Amine desulphurization method for refinery plant

A refinery amine and refinery gas technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of not fully utilizing the absorption potential of rich absorbents, desulfurization system operating costs, high energy consumption and investment, It does not consider the problem of mass exchange between rich and poor streams, and achieves the effects of preventing thermal degradation, reducing energy consumption, and reducing circulation volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

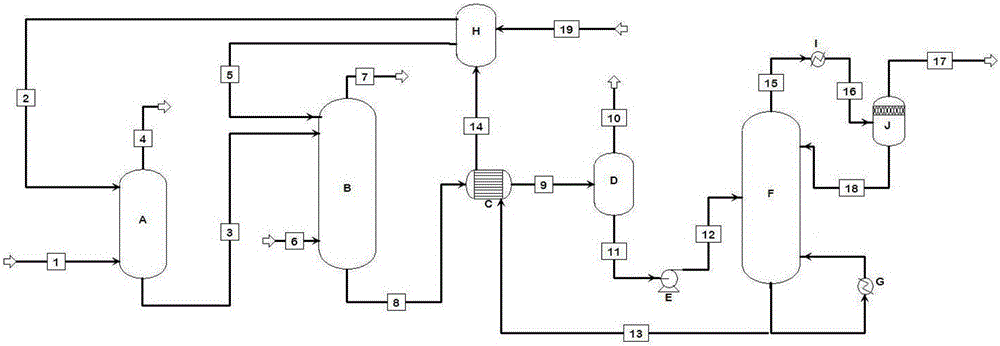

[0023] The desulfurization process is as follows:

[0024] The liquefied gas is sent to the lower part of the first refinery gas desulfurization tower (A) with a feed rate of 30000kg / h, a feed temperature of 35°C, and a feed pressure of 1.3 MPa. The operating temperature of the tower is 35°C, and the operating pressure is 1.112MPa, make it contact with countercurrent contact with absorbent MDEA (N-methyldiethanolamine) of 30wt% concentration that is imported from the tower top, obtain the purified liquefied gas stream (H 2 S=5mg / m 3 ≤50mg / m 3 ) and low H 2 S-loaded rich solution.

[0025] at 4900m 3 The feed amount per hour, the feed temperature of 38°C, and the feed pressure of 1.0MPa send the dry gas to the lower part of the second refinery gas desulfurization tower (B). The operating temperature of the tower is 36°C and the operating pressure is 0.85MPa , part or all of the low H from the bottom of the first refinery gas desulfurization tower (A) 2 The S-loaded rich l...

Embodiment 2

[0028] The desulfurization process in this example is the same as in Example 1 except for the operating parameters. The specific parameters are as follows: absorbent concentration 45wt%, liquefied gas feed rate 30000kg / h, feed temperature 30°C, feed pressure 1.1MPa, liquefaction The operating temperature of the gas desulfurization tower is 35°C, the operating pressure is 1MPa, and the dry gas feed rate is 4900m 3 / h, feed temperature 30°C, feed pressure 0.9MPa, dry gas desulfurization tower operating temperature 35°C, operating pressure 0.8MPa, rich liquid heat exchanger temperature 80°C, regeneration tower feed pump (E) boosted to 0.1MPa, the operating temperature of the solvent regeneration tower is 90°C, the operating pressure is 0.03MPa, the reboiler maintains the bottom temperature of the tower at 110°C, and the heat exchange cooling temperature of the rich liquid heat exchanger is 30°C.

Embodiment 3

[0030] The desulfurization process in this example is the same as in Example 1 except for the operating parameters. The specific parameters are as follows: absorbent concentration 15wt%, liquefied gas feed rate 30000kg / h, feed temperature 40°C, feed pressure 2.1MPa, liquefaction The operating temperature of the gas desulfurization tower is 45°C, the operating pressure is 2MPa, and the dry gas feed rate is 4900m 3 / h, feed temperature 40°C, feed pressure 1.1MPa, dry gas desulfurization tower operating temperature 45°C, operating pressure 1MPa, rich liquid heat exchanger temperature 110°C, regeneration tower feed pump (E) boosted to 0.3 MPa, the operating temperature of the solvent regeneration tower is 110°C, the operating pressure is 0.1MPa, the bottom temperature of the reboiler is maintained at 130°C, and the cooling temperature of the rich liquid heat exchanger is 50°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com