Waste heat recovery and hot air type energy-saving drying control system

A technology of waste heat recovery and drying control, applied in printing, printing machines, general parts of printing machinery, etc., can solve the problems of high price, waste of energy, danger of open fire, etc., and achieve the effect of saving heat and reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further explained below in conjunction with specific examples.

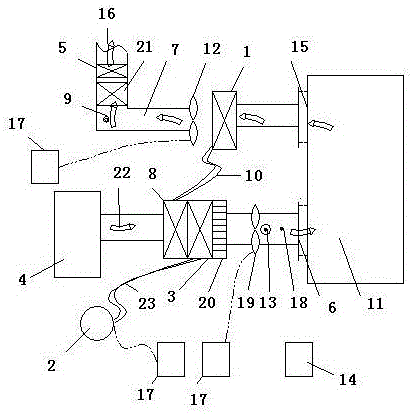

[0020] Such as figure 1 As shown, the waste heat recovery and hot air energy-saving drying control system includes drying box exhaust fan 12, exhaust air valve 21, axial flow fan 19, compressor 2, heat exchanger A 1 , heat exchanger C 3 , computer control Center 14, heat exchanger A 1 absorbs the thermal energy J 10 of the harmful waste gas 16 discharged from the air outlet 15 of the drying box 11, and the heat Z 23 produced by the compressor 2 acts on the heat exchanger C 3 together, and then sends it into the drying box 11 Air inlet 6.

[0021] The compressor 2 utilizes the Carnot principle to heat the cold air sucked in by the axial flow fan 19 through the air inlet 4 through the heat exchanger H 8 , superimpose the heat 10 exchanged by the heat exchanger 1 , and then send it into the inlet of the drying box 11 Tuyere 6.

[0022] Air temperature sensor 13 and air pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com