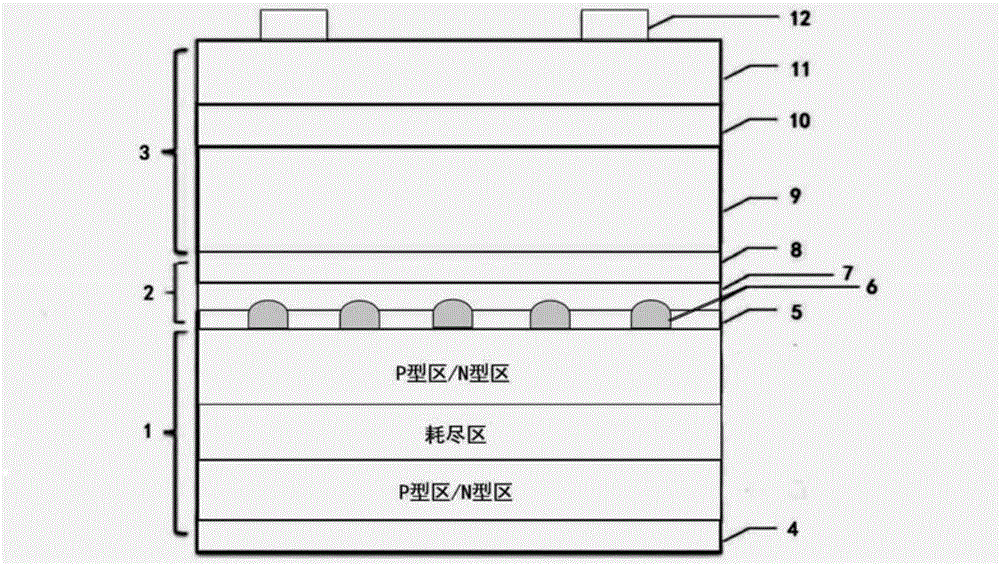

Antimony sulfide/silicon tandem solar cell and preparation method thereof

A technology of stacking solar and antimony sulfide, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problem of no research reports on antimony sulfide/silicon stacked solar cells, and achieve the goal of reducing capital investment, saving resources, and accelerating promotion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

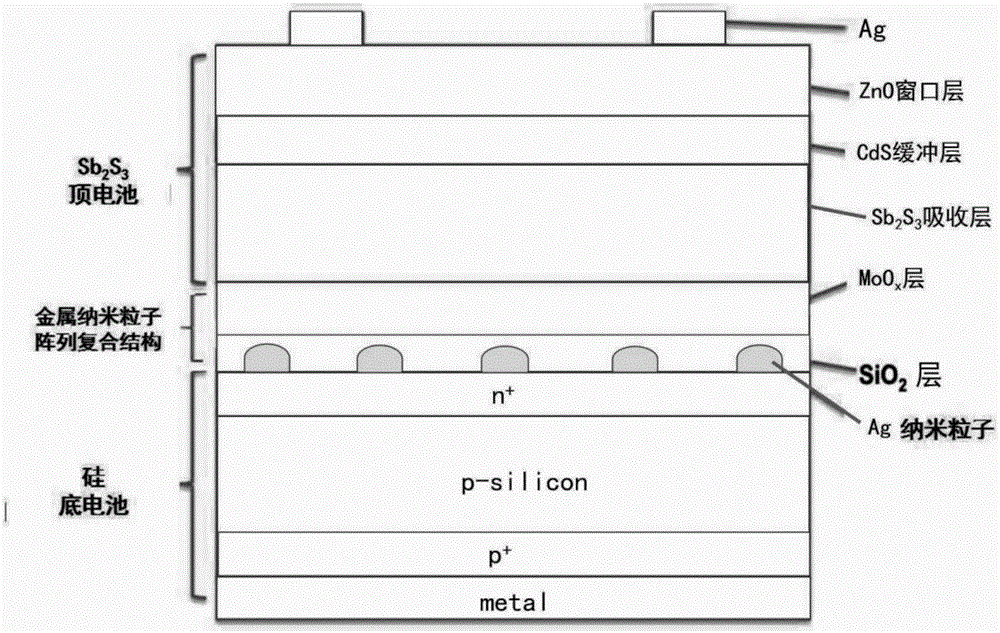

Embodiment 1

[0049] The upper surface of the crystalline silicon cell that has not undergone texturing, passivation and metallization is routinely cleaned, and an Ag metal layer is prepared on the surface by magnetron sputtering. Using Ag as the target material, DC sputtering is adopted, the sputtering power is 80w, the air pressure is 0.5Pa, the substrate temperature is normal temperature, the distance between the target and the substrate is 10cm, and the sputtering time is 8min to form an Ag metal layer with a thickness of about 100nm.

[0050] Thermal annealing is performed on the Ag metal layer, and annealed at 500° C. for 40 minutes in an argon atmosphere to form a metal nanoparticle array.

[0051] Anneal at 100°C for 10 minutes in an air atmosphere to oxidize the upper surface of the crystalline silicon cell to form SiO 2 layer.

[0052] Metal nanoparticles and SiO by thermal evaporation 2 Preparation of MoO on the surface of the composite layer x layer, using Mo metal as the eva...

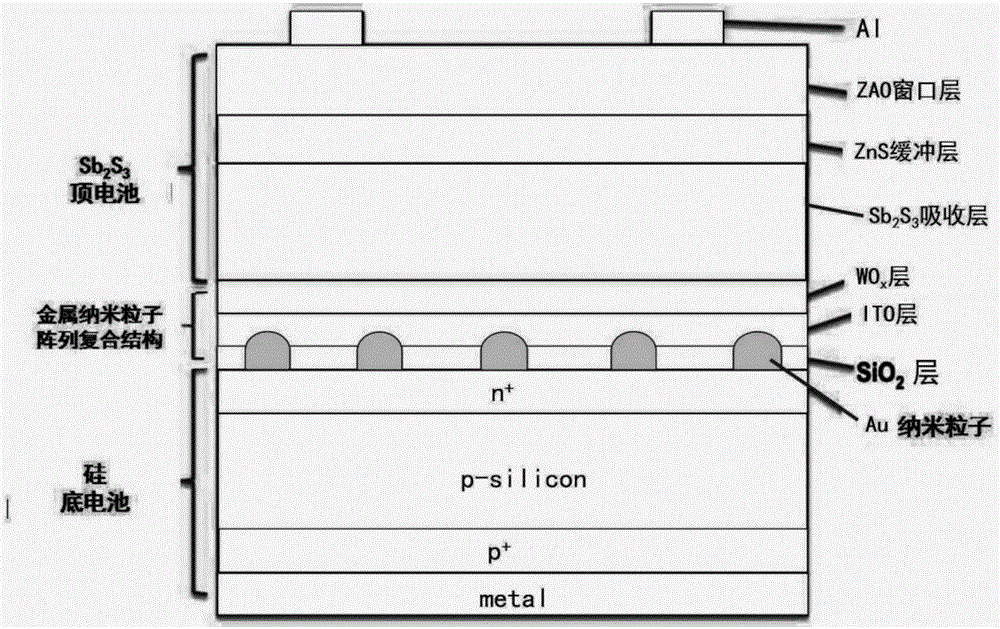

Embodiment 2

[0060] On the upper surface of the crystalline silicon cell that has not undergone texturing, passivation and metallization, an Au metal layer is prepared by vacuum evaporation. Using Au as the evaporation source, the air pressure is 0.001Pa, the evaporation source temperature is 800°C, and the evaporation time is 40min to form an Au metal layer with a thickness of about 30nm.

[0061] The Au metal layer is thermally annealed at 850° C. for 20 minutes in an argon atmosphere of 0.001 Pa to form an array of Au nanoparticles.

[0062] The ITO layer was prepared by magnetron sputtering, the substrate temperature was normal temperature, the sputtering power was 60w, the air pressure was 0.4Pa, and the sputtering time was 10min to form an ITO layer with a thickness of about 300nm.

[0063] Thermal annealing of the ITO layer makes it react with the surface of the silicon cell to form SiO 2 layer, the annealing temperature is 300°C, and the annealing time is 100min.

[0064] Prepara...

Embodiment 3

[0072] A Pd metal layer was prepared by magnetron sputtering on the upper surface of the crystalline silicon cell without texturing, passivation and metallization. Using Pd as the target material, DC sputtering is adopted, the sputtering power is 60w, the air pressure is 1.5Pa, the substrate temperature is normal temperature, the distance between the target and the substrate is 10cm, and the sputtering time is 15min to form a Pt metal layer with a thickness of about 150nm.

[0073] Thermally anneal the Pd metal layer at 300°C, 5×10 -4 Annealed in Pa argon atmosphere for 80min to form Pd nanoparticle array.

[0074] The FTO layer was prepared by magnetron sputtering. The substrate temperature is room temperature, the sputtering power is 80w, the air pressure is 1Pa, and the sputtering time is 15min, to form an FTO layer with a thickness of 800nm.

[0075] Thermally anneal the FTO layer to make it react with the surface of the silicon cell to form SiO 2 layer, the annealing t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com