Oil-resistant rubber pipe and manufacturing process therefor

A technology of oil-resistant rubber and nitrile rubber, which is applied in the field of rubber, can solve the problems of insufficient mechanical strength and heat resistance, and achieve excellent heat resistance, stronger surface activity, and improved adhesion and oil resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

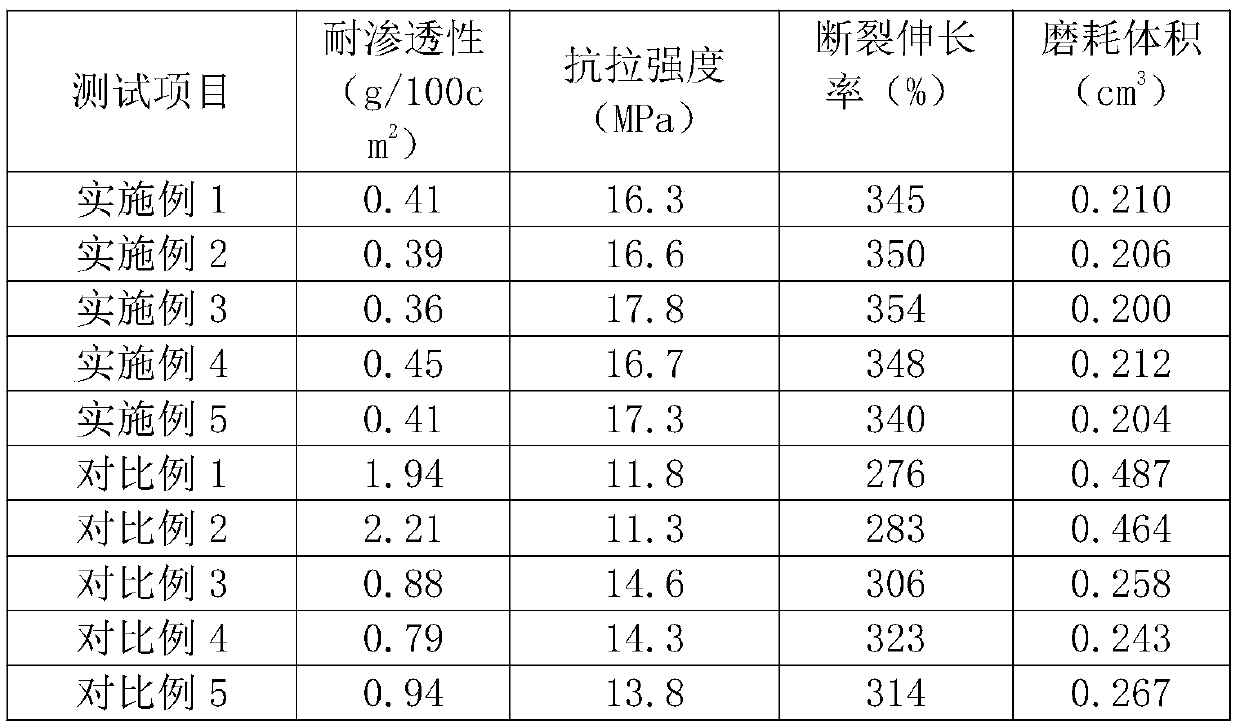

Examples

Embodiment 1

[0028] The oil-resistant rubber tube of the present embodiment, its raw material comprises by weight parts: 40 parts of nitrile rubber, 30 parts of silicone rubber, 3 parts of polyvinyl chloride, 7 parts of dicumyl peroxide, 1 part of sulfur, bissulfide tetrasulfide 4 parts of thiuram, 3 parts of benzoyl peroxide, 5 parts of zinc oxide, 1 part of calcium hydroxide, 2 parts of light calcium, 3 parts of white carbon black, 1 part of nano graphite, 2 parts of modified nano talcum powder, nano 2 parts of zinc sulfide, 3 parts of dibutyl phthalate, 1 part of plasticizer, 0.5 parts of anti-aging agent, 2 parts of accelerator.

[0029] Described white carbon black is fumed white carbon black, and described fumed white carbon black is through surface hydrophobic treatment, and fumed white carbon black specific surface area is 10m 2 / g.

[0030] The preparation method of the modified nano talc powder comprises: drying the talc powder with a particle size of 300-500nm at 100°C for 10 h...

Embodiment 2

[0042] The oil-resistant rubber tube of the present embodiment, its raw material comprises by weight: 60 parts of nitrile rubber, 40 parts of silicone rubber, 8 parts of polyvinyl chloride, 14 parts of dicumyl peroxide, 5 parts of sulfur, bissulfide 8 parts of thiuram, 8 parts of benzoyl peroxide, 10 parts of zinc oxide, 5 parts of calcium hydroxide, 6 parts of light calcium, 10 parts of white carbon black, 3 parts of nano graphite, 7 parts of modified nano talcum powder, nano 5 parts of zinc sulfide, 7 parts of dibutyl phthalate, 5 parts of plasticizer, 1.5 parts of anti-aging agent, 4 parts of accelerator.

[0043] Described white carbon black is fumed white carbon black, and described fumed white carbon black is through surface hydrophobic treatment, and fumed white carbon black specific surface area is 10m 2 / g.

[0044] The preparation method of the modified nano talc powder comprises: drying the talc powder with a particle size of 300-500nm at 110° C. for 12 hours, then...

Embodiment 3

[0056] The oil-resistant rubber tube of this embodiment, its raw materials include by weight: 50 parts of nitrile rubber, 35 parts of silicone rubber, 5.5 parts of polyvinyl chloride, 11 parts of dicumyl peroxide, 3 parts of sulfur, bissulfide 6 parts of thiuram, 5.5 parts of benzoyl peroxide, 7.5 parts of zinc oxide, 3 parts of calcium hydroxide, 4 parts of light calcium, 6.5 parts of white carbon black, 2 parts of nano graphite, 4.5 parts of modified nano talcum powder, nano 3.5 parts of zinc sulfide, 5 parts of dibutyl phthalate, 3 parts of plasticizer, 1 part of anti-aging agent, 3 parts of accelerator.

[0057] Described white carbon black is fumed white carbon black, and described fumed white carbon black is through surface hydrophobic treatment, and fumed white carbon black specific surface area is 10m 2 / g.

[0058] The preparation method of the modified nano talcum powder comprises: drying the talc powder with a particle size of 300-500nm at 105°C for 11 hours, then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com