Biomass-based polymer coated controlled release fertilizer and production method thereof

A technology of controlled-release fertilizer and coating, which is applied in layered/coated fertilizers, organic fertilizers, fertilizer mixtures, etc., can solve the problem that petroleum resources are difficult to build a virtuous cycle of controlled-release fertilizers, and achieve secondary utilization, controlled-release, etc. Good performance, solve the effect of refractory degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1, the preparation of co-liquefaction coating liquid and its controlled-release fertilizer

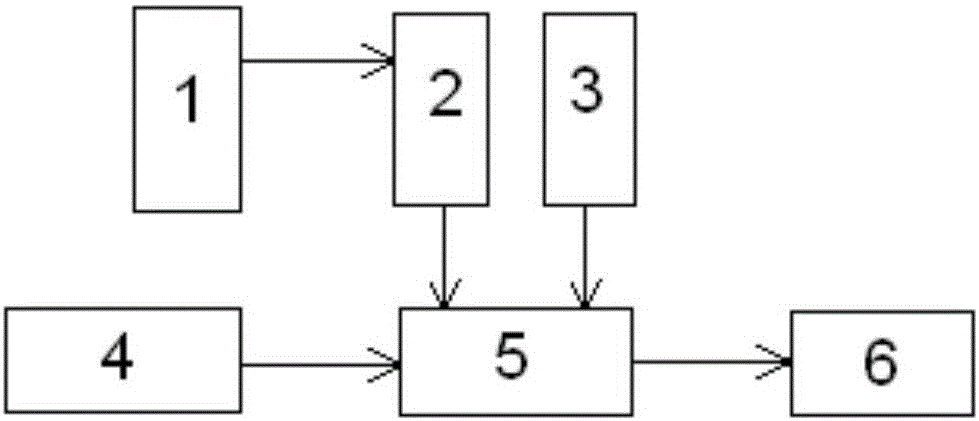

[0049] 1) According to such as figure 1 The process shown in the preparation of the co-liquefaction coating solution and its controlled release fertilizer, the specific steps are as follows: 100g of corn stalk powder with a particle size of 80 mesh, 48g of cornstarch, a liquefaction agent composed of 350g of polyethylene glycol 400 and 50g of glycerin, 8g of 98% concentrated sulfuric acid catalyst, mixed uniformly in a reaction kettle equipped with mechanical stirring and a condenser, then heated up to 160°C under constant stirring, carried out a co-liquefaction reaction for 100 minutes, then cooled with an ice-water bath to terminate the reaction, and precipitated to obtain 500g Co-liquefaction supernatant (that is, co-liquefaction), the residue left in the system continues to co-liquefaction;

[0050] 2) To 500g of the co-liquefaction supernatant (that is, the co-l...

Embodiment 2

[0053] Embodiment 2, the preparation of co-liquefaction coating liquid and its controlled-release fertilizer

[0054] 1) According to such as figure 1 The process shown to prepare the co-liquefaction coating solution and its controlled-release fertilizer is as follows: liquefy 160g of rice straw powder with a particle size of 40 mesh, 40g of corn starch, 320g of polyethylene glycol 200 and 80g of ethylene glycol. agent, 16g of 98% concentrated sulfuric acid catalyst, after mixing uniformly in a reaction kettle equipped with mechanical stirring and a condenser tube, the temperature was raised to 180°C under constant stirring, and the co-liquefaction reaction was carried out for 40 minutes, and then cooled with a cold water bath to terminate the reaction and precipitate Obtain 546g co-liquefaction supernatant (also co-liquefaction thing), the residue that stays in the system continues co-liquefaction;

[0055] 2) Add 16.9g of auxiliary microcrystalline wax, 10.3g of triethylene...

Embodiment 3

[0058] Embodiment 3, the preparation of co-liquefaction coating liquid and its controlled-release fertilizer

[0059] 1) According to such as figure 1 The process shown in the preparation of co-liquefied coating solution and its controlled release fertilizer, the specific steps are as follows: 140g of peanut shell powder with a particle size of 60 mesh, 47g of corn starch, liquefied with 327g of polyethylene glycol 600 and 73g of diethylene glycol agent, 12g of 98% concentrated sulfuric acid catalyst, after mixing evenly in a reaction kettle equipped with mechanical stirring and a condenser, the temperature was raised to 140°C under constant stirring, and the co-liquefaction reaction was carried out for 120 minutes, and then the reaction was terminated by cooling in an ice-water bath, and the precipitation Obtain 530g co-liquefaction supernatant (that is, co-liquefaction), and the residue left in the system continues to co-liquefy;

[0060] 2) In 530g of co-liquefaction super...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com