Environment-friendly preparation process of high-purity and superfine anhydrous magnesium carbonate

An anhydrous magnesium carbonate, environment-friendly technology, applied in the direction of magnesium carbonate, etc., can solve problems such as the inability to prepare high-purity ultrafine anhydrous magnesium carbonate, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Preparation of heavy magnesium water: After the hydration suspension of lightly burned powder is carbonized by carbon dioxide, add TMT-15 (organic sulfur heavy metal scavenger 1.3.5-triazine-2.4.6-trithiol trisodium salt, 15%) 120ppm , to remove iron ions and heavy metal impurities, and use a precision filter to separate the suspension from solid to liquid, remove solid impurities to obtain clear and transparent heavy magnesium water, the concentration of magnesium ions is 0.25mol / L, the content of iron ions is 30ppm, and the content of heavy metal ions is 5ppm.

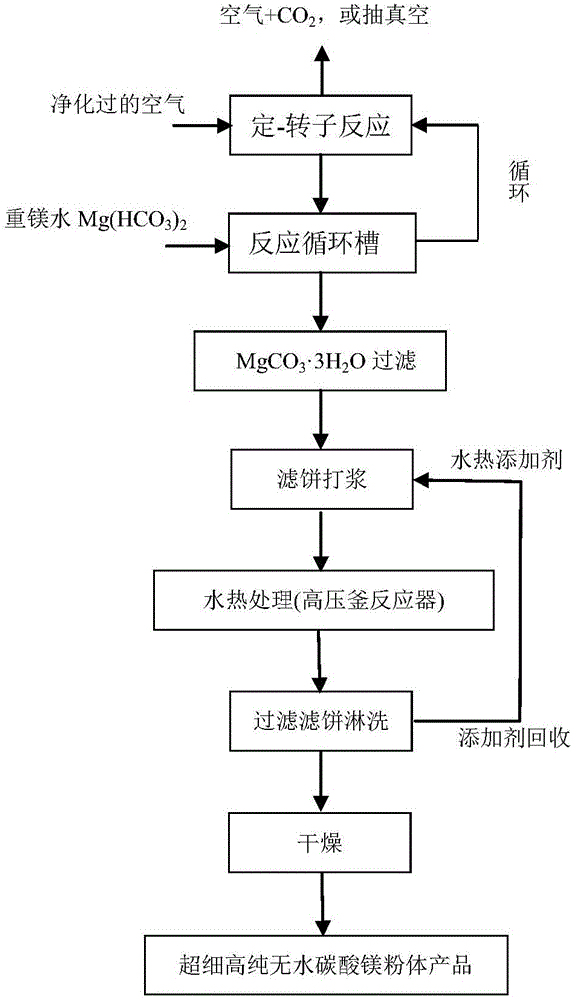

[0025] Preparation of magnesium carbonate trihydrate by high-gravity technology: Heavy magnesium water is transported to the circulation tank of the high-gravity stator-rotor reactor, the stator-rotor reactor motor, circulation pump and blower or vacuum pump are started, and the heavy magnesium water enters the stator-rotor reactor Reverse contact with purified air strengthens the transfer process, decomposes t...

Embodiment 2

[0029] Preparation of heavy magnesium water: configure low-quality magnesium hydroxide powder into a slurry with a content of 22 g / liter, after carbon dioxide carbonization reaction, add TMT-15 (organic sulfur heavy metal scavenger 1.3.5-triazine-2.4.6 -trithiol trisodium salt, 15%) 120ppm, remove iron ions and heavy metal impurities, use a precision filter to separate the suspension from solid to liquid, remove solid impurities to obtain clear and transparent heavy magnesium water, the concentration of magnesium ions is 0.20mol / L , iron ion content is 30ppm, heavy metal ion 5ppm.

[0030] Preparation of magnesium carbonate trihydrate by high-gravity technology: heavy magnesium water is transported to the circulation tank of the high-gravity stator-rotor reactor, the motor and vacuum pump of the stator-rotor reactor are started, and the heavy magnesium water is decomposed to produce magnesium carbonate trihydrate precipitation and carbon dioxide, carbon dioxide Gas is exhauste...

Embodiment 3

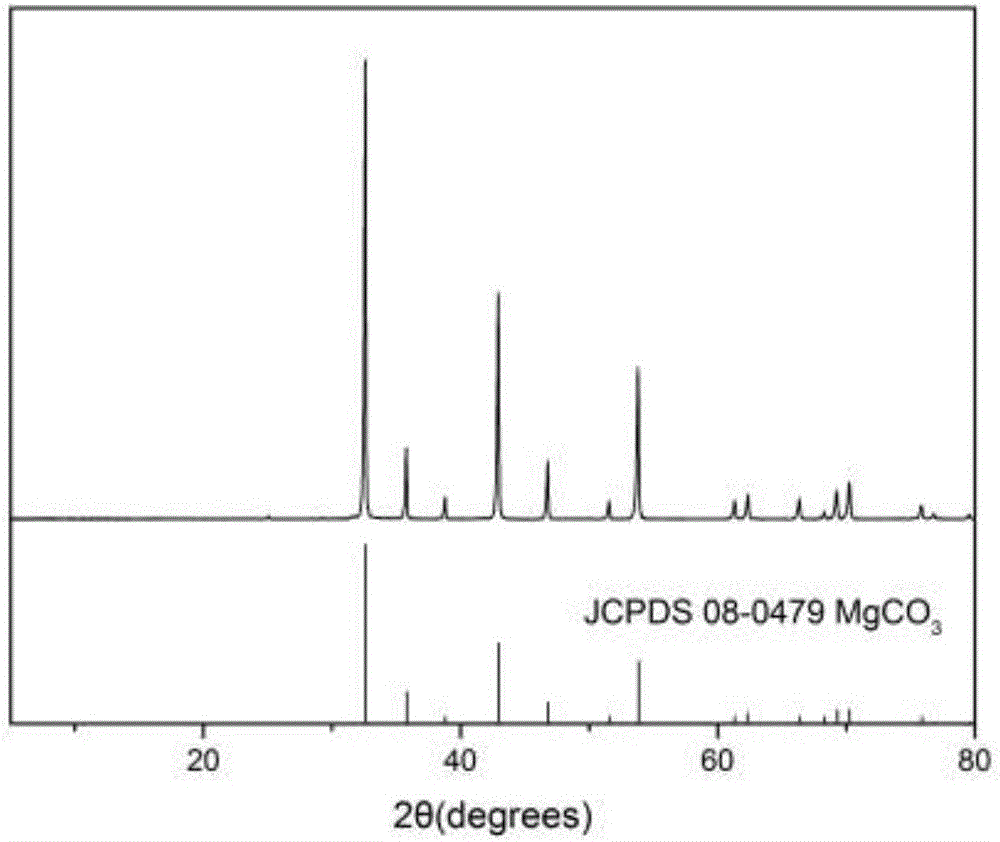

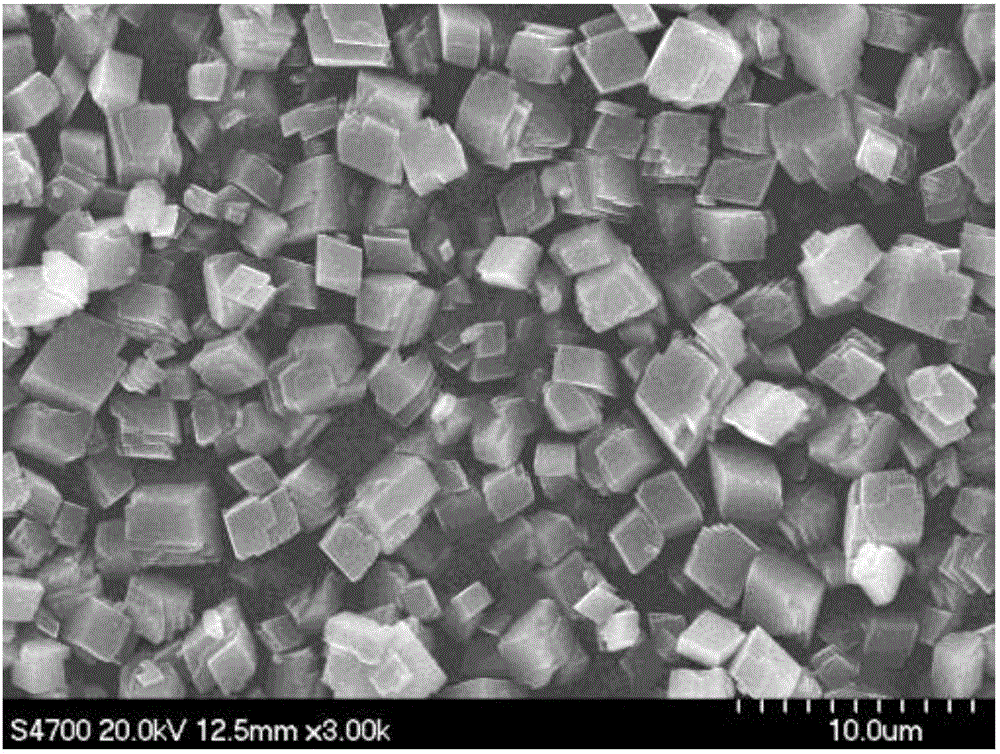

[0032] Embodiment 3: The difference between the preparation operation steps and Example 1 is that the gas-liquid ratio of feeding air is 50, and the reaction time is 0.5 hour during the preparation of magnesium carbonate trihydrate. The obtained sample is single-phase anhydrous magnesium carbonate, the particles are uniform and well-dispersed, and the particle size is concentrated at about 2 μm. After chemical analysis, the contents of each substance in the powder are: magnesium oxide (MgO) = 47.1%, calcium oxide (CaO) =0.025%, iron (Fe 2 o 3 )=100ppm, heavy metal (calculated as Pb)≤10ppm, chloride≤100ppm, sulfate radical≤100ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com