Preparation of MnO-Cr2O3-graphene composite and application of MnO-Cr2O3-graphene composite in lithium ion battery negative electrodes

A composite material, graphene technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of capacity decay and volume expansion cannot be well improved, and achieve reduced capacity decay, excellent cycle performance, and good rate. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

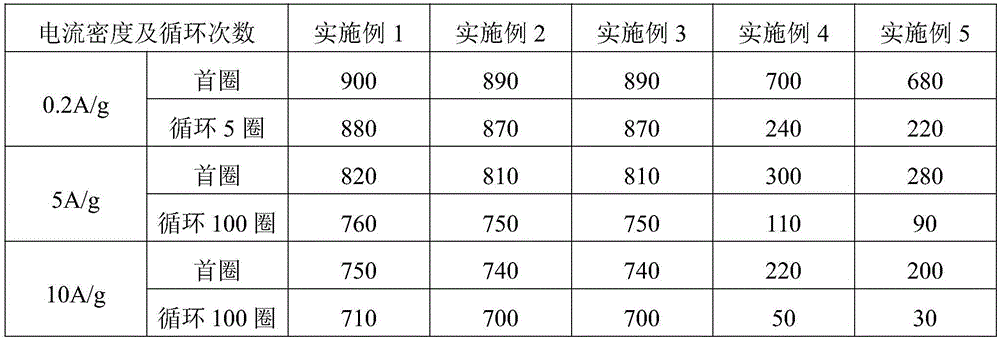

Examples

Embodiment 1

[0014] Example 1: MnO-Cr 2 O 3 - Preparation of graphene composites

[0015] A MnO-Cr 2 o 3 -The preparation method of graphene composite material, comprises the steps:

[0016] Step S1, synthesis of graphene oxide: take 0.5g of expanded graphite and 60ml of concentrated sulfuric acid and stir and mix, add 0.5g of sodium nitrate, and slowly add a mixture of 3g of potassium permanganate and potassium dichromate, stir overnight; remove the upper layer of the solution floating For unreacted expanded graphite, pour the mixed solution into 240ml triple-distilled water and stir. After the beaker is cooled, add 10ml of hydrogen peroxide with a mass fraction of 30% to obtain a bright yellow graphene oxide solution; centrifuge and wash with triple-distilled water for 4- 5 times, obtain brownish-yellow graphene oxide sol; Wherein, the ratio by weight of described potassium permanganate and potassium dichromate is 5:1;

[0017] Step S2, MnO-Cr 2 o 3 - Preparation of graphe...

Embodiment 2

[0018] Example 2: MnO-Cr 2 O 3 - Preparation of graphene composites

[0019] A MnO-Cr 2 o 3 -The preparation method of graphene composite material, comprises the steps:

[0020] Step S1, synthesis of graphene oxide: take 0.5g of expanded graphite and 60ml of concentrated sulfuric acid and stir and mix, add 0.5g of sodium nitrate, and slowly add a mixture of 3g of potassium permanganate and potassium dichromate, stir overnight; remove the upper layer of the solution floating For unreacted expanded graphite, pour the mixed solution into 240ml triple-distilled water and stir. After the beaker is cooled, add 10ml of hydrogen peroxide with a mass fraction of 30% to obtain a bright yellow graphene oxide solution; centrifuge and wash with triple-distilled water for 4- 5 times, obtain brownish-yellow graphene oxide sol; Wherein, the ratio by weight of described potassium permanganate and potassium dichromate is 4:1;

[0021] Step S2, MnO-Cr 2 o 3 - Preparation of graph...

Embodiment 3

[0022] Example 3: MnO-Cr 2 O 3 - Preparation of graphene composites

[0023] A MnO-Cr 2 o 3 -The preparation method of graphene composite material, comprises the steps:

[0024] Step S1, synthesis of graphene oxide: take 0.5g of expanded graphite and 60ml of concentrated sulfuric acid and stir and mix, add 0.5g of sodium nitrate, and slowly add a mixture of 3g of potassium permanganate and potassium dichromate, stir overnight; remove the upper layer of the solution floating For unreacted expanded graphite, pour the mixed solution into 240ml triple-distilled water and stir. After the beaker is cooled, add 10ml of hydrogen peroxide with a mass fraction of 30% to obtain a bright yellow graphene oxide solution; centrifuge and wash with triple-distilled water for 4- 5 times, obtain brownish yellow graphene oxide sol; Wherein, the ratio by weight of described potassium permanganate and potassium dichromate is 6:1;

[0025] Step S2, MnO-Cr 2 o 3 - Preparation of graph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com