Preparation method of low temperature resistance polysaccharide microbial flocculant and application thereof

A microbial flocculant and low-temperature-resistant technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., to achieve the effect of saving production costs and good flocculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

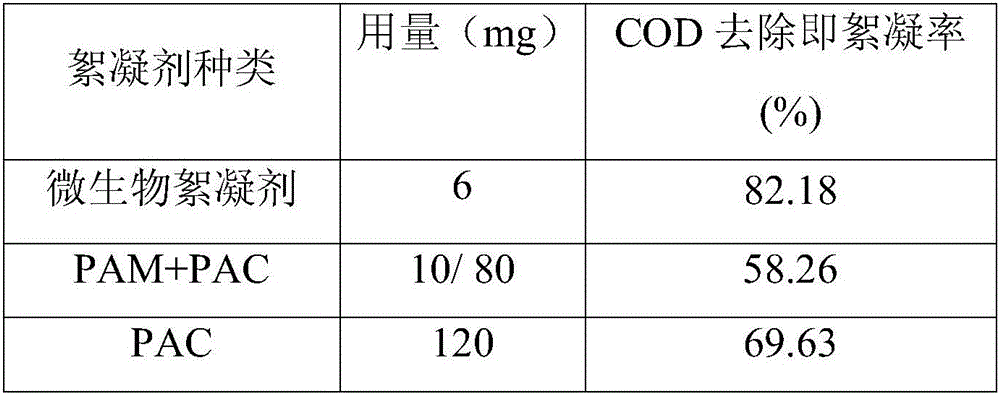

Image

Examples

Embodiment 1

[0022] The preparation method of this microbial flocculant, its step comprises:

[0023] (1) Take the Klebsiella oxytoca GS-4-08 strain cultured in the laboratory and grow aerobically at 35°C for 12 hours;

[0024] The components of the strain growth medium are: glucose 5.92g / L, KH 2 PO 4 2g / L, Na 2 HPO 4 12H 2 O 10.3g / L, NaCl 0.05g / L, MgSO 4 ·7H 2 O 0.5g / L, FeSO 4 ·7H 2 O 0.01g / L, urea 2.13g / L, adjust the pH value to be 7; cultivate a large amount of Klebsiella oxytoca GS-4-08 bacterial classification that obtains, and the preservation number of this bacterial classification is CGMCCNo.5237;

[0025] (2) Add the culture solution when the aerobic growth reaches the end of exponential growth into the mixed waste water with a treatment volume of 1 liter according to the inoculum rate of 10%, and carry out aeration treatment;

[0026] Respectively adjust the ratio of sucrose factory wastewater and nitrile wastewater in the mixed wastewater to be: 1:1, 3:1, 5:1, 10:1, 20...

Embodiment 2

[0033] The application of the microbial flocculant in the flocculation treatment of soybean product wastewater comprises the following steps:

[0034] To the COD concentration is 12000mg / L bean product former waste water (50mL), add microbial flocculant 0.3mg among the embodiment 1, leave standstill 10min after stirring 30s rapidly with the stirring speed of 240rpm, measure the COD concentration of waste water supernatant, The treatment water temperatures are 4, 25, 35, 45, 55, 65°C respectively. The results of COD removal rate are shown in Table 2. As can be seen from Table 2, when the present invention is treated at room temperature, the COD removal efficiency of the bio-flocculant prepared by the present invention is higher to the bean product wastewater, and the COD removal efficiency of the bio-flocculant of the present invention is processed when the temperature is 4 It can also reach 81.16, which has high efficiency, which shows that the biological flocculant can treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com