Anionic surface active initiator and preparation method thereof

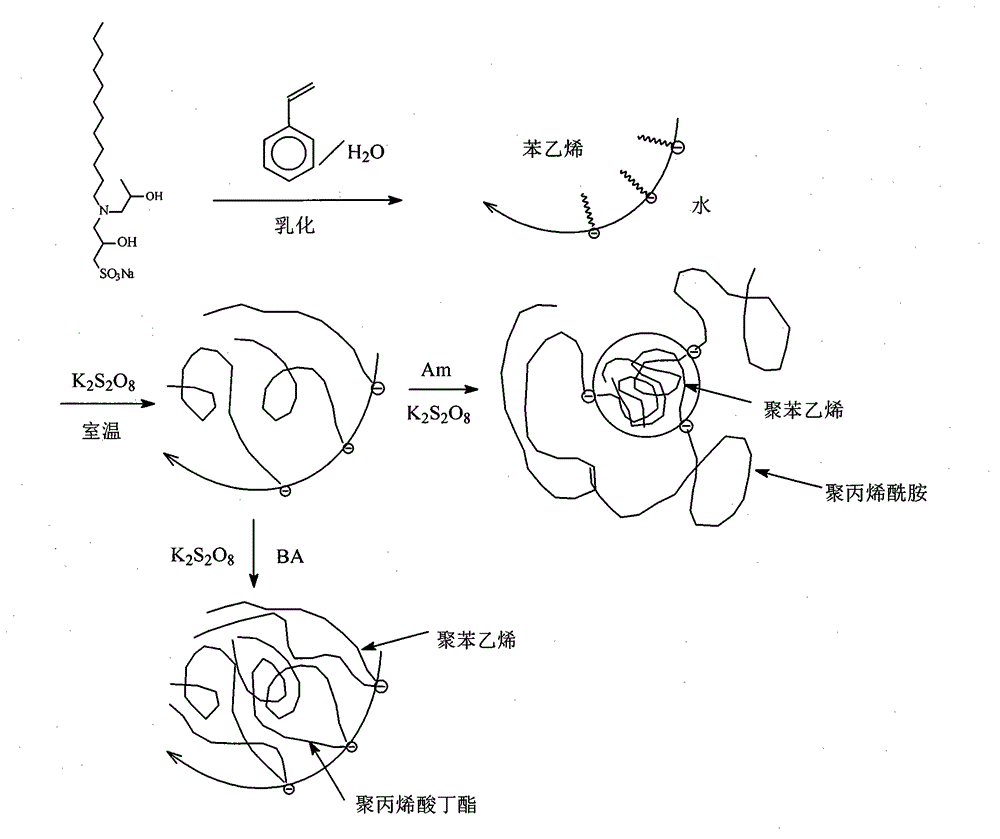

A technology of surface activity and initiator, which is applied in the field of polymer material synthesis, can solve the problems of insufficient functionality of block polymers, inability to achieve cross-phase polymerization, insufficient improvement of initiators, etc., and achieve fast polymerization reaction and high conversion rate , The effect of mild and controllable reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with embodiment the present invention is described in further detail.

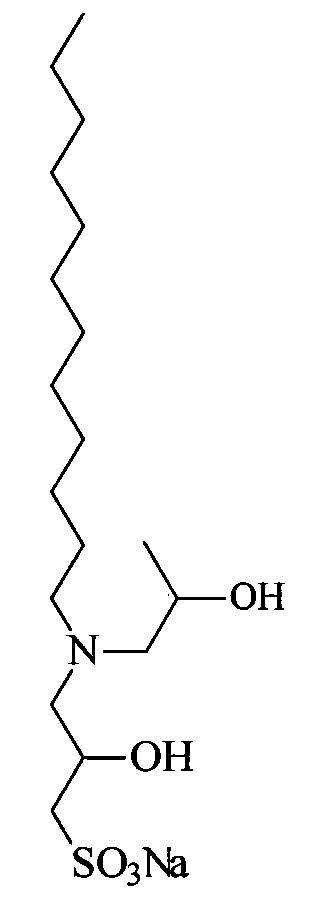

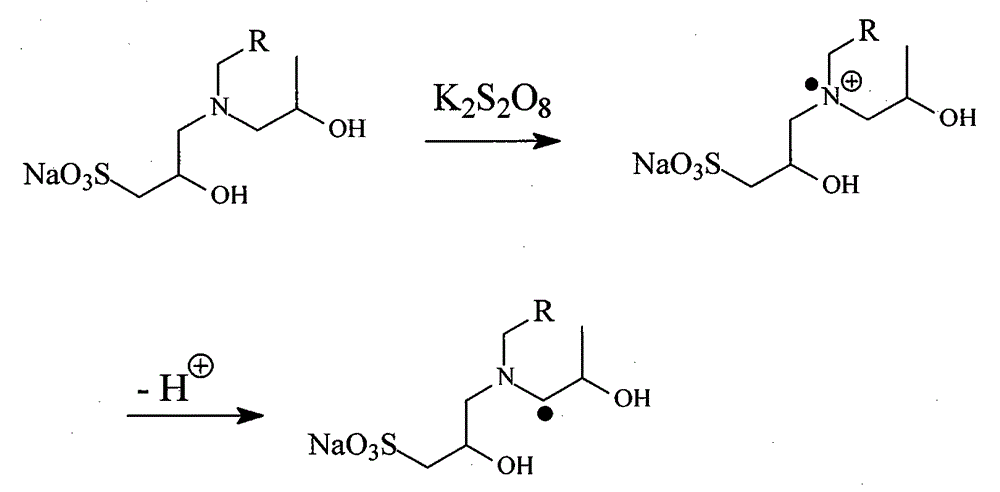

[0020] Preparation of anionic surfactant initiator:

[0021] 1. Dissolve sodium sulfite in water to make a 15-20wt.% concentrated solution, put it in a jar, add excess epichlorohydrin at room temperature, and the molar ratio of sodium sulfite to epichlorohydrin is 1:1.1~ 1:1.2 range, react at room temperature for 12 to 15 hours, and often stir to obtain a large amount of colorless crystals of sodium 2-hydroxy-3-chloropropanesulfonate, the yield is almost 100%, after filtering, wash with a small amount of ethanol and dry spare;

[0022] 2. Mix and dissolve dodecylamine and ethylene glycol according to the weight ratio of 1:3.5~1:4, then add the above-mentioned sodium 2-hydroxy-3-chloropropanesulfonate, heat to dissolve and mix with dodecylamine at 75~80 Reaction at ℃ temperature, the molar ratio of dodecylamine and sodium 2-hydroxyl-3-chloropropanesulfonate is in the range of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com