Method for preparing high temperature-resistant lipase

A technology of lipase and high temperature resistance, applied in the field of fermentation, can solve the problems of complex process, low enzyme yield, poor temperature resistance of lipase, etc., and achieve the effect of wide pH range, expanded application field, and good tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

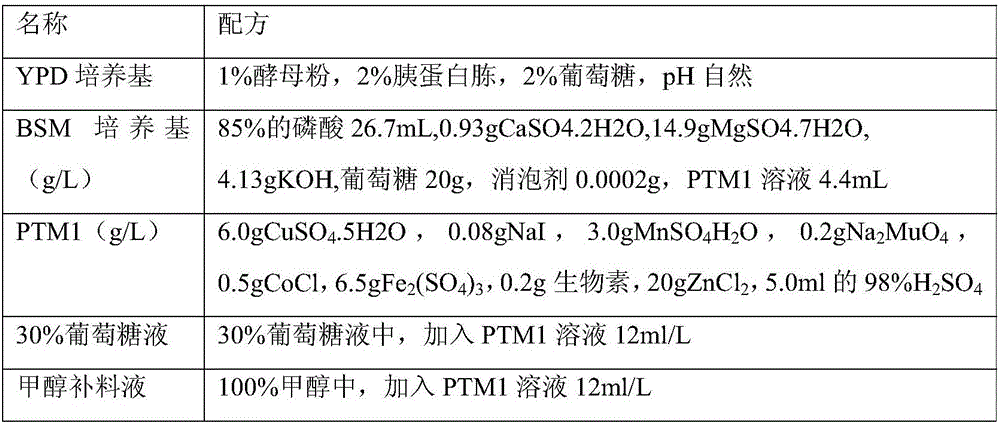

Method used

Image

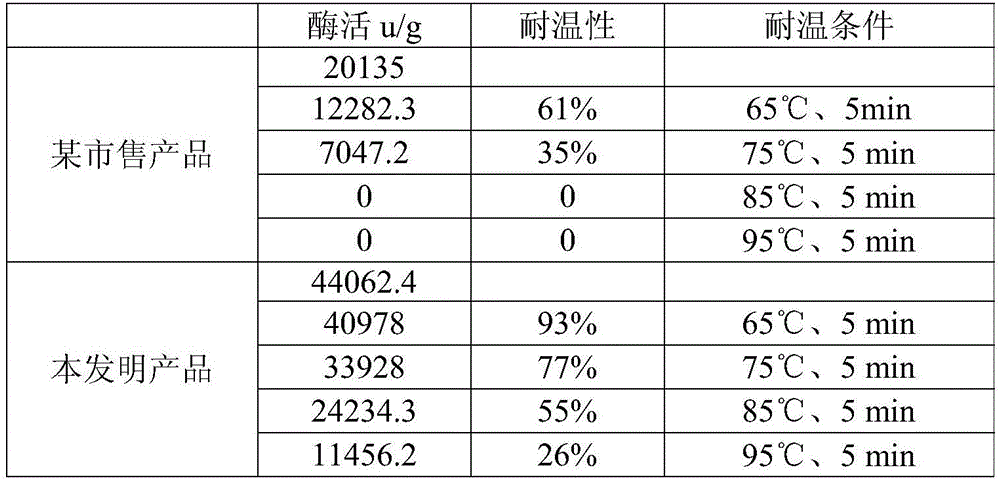

Examples

Embodiment 1

[0037] A preparation method of high temperature resistant lipase of the present invention, comprises the following steps:

[0038] (1) Gene cloning process: the high temperature resistant lipase gene derived from Bacillus subtilis is cloned into Pichia pastoris, and the cloning process is a conventional process;

[0039] (2) Seed preparation stage: the Pichia pastoris obtained after step (1) was cultured on a YPD slant medium to grow a single colony of Pichia pastoris, and then inoculated in a shake flask (100mL YPD medium in a 500mL shake flask) For cultivation, control the rotation speed of the shake flask at 220 rpm, and cultivate in a constant temperature shaker at 30° C. for about 26 hours to obtain shake flask seeds with a wet weight of 56 g / L.

[0040](3) First-level 200L seed tank cultivation: 100LYPD medium is placed in the seed tank, and the shaking flask seeds cultivated in step (1) are inoculated into the first-level seed tank with 2% inoculum, and the control stir...

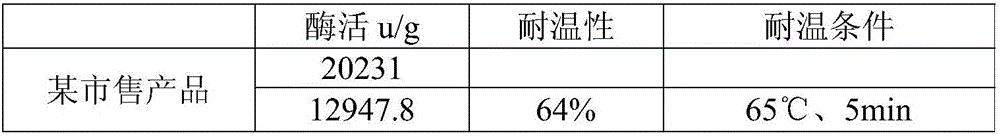

Embodiment 2

[0052] A preparation method of high temperature resistant lipase of the present invention, comprises the following steps:

[0053] (1) Gene cloning process: the high temperature resistant lipase gene derived from Bacillus subtilis is cloned into Pichia pastoris, and the cloning process is a conventional process;

[0054] (2) Seed preparation stage: the Pichia pastoris obtained after step (1) was cultured on a YPD slant medium to grow a single colony of Pichia pastoris, and then inoculated in a shake flask (100mL YPD medium in a 500mL shake flask) For cultivation, control the rotation speed of the shake flask at 200 rpm, and cultivate in a constant temperature shaker at 30° C. for about 31 hours to obtain shake flask seeds with a wet weight of 59 g / L.

[0055] (3) One-level 200L seed tank cultivation: 100LYPD medium is placed in the seed tank, and the shaking flask seeds cultivated in step (1) are inoculated into the first-level seed tank with 2% inoculum, and the control stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com