Preparation method of pH response type multi-scale structure polyvinylidene fluoride nanofiber membrane

A technology of polyvinylidene fluoride and nanofiber membranes, which is applied in non-woven fabrics, textiles and papermaking, etc., can solve the problems of polyvinylidene fluoride microfiltration membranes, structural limitations of liquid filtration accuracy and retention rate, etc., and achieve equipment Simple, convenient operation, process controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

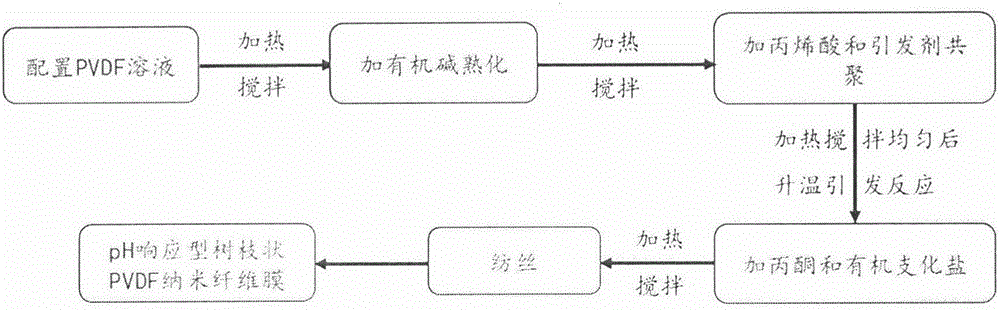

Method used

Image

Examples

Embodiment 1

[0024] (1) Configuration of PVdF solution: Take 1.2096g of PVdF powder, add 9mL of DMF, stir at 35°C to dissolve completely, and prepare a PVDF solution with a mass fraction of 10%;

[0025] (2) Solution aging: after the PVdF powder is completely dissolved, add 0.0968 g of polyethylene polyamine (PVdF powder mass 8%), heat in an oil bath at 40°C and stir for 24 hours;

[0026] (3) Graft copolymerization with acrylic acid: Add 0.2419g acrylic acid (20% of the mass of PVdF powder) and 0.0242g potassium persulfate (2% of the mass of PVdF powder) to the spinning solution in the previous step, heat up to 50°C, dissolve After reaching uniformity, the temperature was raised to 70°C to initiate the reaction for h;

[0027] (4) Electrospinning: after the reaction in the previous step, cool down to 30°C, add 2.25mL of acetone (1 / 4 of the volume of DMF), 0.0605g of tetrabutylammonium bromide (5% of the PVdF powder mass), After being fully dissolved, the electrospinning method was used for...

Embodiment 2

[0029] (1) with embodiment 1;

[0030] (2) Solution maturing: After the PVdF powder is completely dissolved, add 0.1310 g of polyethylene polyamine (PVdF powder mass 10%), heat in an oil bath at 50°C and stir for 24 hours;

[0031] (3) Graft copolymerization with acrylic acid: Add 0.1310g acrylic acid (10% of PVdF powder mass) and 0.036g potassium persulfate (3% of PVdF powder mass) to the spinning solution in the previous step, heat up to 55°C, dissolve After reaching uniformity, the temperature was raised to 75°C to initiate the reaction for 3 hours;

[0032] (4) Electrospinning: After the reaction in the previous step, cool down to 40°C, add 3mL of acetone (1 / 3 of the volume of DMF), and 0.1310g of tetrabutylammonium bromide (10% of the mass of PVdF powder), and wait After fully dissolved, the electrospinning method was used for spinning, the spinning voltage was 35kV, the receiving distance was 20cm, and the liquid supply rate was 0.5ml / h, and the pH-responsive multi-scal...

Embodiment 3

[0034] (1) Configuration of PVdF solution: Take 2.073g of PVdF powder, add 9mL of DMF, stir at 40°C to dissolve completely, and prepare a PVDF solution with a mass fraction of 16%;

[0035] (2) Solution aging: after the PVdF powder is completely dissolved, add 0.2073g polyethylene polyamine (10% of the PVdF powder mass) to the solution, heat in an oil bath at 55°C and stir for 24h;

[0036] (3) Graft copolymerization with acrylic acid: add 0.2073g of acrylic acid (10% of the PVdF powder mass) and 0.0622g of potassium persulfate (3% of the PVdF powder mass) to the spinning solution of the previous step, and heat up to 55°C , dissolve until uniform and then raise the temperature to 75°C to initiate the reaction for 3h;

[0037] (4) Electrospinning: After the reaction in the previous step, cool down to 40°C, add 3mL of acetone (1 / 3 of the volume of DMF), and 0.3110g of tetrabutylammonium bromide (15% of the mass of PVdF powder). After fully dissolved, the electrospinning method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com