A kind of automobile interior decoration plate prepared by using waste polypropylene material

A technology of waste polypropylene and polypropylene materials, applied in the field of automobile interior decoration, can solve the problems of low operating temperature of PU board or PP wood powder board, easy oxidation and aging, no impact resistance, etc., and achieves strong resistance to organic solvents. , strong acid and alkali resistance, not easy to oxidize and aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Roughly wash and rinse the recovered waste polypropylene plastics in the pool, and then put them into the rotary washing machine and add cleaning agent for 1 hour.

[0024] (2) Dehydrate and dry the cleaned waste polypropylene material through a dehydrator.

[0025] (3) Put the waste polypropylene material after dehydration and drying into a fine grinder and crush it into small pieces of about 2 cm.

[0026] (4) Put the pulverized small piece of waste polypropylene material into the parent-child wire drawing pelletizer, and thermally cut it into small pieces of about 10mm under the condition of decomposition temperature of 100°C.

[0027] (5) Add 5 kg of modified phenolic resin to 1.67 kg of absolute ethanol to dissolve it to make a resin ethanol solution.

[0028] (6) Then mix 1 kg of lanthanum oxide, 0.3 kg of europium oxide, 0.4 kg of cerium oxide, 0.8 kg of praseodymium oxide, 0.5 kg of rubidium oxide, 0.45 kg of neodymium oxide, and 0.5 kg of samarium oxide, f...

Embodiment 2

[0031] (1) Roughly wash and rinse the recovered waste polypropylene plastics in the pool, and then put them into the rotary washing machine and add cleaning agent for 1 hour.

[0032] (2) Dehydrate and dry the cleaned waste polypropylene material through a dehydrator.

[0033] (3) Put the waste polypropylene material after dehydration and drying into a fine grinder and crush it into small pieces of about 2 cm.

[0034] (4) Put the pulverized small piece of waste polypropylene material into the parent-child wire drawing pelletizer, and thermally cut it into small pieces of about 10mm at the decomposition temperature of 180°C.

[0035] (5) Add 15kg of modified phenolic resin to 5kg of absolute ethanol to dissolve, and make resin ethanol solution.

[0036] (6) 1.2kg of lanthanum oxide, 0.22kg of europium oxide, 0.3kg of cerium oxide, 1.26kg of praseodymium oxide, 0.4kg of rubidium oxide, 0.22kg of neodymium oxide, and 0.4kg of samarium oxide were fully mixed under a high-speed m...

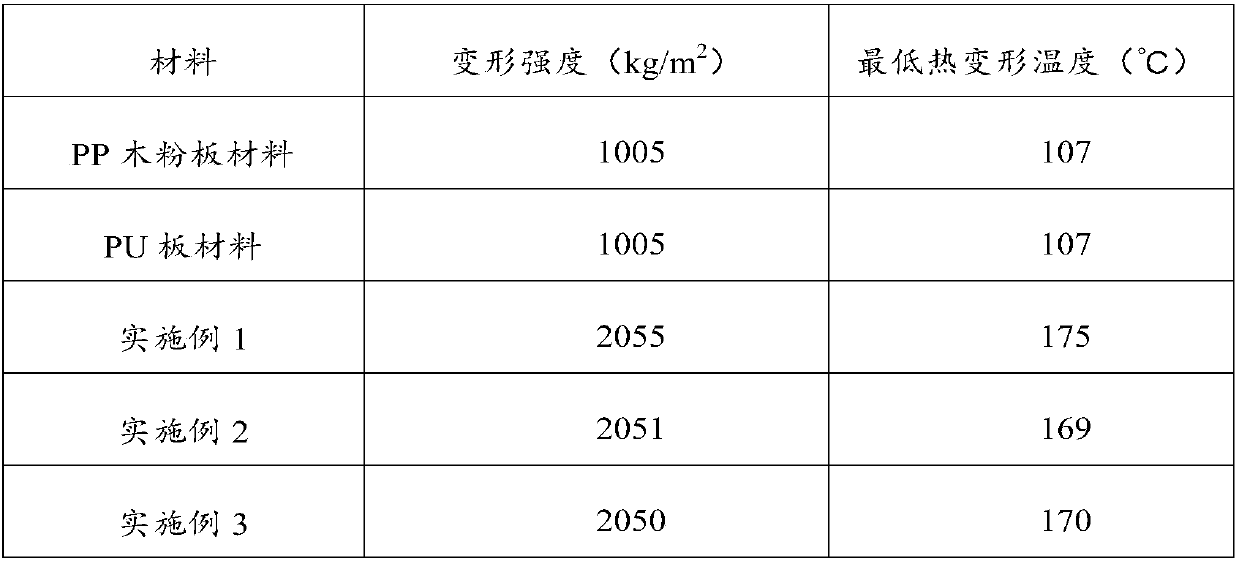

Embodiment 3

[0039] (1) Roughly wash and rinse the recovered waste polypropylene plastics in the pool, and then put them into the rotary washing machine and add cleaning agent for 1 hour.

[0040] (2) Dehydrate and dry the cleaned waste polypropylene material through a dehydrator.

[0041] (3) Put the waste polypropylene material after dehydration and drying into a fine grinder and crush it into small pieces of about 2 cm.

[0042] (4) Put the pulverized small piece of waste polypropylene material into the parent-child wire drawing and pelletizing machine, and thermally cut it into small pieces of about 10mm at the decomposition temperature of 140°C.

[0043] (5) Add 10kg of modified phenolic resin to 3.33kg of absolute ethanol to dissolve it to make a resin ethanol solution.

[0044] (6) 1.295kg of lanthanum oxide, 0.185kg of europium oxide, 0.185kg of cerium oxide, 1.11kg of praseodymium oxide, 0.185kg of rubidium oxide, 0.37kg of neodymium oxide, and 0.37kg of samarium oxide were fully m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com