Method for preparing pesticide by using biomass hydrothermal carbonization liquid phase and preparing organic fertilizers by using solid phase

A technology of hydrothermal carbonization and solid-phase preparation, applied in botany equipment and methods, chemicals for biological control, biofuels, etc., can solve problems such as air pollution, achieve continuous, mild reaction conditions, and energy The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

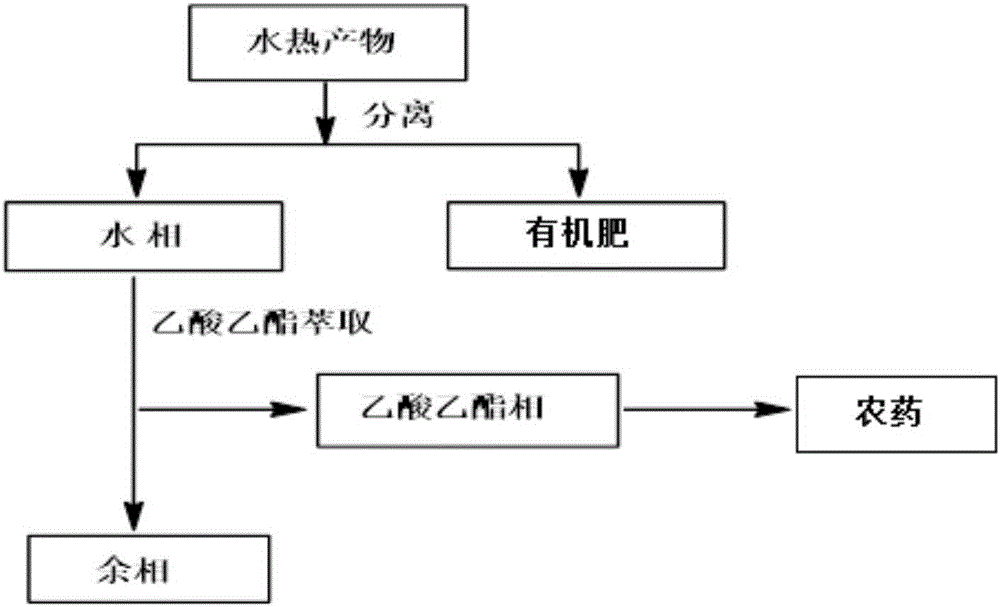

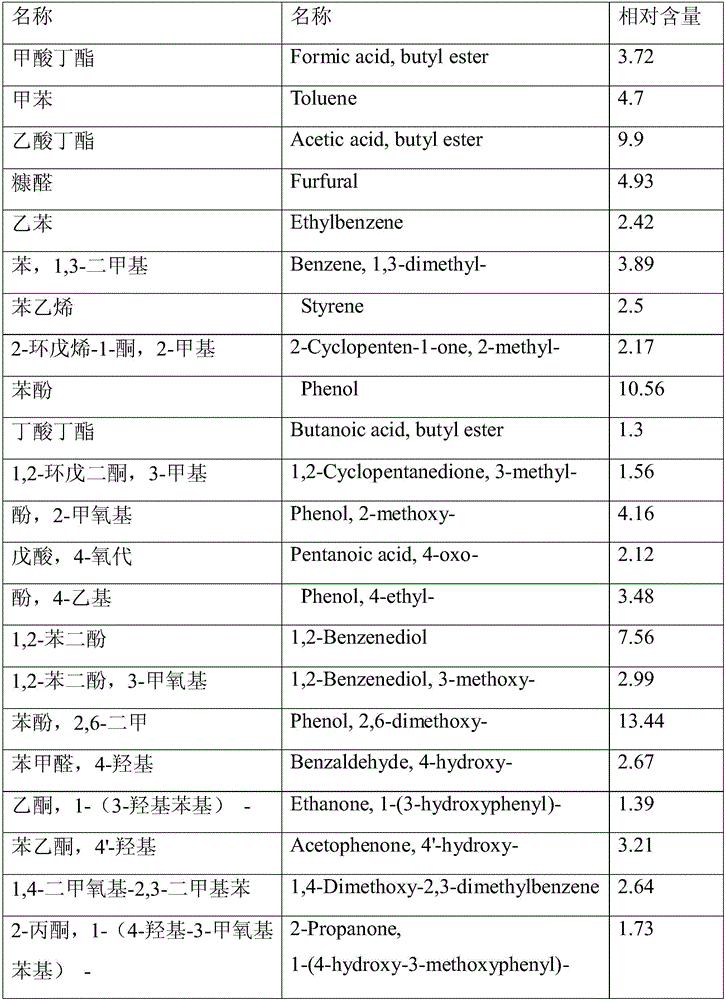

[0024] Mix 3 g of bagasse and 50 mL of water to obtain a biomass aqueous solution, then add it to a 150 mL high-pressure reactor, close the lid of the kettle, and replace the air in the reactor with nitrogen for 4 times. Then, turn on the condensing device and power supply of the reactor, set the reaction temperature to 225° C., and the stirring speed to 800 rpm. After raising the temperature to 225°C, keep the temperature constant for 5 hours. After the reaction was terminated, the reaction kettle was taken out and cooled to normal temperature, the gas was released, and the lid of the kettle was opened. The solid coke produced by the reaction and the water-phase product rich in stable components such as phenols are taken out, separated with a Buchner funnel, and the solid is dried to obtain organic fertilizer. The liquid-phase product is extracted with ethyl acetate and used to prepare pesticides.

Embodiment 2

[0026] Mix 3 g of bagasse and 50 mL of water to obtain a biomass aqueous solution, then add it to a 150 mL high-pressure reactor, close the lid of the kettle, and replace the air in the reactor with nitrogen for 4 times. Then, turn on the condensing device and power supply of the reactor, set the reaction temperature to 255° C., and the stirring speed to 800 rpm. After heating up to 255°C, keep the temperature constant for 5 hours. After the reaction was terminated, the reaction kettle was taken out and cooled to normal temperature, the gas was released, and the lid of the kettle was opened. The solid coke produced by the reaction and the water-phase product rich in stable components such as phenols are taken out, separated with a Buchner funnel, and the solid is dried to obtain organic fertilizer. The liquid-phase product is extracted with ethyl acetate and used to prepare pesticides.

Embodiment 3

[0028] Mix 3 g of bagasse and 50 mL of water to obtain a biomass aqueous solution, then add it to a 150 mL high-pressure reactor, close the lid of the kettle, and replace the air in the reactor with nitrogen for 4 times. Then, turn on the condensing device and the power supply of the reactor, set the reaction temperature to 265° C., and the stirring speed to 800 rpm. After raising the temperature to 265°C, keep the temperature constant for 5 hours. After the reaction was terminated, the reaction kettle was taken out and cooled to normal temperature, the gas was released, and the lid of the kettle was opened. The solid coke produced by the reaction and the water-phase product rich in stable components such as phenols are taken out, separated with a Buchner funnel, and the solid is dried to obtain organic fertilizer. The liquid-phase product is extracted with ethyl acetate and used to prepare pesticides.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com