Liquid crystalline polyurethane elastomer and method for producing same

A polyurethane elastomer and liquid crystal technology, applied in the direction of liquid crystal materials, chemical instruments and methods, etc., can solve the problems of no rubber elasticity, difficulty in liquid crystallinity, high temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

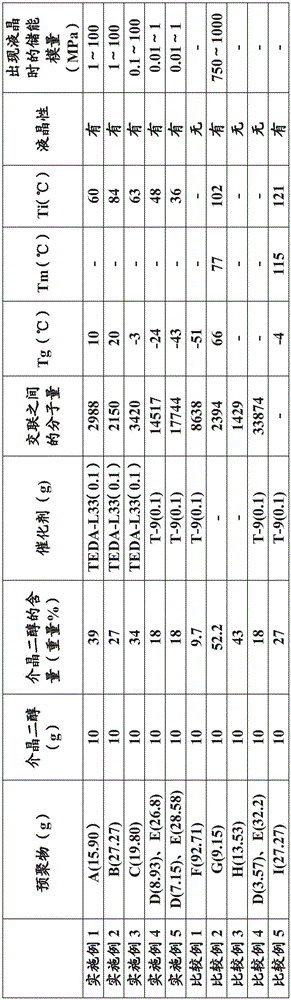

[0062] Hereinafter, the present invention will be described with reference to examples, but the present invention is not limited to these examples.

[0063] [measurement, evaluation method]

[0064] (Calculation of content of mesogenic diol)

[0065] The content of mesogenic diol in the polyurethane elastomer was calculated by the following formula.

[0066] Content of mesogenic diol (% by weight)={(weight of mesogenic diol) / (weight of all raw material components of polyurethane elastomer)}×100

[0067] (calculation of molecular weight between crosslinks)

[0068] The molecular weight between crosslinks of the polyurethane elastomer was calculated by the following formula.

[0069] Molecular weight between crosslinks = (weight of all raw material components of polyurethane elastomer) / (A × B)

[0070] A=(hydroxyl value of high molecular weight polyol with hydroxyl number 3 or more) / 56.1

[0071] B=(weight of high molecular weight polyol having 3 or more hydroxyl groups) / ...

manufacture example 1

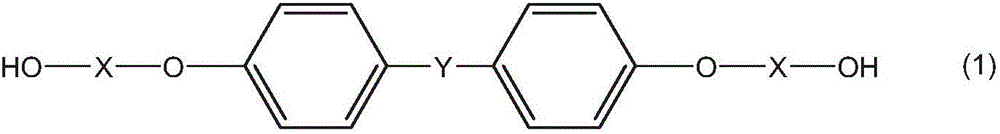

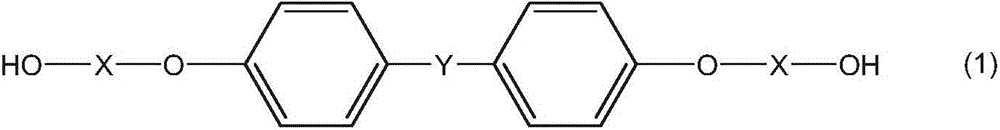

[0082] (Synthesis of mesogenic diols)

[0083]1.5 L of ethanol (manufactured by Nacalai Tesque) was put into the reaction vessel, and 120 g of sodium hydroxide (manufactured by Nacalai Tesque) was added thereto and dissolved. Subsequently, 140 g of 4,4'-biphenol (manufactured by Tokyo Chemical Industry Co., Ltd.) was added and heated under reflux for 30 minutes. Then, 451 g of 6-chloro-1-hexanol (manufactured by Tokyo Chemical Industry Co., Ltd.) was added dropwise, and the reaction solution was stirred at 90° C. for 12 hours. Next, the reaction solution was suction-filtered, and the obtained precipitate was washed with water, recrystallized with a mixed solvent (1 / 3) of DMF (manufactured by Mitsubishi Gas Chemical Co., Ltd.) / ethanol, and further washed with 1-butanol (manufactured by Nacalai Tesque Co., Ltd.). 170 g of white crystal 4,4'-bis(6-hydroxyhexyloxy)biphenyl was obtained by recrystallization.

manufacture example 2

[0085] (Synthesis of isocyanate-terminated prepolymer A)

[0086] 100 g of polypropylene glycol (manufactured by Asahi Glass Co., Ltd., trade name: Excenol 1030, number of hydroxyl groups, number average molecular weight 1000) and 74.4 g of 2,4-toluene diisocyanate (manufactured by Nippon Polyurethane Co., Ltd., trade name: T-100) were put into the reaction vessel. , stirred under a nitrogen stream, and reacted to obtain an isocyanate-terminated prepolymer A (NCO index: 3, isocyanate content: 13.7% by weight).

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com