Lysozyme hydrochloride toothpaste and preparation method thereof

A technology of lysozyme hydrochloride and toothpaste, which is applied in dentistry, pharmaceutical formulations, cosmetic preparations, etc., can solve the problems of affecting the safety of toothpaste, aggravating the disease, and imbalance of bacteria flora, so as to improve local circulation disorders, improve mucopolysaccharide metabolism, The effect of preventing wound infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0177] Embodiment 1: a kind of preparation method of lysozyme hydrochloride toothpaste

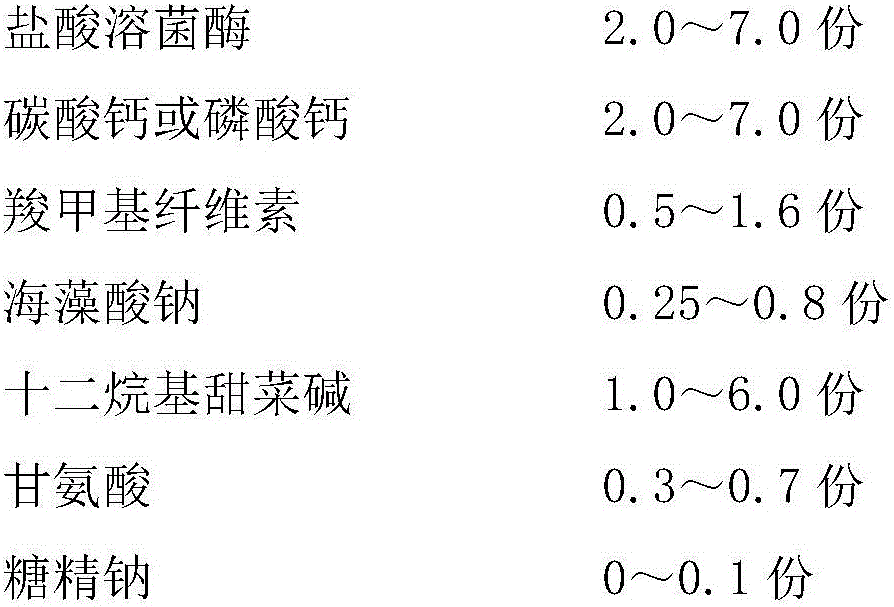

[0178] 1. A lysozyme hydrochloride toothpaste is made by parts by mass of the following raw materials:

[0179]

[0180] 2. The preparation method is as follows:

[0181] (1) Superfinely pulverize calcium carbonate, pass through a 400-mesh sieve, and obtain an average particle size of 15 to 21 μm by laser particle size measurement;

[0182] (2) adding deionized water to step (1) to prepare a mass ratio of calcium carbonate: deionized water=1:5, carry out colloid mill processing, and make a suspension solution for subsequent use;

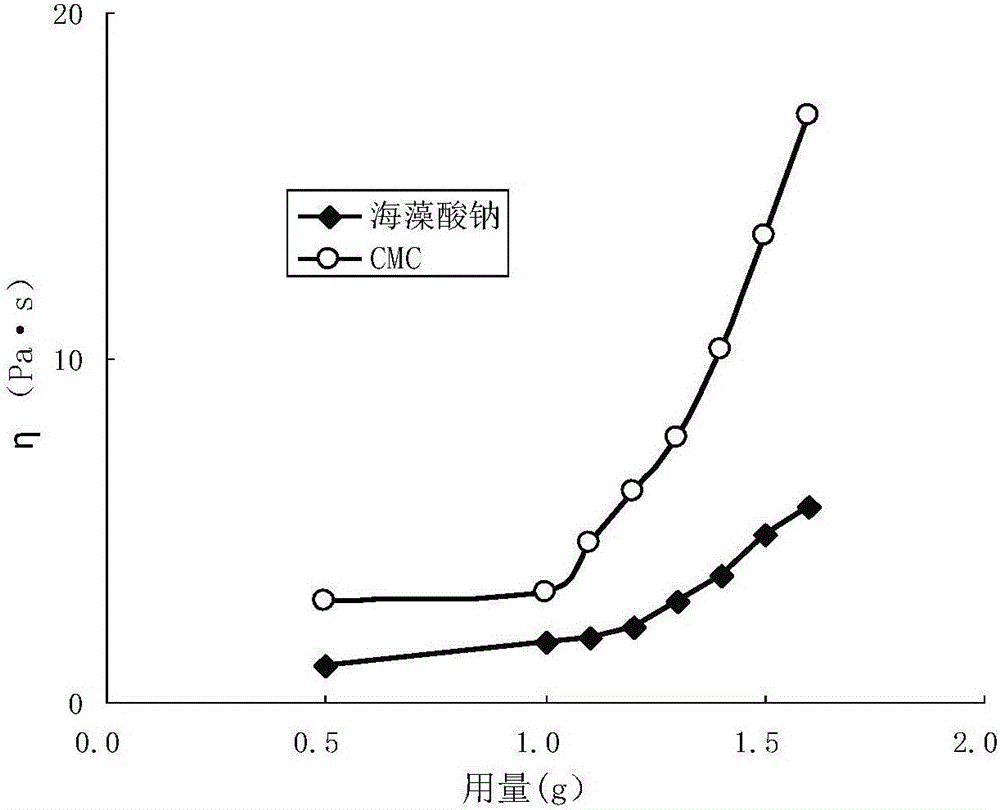

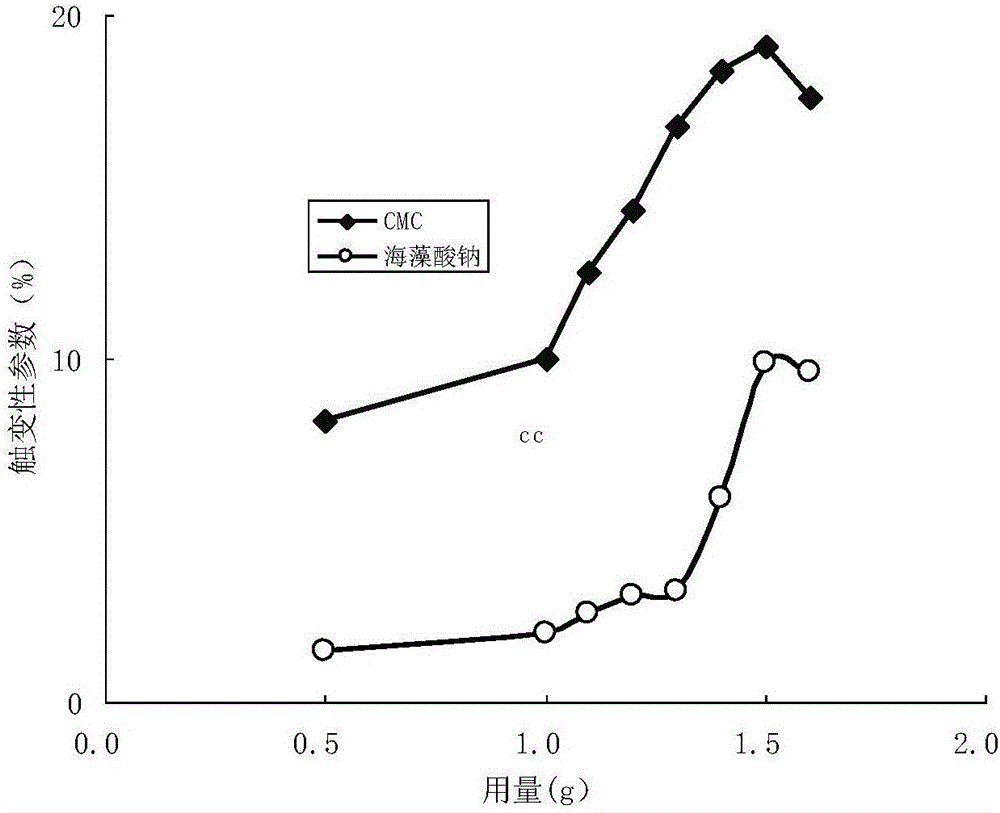

[0183] (3) Weigh each raw material according to the formula quantity, configure glycerin and sorbitol with deionized water to form a solution with a mass concentration of 15-25% for subsequent use; then add carboxymethyl cellulose, sodium alginate, sodium saccharin and essence , under the condition of 60-80°C, the rotating speed is 60-80r / min, and the time i...

Embodiment 2

[0186] Embodiment 2: a kind of preparation method of lysozyme hydrochloride toothpaste

[0187] 1. A lysozyme hydrochloride toothpaste is made by parts by mass of the following raw materials:

[0188]

[0189] 2. The preparation method is as follows:

[0190] (1) Superfinely pulverize calcium phosphate, pass through a 400-mesh sieve, and use laser particle size measurement to obtain an average particle size of 5-12 μm;

[0191] (2) adding deionized water to step (1) to prepare a mass ratio of calcium phosphate: deionized water=1:7, carry out colloid mill treatment, and make a suspension solution for subsequent use;

[0192] (3) Weigh each raw material according to the formula quantity, configure glycerin and sorbitol into a solution with a mass concentration of 20-30% with deionized water for subsequent use; then add carboxymethyl cellulose, sodium alginate, sodium saccharin and essence , under the condition of 60-70°C, the rotation speed is 60-75r / min, and the time is 30...

Embodiment 3

[0195] Embodiment 3: a kind of preparation method of lysozyme hydrochloride toothpaste

[0196] 1. A lysozyme hydrochloride toothpaste is made by parts by mass of the following raw materials:

[0197]

[0198] 2. The preparation method is as follows:

[0199] (1) Superfinely pulverize calcium carbonate, pass through a 400-mesh sieve, and obtain an average particle size of 15 to 21 μm by laser particle size measurement;

[0200] (2) adding deionized water to step (1) to prepare a mass ratio calcium carbonate: deionized water=1:8, carry out colloid mill treatment, make a suspension solution, and set aside;

[0201] (3) Weigh each raw material according to the formula quantity, configure glycerin and sorbitol into a solution with a mass concentration of 10-20% with deionized water for subsequent use; then add carboxymethyl cellulose, sodium alginate, sodium saccharin and essence , under the condition of 60-70°C, the rotation speed is 60-65r / min, and the time is 30-35 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com