Anti-aging flame-retardant power cable

A power cable, aging-resistant technology, applied in power cables, insulated cables, cables, etc., can solve the problems of life-threatening safety, poor aging resistance, low mechanical properties, etc., to broaden the scope of application, excellent resistance to overheating Water properties, the effect of increasing the crosslinking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

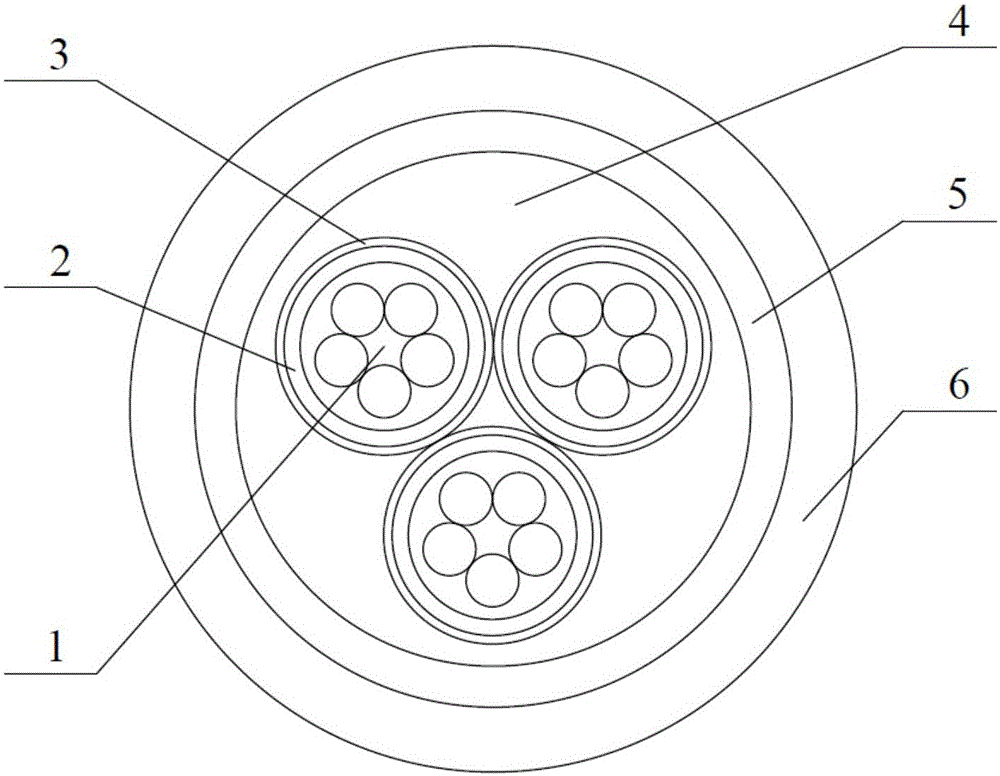

[0020] figure 1 It is a structural schematic diagram of the aging-resistant flame-retardant power cable of the present invention, referring to figure 1 , an aging-resistant and flame-retardant power cable proposed by the present invention, including N conductors 1, N≥3, the conductors 1 are respectively twisted into bundles by a plurality of wires, and are wrapped around the cladding layer 2 and the insulating layer in sequence on the outside 3 components, a flame-retardant filling material 4 is provided in the gaps between N conductors 1 to form a cable core, and an aluminum-plastic composite tape isolation layer 5 and a fireproof sheath layer 6 are sequentially wrapped on the outside of the cable core; wherein, the The fireproof sheath layer 6 is prepared from a modified natural rubber composite material, and the raw materials of the modified natural rubber composite material include by weight: 100 parts of natural rubber, 35 parts of EPDM rubber, ethylene-butylene elastic ...

Embodiment 2

[0022] refer to figure 1 , an aging-resistant and flame-retardant power cable proposed by the present invention, including N conductors 1, N≥3, the conductors 1 are respectively twisted into bundles by a plurality of wires, and are wrapped around the cladding layer 2 and the insulating layer in sequence on the outside 3 components, a flame-retardant filling material 4 is provided in the gaps between N conductors 1 to form a cable core, and an aluminum-plastic composite tape isolation layer 5 and a fireproof sheath layer 6 are sequentially wrapped on the outside of the cable core; wherein, the The fireproof sheath layer 6 is prepared from a modified natural rubber composite material, and the raw materials of the modified natural rubber composite material include by weight: 100 parts of natural rubber, 20 parts of EPDM rubber, ethylene-butylene elastic 15 parts of body, 10 parts of polyacrylonitrile fiber, 2 parts of stearic acid, 1 part of zinc oxide, 1.5 parts of dicumyl peroxid...

Embodiment 3

[0024] refer to figure 1 , an aging-resistant and flame-retardant power cable proposed by the present invention, including N conductors 1, N≥3, the conductors 1 are respectively twisted into bundles by a plurality of wires, and are wrapped around the cladding layer 2 and the insulating layer in sequence on the outside 3 components, a flame-retardant filling material 4 is provided in the gaps between N conductors 1 to form a cable core, and an aluminum-plastic composite tape isolation layer 5 and a fireproof sheath layer 6 are sequentially wrapped on the outside of the cable core; wherein, the The fireproof sheath layer 6 is prepared from a modified natural rubber composite material, and the raw materials of the modified natural rubber composite material include by weight: 100 parts of natural rubber, 28 parts of EPDM rubber, ethylene-butylene elastic 12 parts of body, 16 parts of polyacrylonitrile fiber, 1.8 parts of stearic acid, 1.3 parts of zinc oxide, 1.2 parts of dicumyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com