Recombinant plasmid and recombinant yeast strain and establishing method and application thereof

A recombinant plasmid, paracoccus technology, applied in the field of genetic engineering, can solve the problems of high complexity and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Example 1: Acquisition of foreign genes

[0066] Find Aa crtZ, Asp crtZ, Eu crtZ, Pa crtZ, Ps crtZ, Ss crtZ, B.SD212crtZ, B.DC263crtZ, HpChyb, Aa crtW, Asp crtW, CrBKT, Gv crtW, Np73102crtW, Nsp7120crtW, BSD212crtW, The corresponding amino acid sequences of B.SD212, B.DC263crtW, ReSH019crtO, and SDC18crtW were optimized, and the codons were optimized. Symmetrical BsaI and NotI restriction sites were introduced at both ends, namely NotI-BsaI-crtZ / crtW-BsaI-NotI. EcoR V was blunt-ended into pUC57 or pUC57-Kan vector to obtain pUC57-Kan / pUC57-crtZ and pUC57-Kan / pUC57-crtW, which were synthesized by GenScript.

Embodiment 2

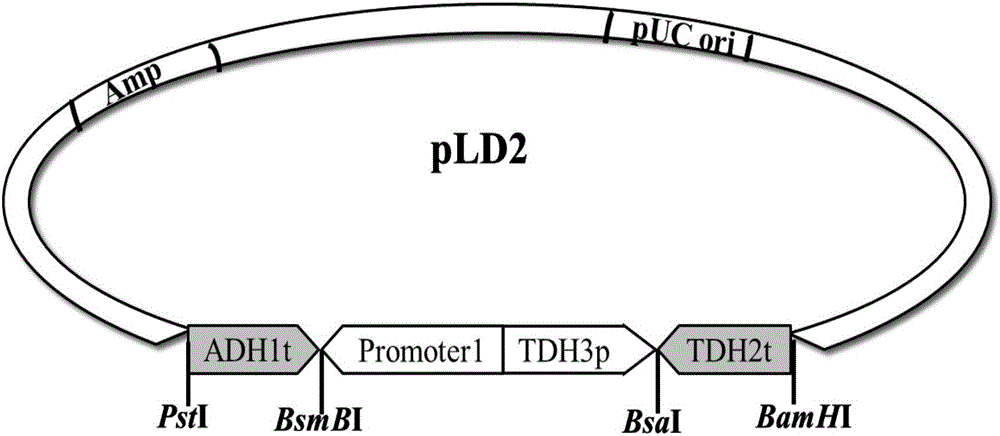

[0067] Example 2: Acquisition of ADH1t-FBA1p / TEF1p-TDH3p-TDH2t Fragment

[0068] ADH1t, FBA1p, TDH3p, TDH2t and TEF1p were amplified by PCR using the genome of Saccharomyces cerevisiae BY4741 as a template, and then spliced by OE-PCR to obtain ADH1t-FBA1p / TEF1p-TDH3p-TDH2t with PstI and BamHI restriction sites at both ends Fragment, in which a BsmBI restriction site was added between FBA1p / TEF1p and ADH1t, and a BsaI restriction site was added between TDH3p and TDH2t; then digested with restriction endonucleases PstI and BamHI, and then connected to the PLD2 vector to obtain PLD2-ADH1t-FBA1p / TEF1p-TDH3p-TDH2t spare.

Embodiment 3

[0069] Example 3: Insertion of foreign genes

[0070] The pUC57-Kan / pUC57-crtW in Example 1 was digested with BsaI and then connected to the PLD2-ADH1t-FBA1p / TEF1p-TDH3p-TDH2t vector that was also digested with BsaI to obtain PLD2-ADH1t-FBA1p / TEF1p-TDH3p- crtW-TDH2t, then pUC57-Kan / pUC57-crtZ in Example 1 was digested with BsaI and then connected to PLD2-ADH1t-FBA1p / TEF1p-TDH3p-crtW-TDH2t digested with BsmBI in turn to obtain PLD2-ADH1t -crtZ-FBA1p / TEF1p-TDH3p-crtW-TDH2t.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com