A preparing method of hydantoin epoxy resin

A technology of hydantoin epoxy resin and epichlorohydrin, which is applied in the field of organic chemical raw material manufacturing, can solve the problems of not being able to filter out sodium chloride particles, losing the superiority of hydantoin epoxy resin, and difficulty in recycling epichlorohydrin, etc. , to achieve high epoxy value, reduce the amount of "three wastes" and avoid side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

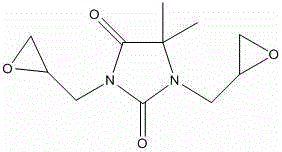

Image

Examples

Embodiment 1

[0036] A preparation method of hydantoin epoxy resin, the steps comprising:

[0037] (1) Add 0.3 mol (38.4 g) of 5,5-dimethylhydantoin and 1.8 mol (166.5 g) Epichlorohydrin, so that the molar ratio of 5,5-dimethylhydantoin and epichlorohydrin is 1:6;

[0038] (2) Add 0.48% (1 g) tetramethylammonium bromide of 204.9 g of the sum of the mass of 5,5-dimethylhydantoin and epichlorohydrin in the flask as the ring-opening catalyst of epichlorohydrin. Place the reactor in an oil bath, start stirring, feed nitrogen gas at a flow rate of 20mL / min, gradually increase the temperature of the oil bath, and heat the reactant to 115°C in 3 hours to carry out the ring-opening reaction of epichlorohydrin;

[0039] (3) After 3 hours of reaction, stop the heating of the oil bath, maintain the stirring state, cool the reaction solution to 30°C, and then stop the nitrogen flow;

[0040] (4) Add 0.93 times (190.2 g) of acetone as a solvent to the sum of 204.9 g of 5,5-dimethylhydantoin and epichl...

Embodiment 2

[0051] A preparation method of hydantoin epoxy resin, the steps comprising:

[0052] (1) Add 0.3 mol (38.4 g) of 5,5-dimethylhydantoin and 1.5 mol (138.8 g) Epichlorohydrin, so that the molar ratio of 5,5-dimethylhydantoin and epichlorohydrin is 1:6;

[0053] (2) Add 0.28% (0.5g) tetramethylammonium chloride of 177.2g of the sum of 5,5-dimethylhydantoin and epichlorohydrin to the flask as the ring-opening catalyst of epichlorohydrin, Place the reactor in an oil bath, start stirring, feed nitrogen gas at a flow rate of 15mL / min, gradually increase the temperature of the oil bath, and heat the reactant to 116°C in 3.5 hours to carry out the ring-opening reaction of epichlorohydrin ;

[0054] (3) After reacting for 3.5 hours, stop the heating of the oil bath, maintain the stirring state, cool the reaction solution to 28°C, and then stop the nitrogen flow;

[0055] (4) Add 1.08 times (190.7g) tetrahydrofuran as a solvent to the sum of 177.2g of the mass of 5,5-dimethylhydantoin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com