Liquid crystal polyester and its molded composition and use

A technology of molding composition and liquid crystal polyester, which is applied in the field of liquid crystal polyester and the molding composition composed of it, and can solve the problems affecting the application of liquid crystal polymer, mold filling dissatisfaction, resin fluidity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

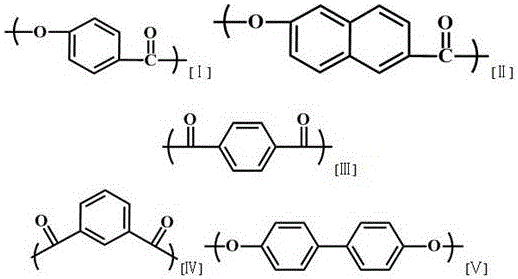

[0063] Add the following monomer raw materials, acylating agent and catalyst to the polymerization reaction device equipped with agitator, reflux condenser, monomer feeding port, nitrogen inlet, thermometer and torque sensor.

[0064] (I) p-Hydroxybenzoic acid 1298.4 g (47 mol %) HBA

[0065] (Ⅱ) 6-hydroxy-2-naphthoic acid 112.9 g (3mol%) HNA

[0066] (Ⅲ) Terephthalic acid 731g (22mol%) TA

[0067] (IV) 99.7 g (3 mol%) IA of isophthalic acid

[0068] (Ⅴ) 4,4'-biphenol 931.1 g (25mol %) BP

[0069] Acylating agent: acetic anhydride 2041 g

[0070] Catalyst: Magnesium acetate 103 mg

[0071] After the feeding is completed, completely replace the atmosphere in the reaction vessel with nitrogen, raise the temperature of the reaction system to 140°C under the protection of nitrogen, and keep the nitrogen pressure at 0.2MPa, and maintain this temperature for 2 hours to carry out the acylation reaction; After the reaction is over, turn on the vacuum pump to reduce the pressure i...

Embodiment 2-5

[0072] Example 2-5 : According to the formula in Table 1, after the acylation reaction finishes, open the vacuum pump to decompress the pressure in the reactor to 10KPa-30KPa, and quickly discharge acetic acid and unreacted acetic anhydride molecules from the rectifying column to meet the technical requirements of rapid heating. When the amount of acetic acid received reaches more than 50% of the theoretical value, quickly raise the temperature to 210°C, maintain this reduced pressure condition and raise the temperature of the reaction system to the highest temperature of 370°C within 6 hours. During this period, acetic acid, especially phenol, etc. are continuously discharged to cause molecular chain weight. Arrangement and branched by-product small molecules, then decompressed to 60KPa in 30 minutes; All the other are the same as embodiment 1;

Embodiment 6-12

[0073] Example 6-12 : According to the formula in Table 1, after the acylation reaction finishes, open the vacuum pump to decompress the pressure in the reactor to 10KPa-30KPa, and quickly discharge acetic acid and unreacted acetic anhydride molecules from the rectifying column to meet the technical requirements of rapid heating. When the amount of acetic acid received reaches more than 50% of the theoretical value, quickly raise the temperature to 220°C, maintain this reduced pressure condition and raise the temperature of the reaction system to the highest temperature of 380°C within 6 hours, during which the continuous discharge of acetic acid, especially phenol, etc. Arrange and branched by-product small molecules, then decompress to 70KPa in 30 minutes; All the other are the same as embodiment 1; The fusing point of this liquid crystal polyester, melt viscosity, storage modulus release rate, rod-like fluid length are listed in table 1 middle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com