Non-scaling heating assembly and evaporative crystallization device with same

A technology of heating components and heaters, applied in the direction of evaporation, separation and crystallization, general layout of crystallization devices, cleaning heat transfer devices, etc., can solve problems such as increasing raw material and energy consumption, shortening effective production time, and reducing equipment service life. Achieve the effects of improving resource utilization, solving scaling problems, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

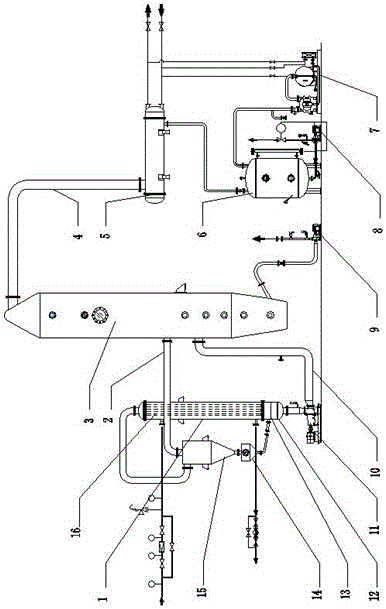

[0029] Embodiment 1, first add the inert solid particles to the particle storage tank 14 at one time according to the proportion, and open the steam inlet valve of the steam inlet on the heater 1 at the same time. 11 under the action of suction into the heater 1 for heat exchange, the inert solid particles in the particle storage tank 14 pass through the first coarse distributor 12 and the second fine distributor 13, and the inert solid particles are evenly distributed in each In the root heat exchange tube 16, under the action of the forced circulation pump 11, the feed liquid and inert solid particles form a fluidized boiling state of vapor, liquid and solid in the heat exchange tube 16, and the inert solid particles continuously pass through the liquid film boundary At the same time, the inert solid particles collide with the inner wall of the heat exchange tube 16, scour, polish, etc., which can effectively remove the dirt on the wall of the heating tube. The addition of i...

Embodiment 2

[0030]Example 2, first add the inert solid particles into the particle storage tank 14 at one time according to the predetermined ratio (the volume ratio of the inert solid particles to the stock solution is 5% to 15%), and turn on the vacuum unit 7 to vacuum the device, and at the same time Open the steam inlet valve of the steam inlet on the heater 1, and the stock solution at room temperature enters the lower circulation feed pipe 10 after being metered, and enters the heater 1 under the suction of the forced circulation pump 11 for heat exchange, and the inertness in the particle storage tank 14 The solid particles pass through the first coarse distributor 12 and the second fine distributor 13, and the inert solid particles (the size of the particles is 1~10mm) are evenly distributed in each heat exchange tube 16, and the feed liquid and the inert solid particles Under the action of the forced circulation pump 11, a fluidized boiling state of vapor, liquid and solid is form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com