Chitosan microsphere, and preparation method and application thereof

A technology of chitosan microspheres and chitosan, which is applied in the directions of application, pharmaceutical formulation, and medical preparations containing active ingredients, etc., to achieve the effects of promoting healing, good biocompatibility, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

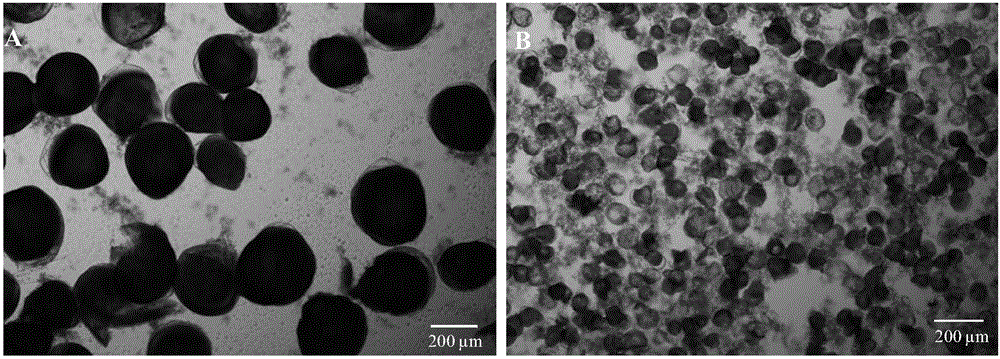

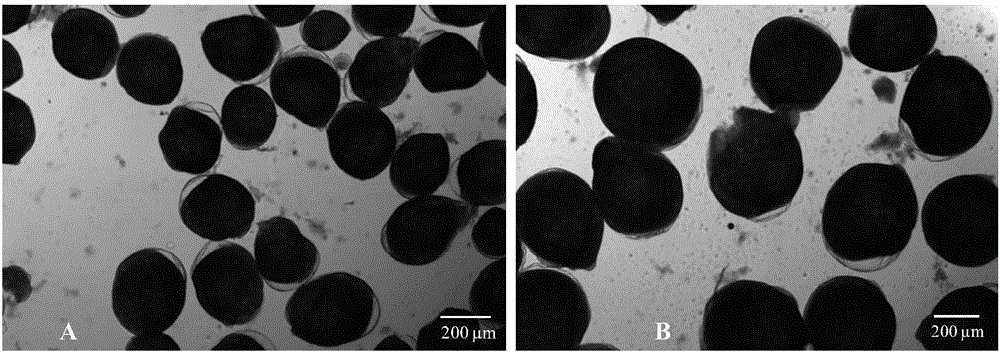

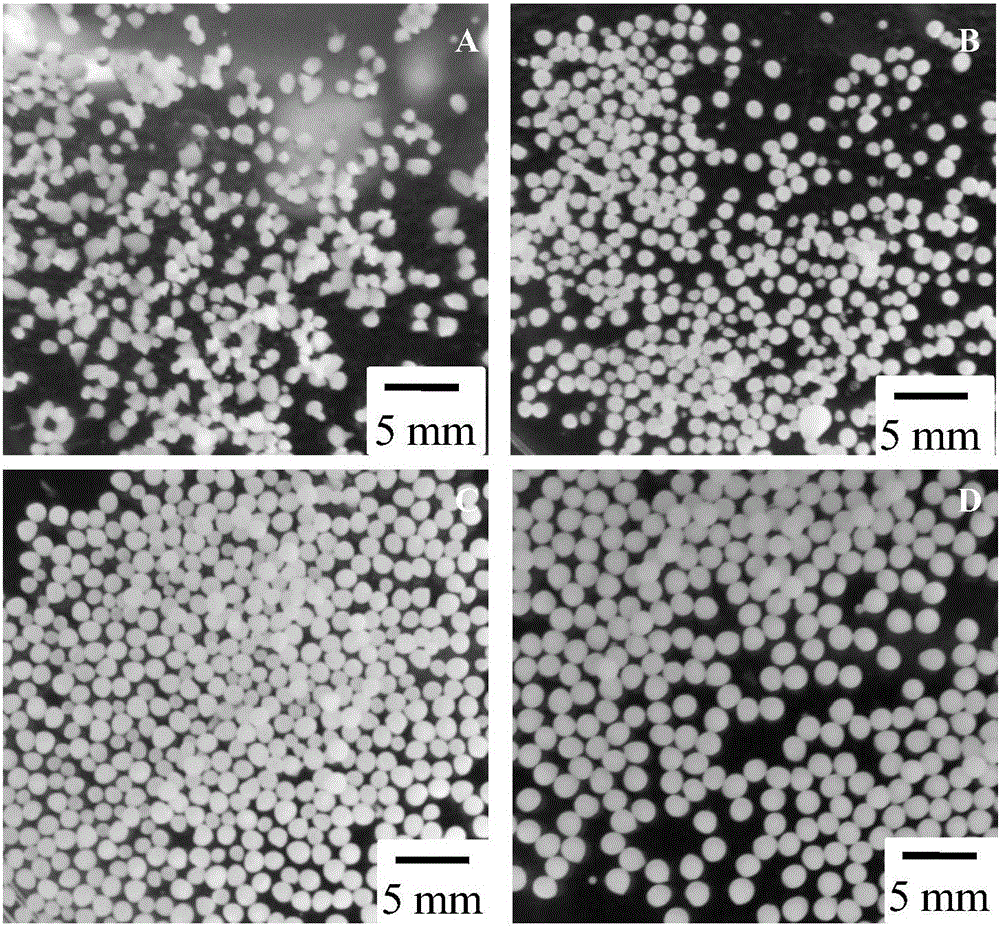

Image

Examples

preparation example Construction

[0042] The second aspect of the present invention provides a kind of preparation method of chitosan microsphere, comprises the following steps:

[0043] Prepare chitosan solution and hydrophilic polymer solution respectively, hydrophilic polymer comprises at least one in polyvinyl alcohol, gelatin, cellulose and polyethylene oxide, chitosan solution and hydrophilic polymer solution Mixing and mixing to obtain a mixed solution; in the mixed solution, the mass of chitosan and the mass of the hydrophilic polymer account for 25%-99% and 1%-75% of the total mass of the solute respectively;

[0044]The mixed solution is dripped into the negatively charged receiving solution by electrostatic spraying method, and left standing to obtain a suspension of microspheres. After the microspheres are separated and obtained, they are washed and dried to obtain chitosan microspheres, which consist of chitosan and hydrophilic polymer, in the chitosan microsphere, the mass percentage of chitosan ...

Embodiment 1

[0072] A preparation method of chitosan microspheres, comprising the following steps:

[0073] (1) Weigh 3 g of chitosan (CS) and dissolve it in 100 mL of dilute acetic acid to prepare a CS solution with a mass volume concentration of 3% (w / v), and store it at 4°C for future use. Weigh a certain amount of polyvinyl alcohol (PVA), place it in a constant temperature water bath at 70°C and stir until it is completely dissolved, then make a PVA solution with a mass volume concentration of 0.6% (w / v) with water, and store it at 4°C for later use. A certain amount of sodium polyphosphate (TPP) was weighed and dissolved in water to obtain a TPP aqueous solution with a mass volume concentration of 4.5% (w / v);

[0074] (2) get a certain amount of above-mentioned chitosan solution and polyvinyl alcohol solution, fully mix, the mass volume concentration of both chitosan and PVA in the mixed solution is 1.8%, wherein, the mass ratio of chitosan and PVA is 5:1. And set the propulsion spe...

Embodiment 2

[0077] A preparation method of chitosan microspheres, comprising the following steps:

[0078] (1) Weigh 3 g of chitosan (CS) and dissolve it in 100 mL of dilute acetic acid to prepare a CS solution with a mass volume concentration of 3% (w / v), and store it at 4°C for future use. Weigh a certain amount of polyvinyl alcohol (PVA), place it in a constant temperature water bath at 70°C and stir until it is completely dissolved, then make a PVA solution with a mass volume concentration of 0.6% (w / v) with water, and store it at 4°C for later use. A certain amount of sodium polyphosphate (TPP) was weighed and dissolved in water to obtain a TPP aqueous solution with a mass volume concentration of 4.5% (w / v).

[0079] (2) get a certain amount of above-mentioned chitosan solution and polyvinyl alcohol solution, fully mix, the mass volume concentration of both chitosan and PVA in the mixed solution is 1.8%, wherein, the mass ratio of chitosan and PVA It is 5:1. Set the receiving dista...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com