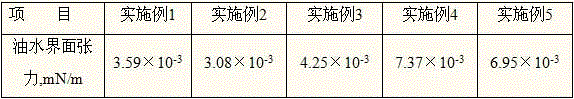

Examples

Embodiment 1

[0024] Add 545 kilograms of water, 100 kilograms of ethylene glycol monomethyl ether, 200 kilograms of octadecyl trimethylammonium chloride and 35 kilograms of polyoxyethylene in 1000 liters of stainless steel reaction kettles, start stirring, and reaction kettle is heated up to 50°C, stirred and reacted for 2 hours. After the solution is homogeneous, continue to add 100 kg of trimethylamine hydrochloride, 10 kg of polydimethyldiallyl ammonium chloride and 10 kg of trisodium nitrilotriacetate into the reaction kettle, and continue to stir and react for 1 hour to obtain Depressurization and injection booster products for water injection wells.

Embodiment 2

[0026] Add 555 kilograms of water, 100 kilograms of ethylene glycol monomethyl ether, 200 kilograms of octadecyl trimethylammonium chloride and 35 kilograms of polyoxyethylene in 1000 liters of stainless steel reaction kettles, start stirring, and reaction kettle is heated up to 60°C, stirred and reacted for 2 hours. After the solution is homogenized, continue to add 50 kg of trimethylamine hydrochloride, 50 kg of polydimethyldiallyl ammonium chloride and 10 kg of trisodium nitrilotriacetate into the reaction kettle, and continue to stir and react for 1.5 hours to obtain Depressurization and injection booster products for water injection wells.

Embodiment 3

[0028]Add 555 kg of water, 75 kg of ethylene glycol monomethyl ether, 100 kg of stearyl trimethyl ammonium chloride, and 100 kg of cetyl trimethyl ammonium propionate in a 1000-liter stainless steel reactor. kg and 35 kg of polyethylene oxide, start stirring, and the reaction kettle is heated to 45° C., and the reaction is stirred for 3 hours. After the solution is homogeneous, continue to add 50 kg of trimethylamine hydrochloride, 50 kg of ammonium chloride, 20 kg of polydimethyldiallyl ammonium chloride and 15 kg of trisodium nitrilotriacetate into the reactor, and continue to stir After 2 hours of reaction, the pressure-reducing and injection-increasing agent product for water injection wells was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Water phase permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com