Anti-cracking exterior wall putty and preparation method thereof

An external wall putty and anti-cracking technology, applied in the direction of filling slurry, etc., can solve the problems of unstable chemical properties, low bonding strength, poor water resistance, etc., and achieve superior bonding strength, good cracking resistance, and gloss good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

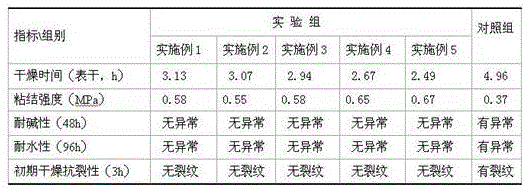

Examples

Embodiment 1

[0044] Example 1 A crack-resistant exterior wall putty prepared from the following raw materials (23 kg per part): 15 parts of calcium carbonate, 11 parts of polyvinylidene chloride, 10 parts of microcrystalline cellulose, 13 parts of polyvinyl alcohol 13 parts of attapulgite, 10 parts of soluble starch, 95 parts of heavy calcium carbonate, 28 parts of high calcium fly ash, 2.8 parts of emulsified silicone oil, 3.5 parts of sodium carboxymethyl cellulose, 1.6 parts of benzoic acid, lignocellulose 3.6 parts, 2.5 parts of casein.

[0045] The preparation steps of a crack-resistant exterior wall putty are as follows:

[0046] (1) Crush the polyvinyl alcohol, put it in the reaction tank, add 3 times the mass of water, add high-calcium fly ash after standing for 2 hours, heat to 56°C, keep warm for 2 hours, stir evenly, filter, and cool to Room temperature, dry, grind, pass through 80 mesh sieve;

[0047] (2) Put the attapulgite and heavy calcium carbonate in a pulverizer, mechan...

Embodiment 2

[0052] Example 2 A crack-resistant exterior wall putty prepared from the following raw materials (14 kg per part): 20 parts of calcium carbonate, 16 parts of polyvinylidene chloride, 16 parts of microcrystalline cellulose, and 17 parts of polyvinyl alcohol 18 parts of attapulgite, 20 parts of soluble starch, 105 parts of heavy calcium carbonate, 36 parts of high calcium fly ash, 3.6 parts of emulsified silicone oil, 4.2 parts of sodium carboxymethyl cellulose, 2.2 parts of benzoic acid, lignocellulose 4.3 parts, 3.2 parts of casein.

[0053] The preparation steps of a crack-resistant exterior wall putty are as follows:

[0054] (1) Crush the polyvinyl alcohol, put it in the reaction tank, add 5 times the mass of water, add high-calcium fly ash after standing for 3 hours, heat to 62°C, keep it warm for 4 hours, stir evenly, filter, and cool to Dry at room temperature, grind, pass through a 120-mesh sieve, and set aside;

[0055] (2) Put the attapulgite and heavy calcium carbo...

Embodiment 3

[0060] Example 3 A crack-resistant exterior wall putty prepared from the following raw materials (15 kg per part): 17 parts of calcium carbonate, 12 parts of polyvinylidene chloride, 12 parts of microcrystalline cellulose, and 14 parts of polyvinyl alcohol 15 parts of attapulgite, 13 parts of soluble starch, 98 parts of heavy calcium carbonate, 30 parts of high calcium fly ash, 3.0 parts of emulsified silicone oil, 3.8 parts of sodium carboxymethyl cellulose, 1.8 parts of benzoic acid, lignocellulose 3.8 parts, 2.7 parts of casein.

[0061] The preparation steps of a crack-resistant exterior wall putty are as follows:

[0062] (1) Crush the polyvinyl alcohol, put it in the reaction tank, add 3.5 times the mass of water, add high-calcium fly ash after standing for 2.3 hours, heat to 58 ° C, keep warm for 2.5 hours, stir evenly, filter, and cool to At room temperature, dry, grind, pass through a 90-mesh sieve, and set aside;

[0063] (2) Put the attapulgite and heavy calcium c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com