Method for treating polluted water by utilizing solid waste steel slag

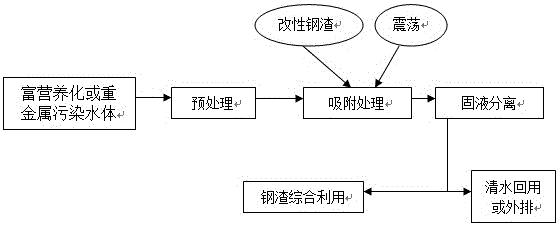

A technology for steel slag and water body, applied in the field of resources and environment, can solve the problems of heavy metal enrichment, water body pollution, affecting the comprehensive utilization of water resources, etc., and achieves the effects of low treatment cost, simple and convenient operation, and good treatment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Water samples from the Tanglangchuan River in Anning, Kunming, Yunnan (COD: 36.69mg / L, TP: 0.258mg / L, TN: 1.383mg / L) were intercepted by conventional grids to remove particulate impurities in the wastewater, Ensure that the wastewater can meet the requirements of adsorption treatment, and the pH of the river water is neutral without adjustment;

[0026] (2) In the wastewater pretreated in step (1), add the modified steel slag in an amount of solid-liquid ratio of 30g / L, then carry out the adsorption reaction at room temperature for 120min at a shaking stirring speed of 200r / min, and then Conventional filtration solid-liquid separation, get water.

[0027] The modified steel slag is made by adding nitric acid with a concentration of 40v / v%, modifying according to the ratio of steel slag to acid volume of 1:3, washing with water until neutral, and then drying in an oven at 90°C.

[0028] Final test: COD is 17.98mg / L, removal rate is 50.99%; total phosphorus is not de...

Embodiment 2

[0030] (1) Take the water sample 1 sent for inspection by a certain unit as an example: pH=1.62, COD is 99mg / L, As0.8674mg / L, Pb0.508mg / L, and the particles in the wastewater are removed by conventional filtration Impurities, to ensure that the wastewater can meet the requirements of adsorption treatment, and add potassium hydroxide solution to adjust the pH of the wastewater to 7.97;

[0031] (2) Add the modified steel slag to the wastewater pretreated in step (1) at a solid-to-liquid ratio of 25g / L, then carry out adsorption reaction for 60min at a shaking stirring speed of 180r / min, and then undergo a conventional Suction filtration solid-liquid separation, get water.

[0032] The modified steel slag is made by adding nitric acid with a concentration of 90v / v%, modifying according to the ratio of steel slag to acid volume of 1:4, washing with water to neutrality, and then drying in an oven at 80°C.

[0033] The final effluent COD is 5.44mg / L, the removal rate is 94.51%, As...

Embodiment 3

[0035] (1) Take the water sample 2 sent for inspection by a certain unit as an example: pH=2.04, COD is 20mg / L, As0.8598mg / L, Pb0.22mg / L, and the particles in the wastewater are removed by conventional filtration impurities, to ensure that the wastewater can meet the requirements of adsorption treatment, and add sodium hydroxide solution to adjust the pH of the wastewater to 6.35;

[0036](2) In the wastewater pretreated in step (1), add the modified steel slag according to the solid-liquid ratio of 35g / L, then carry out the adsorption reaction for 100min at the shaking stirring speed of 150r / min, and then pass through the conventional Suction filtration solid-liquid separation, get water.

[0037] The modified steel slag is made by adding nitric acid with a concentration of 70v / v%, modifying according to the ratio of steel slag to acid volume of 1:4, washing with water until neutral, and then drying in an oven at 80°C.

[0038] The final effluent COD is 6.63mg / L, the removal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com