A method of making crumpled colored dental paper scarf paper

A manufacturing method and color technology, applied in papermaking, paper, textiles and papermaking, etc., can solve the problems of limited use range and quantity, poor liquid absorption and liquid retention, not soft and delicate enough, etc., to achieve easy control of production process and production cost. Low, paper delicate and soft effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

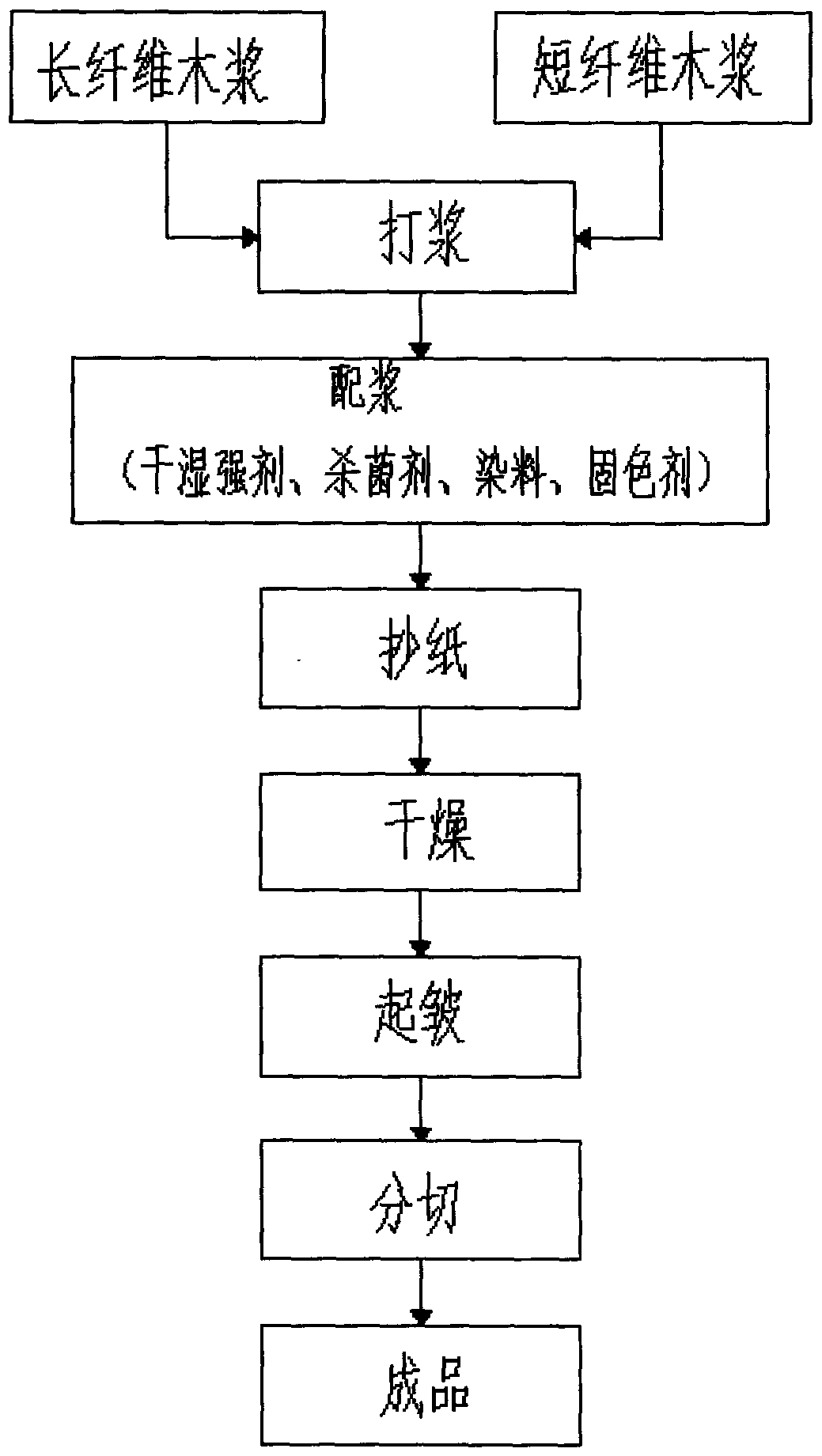

[0017] see figure 1 , a kind of manufacture method of the colored dental paper scarf paper of crumpling, concrete steps are as follows: (1) length is respectively the wood pulp waste cup paper long fiber that length is 2.4mm and the wood pulp waste cup paper that length is 0.6mm Short fibers are crushed, and the weight ratio of long fibers to short fibers is 60:35; (2) The crushed long fibers and short fibers are mixed and beaten, and the degree of beating is controlled at 35°SR; (3) per ton of paper Weigh 20kg of polyamide epichlorohydrin resin wet strength agent, 1.0kg of dry strength agent, 9kg of neutral dye, 10kg of color fixing agent and add it to the pulp, then add 0.1kg of bactericide, and carry out high-temperature sterilization at 120°C; Rotary wire or fourdrinier paper machine is used for papermaking, the concentration on the net is 0.08%, and the speed is 75m / min. When the paper sheet is dried on the drying cylinder until the dryness reaches 90%, wrinkling is carr...

Embodiment 2

[0020] A kind of manufacture method of the colored dental paper scarf paper of crumpling, concrete steps are as follows: (1) the long fiber of waste wood pulp masking paper that length is 2.6mm and the short fiber of waste wood pulp masking paper that length is 0.8mm respectively The fiber is crushed, and the weight ratio of long fiber and short fiber is 70:30; (2) the long fiber and short fiber after crushing are mixed and beaten, and the beating degree is controlled at 38°SR; (3) each ton of paper weighs Add 35kg of polyamide epichlorohydrin resin wet strength agent, 1.5kg of dry strength agent, 13.5kg of neutral dye, 1.5kg of color fixing agent into the pulp, then add 0.2kg of fungicide and perform high temperature sterilization at 140°C; Papermaking is carried out on a net or fourdrinier paper machine, the concentration of the netting is 0.10%, and the speed is 80m / min. When the paper sheet is dried on the drying cylinder until the dryness is 92%, wrinkling is carried out ...

Embodiment 3

[0023] A kind of manufacture method of the colored dental paper scarf paper of crumpling, concrete steps are as follows: (1) the wood pulp waste paper long fiber that length is 2.8mm and the wood pulp waste paper short fiber that length is 1.0mm carry out disintegration , the weight ratio of long fibers and short fibers is 75:25; (2) The long fibers and short fibers after disintegration are mixed and beaten, and the degree of beating is controlled at 40°SR; (3) Polyamide epoxy is weighed per ton of paper Add 50kg of chloropropane resin wet strength agent, 2.0kg of dry strength agent, 18kg of neutral dye, 2kg of color fixing agent into the pulp, then add 0.3kg of bactericide, and carry out high temperature sterilization at 150°C; use cylinder or fourdrinier paper The machine is used for papermaking, the online concentration is 0.12%, and the vehicle speed is 85m / min. When the paper sheet is dried on the drying cylinder until the dryness is 94%, wrinkling is carried out on the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com