Preparation method of a friction-reducing and wear-resistant polymer-based composite material

A composite material and polymer technology, which is applied in the field of preparation of friction-reducing and wear-resistant polymer-based composite materials, can solve the problems such as the lack of micro-nano hybrid materials, improve the tribological properties of polyimide, and achieve a novel preparation method. , The effect of improving tribological properties and low friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Add 75mL of ethanol, 3mL of distilled water, and 28mL of ammonia water into the beaker in sequence, stir for 2 hours with magnetic force, and stir until uniform, wherein the mass fraction of ammonia water is 25%-28%.

[0025] (2) Add 2.5 mL of tetraethyl orthosilicate (TEOS) dropwise to (1), and ensure magnetic stirring during the dropping process. After the dropwise addition, seal the mouth of the cup and continue to stir for 12 hours. The mouth of the beaker is sealed to prevent volatilization of volatile substances.

[0026] (3) After the reaction is completed, centrifuge, wash three times with deionized water, wash three times with ethanol, and dry in an oven at 80°C to obtain nano-silica (SiO 2 ).

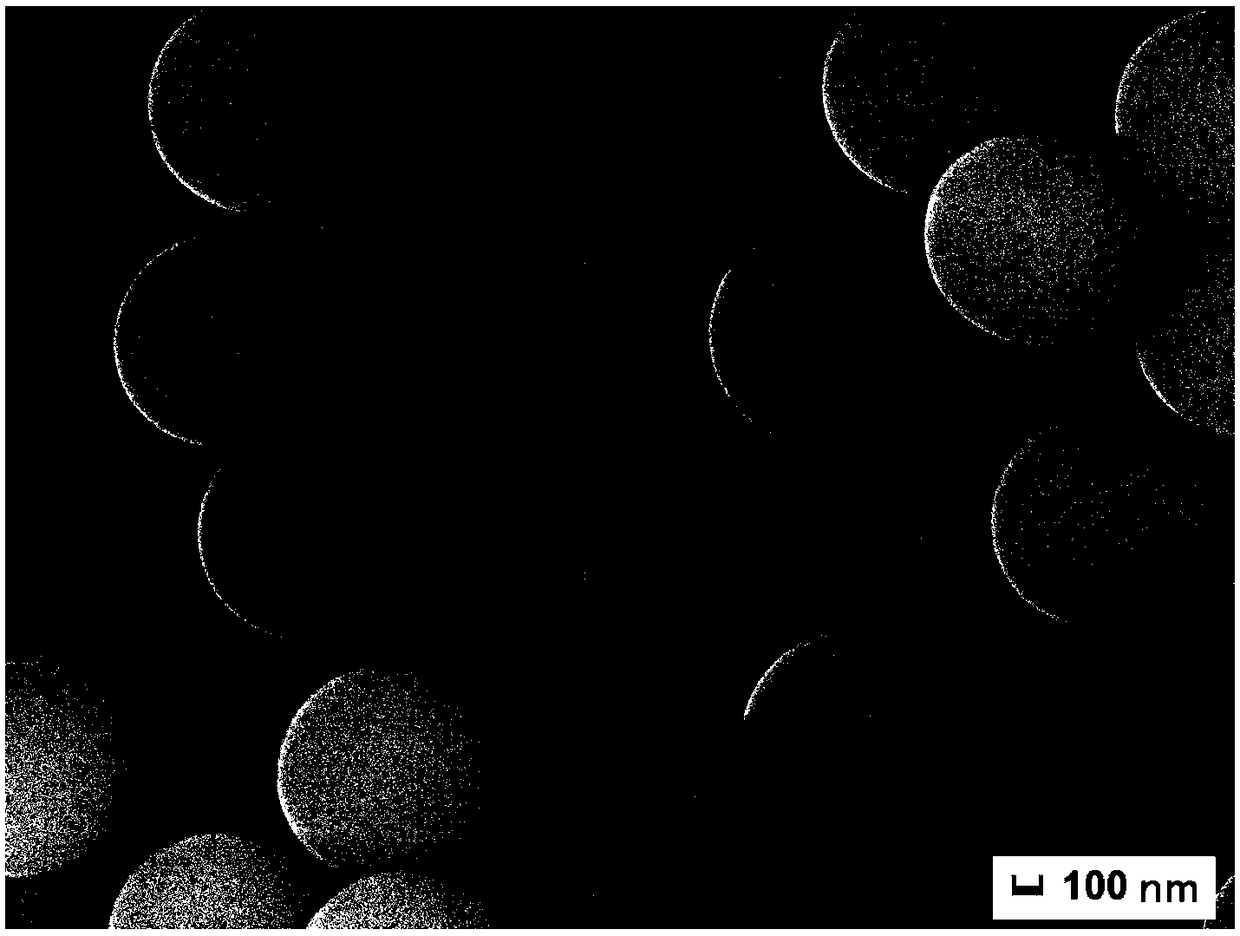

[0027] figure 1 is the prepared nano-SiO 2 The scanning electron microscope topography, it can be seen from the figure that SiO 2 presents a spherical structure.

Embodiment 2

[0029] (1) Add 75mL of absolute ethanol, 3mL of distilled water, 82mL of ammonia, and 5g of carbon fiber (CF) into a beaker in sequence, and stir until uniform, wherein the mass fraction of ammonia is 25% to 28%.

[0030] (2) Add 7 mL of tetraethyl orthosilicate (TEOS) dropwise to (1), and ensure magnetic stirring during the dropping process. After the dropwise addition, seal the mouth of the cup and continue to stir for 4 hours. The mouth of the beaker is sealed to prevent volatilization of volatile substances.

[0031] (3) After the reaction is completed, centrifuge, wash with deionized water three times, wash with ethanol three times, and dry in an oven at 80°C to obtain the carbon fiber-silica hybrid material CF-SiO 2 .

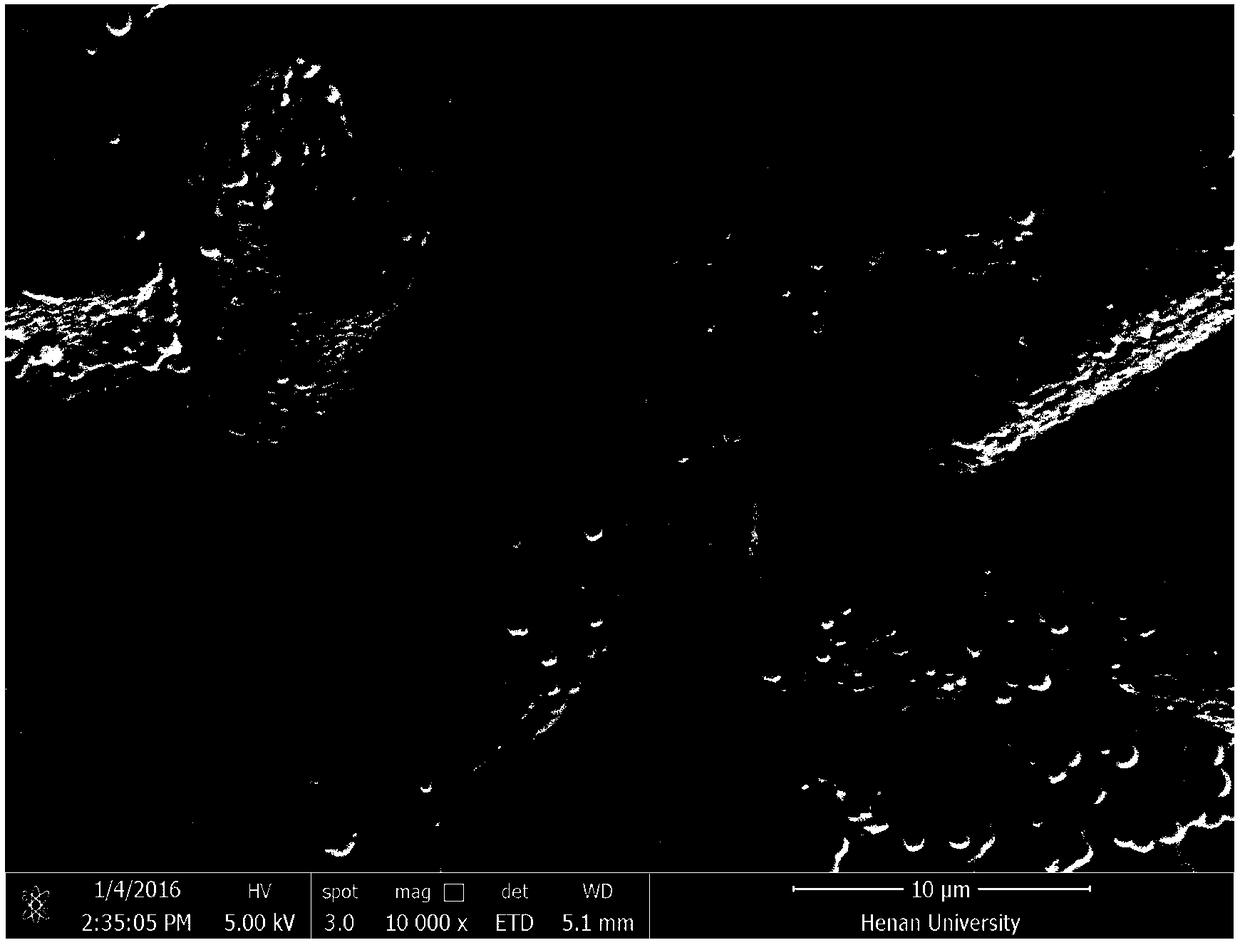

[0032] figure 2 is the prepared CF-SiO 2 The scanning electron microscope topography of the hybrid material, it can be seen from the figure that nano-SiO is synthesized in situ on the surface of the carbon fiber 2 , and the silica particles uniformly...

Embodiment 3

[0034] (1) Weigh pyromellitic anhydride (PMDA) and 4,4'-diaminodiphenyl ether (ODA), first add ODA to dimethylacetamide solvent (DMAC), and dissolve it completely under stirring . The amount ratio of PMDA, ODA and DMAC solvent is 0.025mol: 0.025mol: 70mL. Secondly, add pyromellitic anhydride (PMDA) three times under stirring, with an interval of 15 to 20 minutes between each two times. The process is carried out in an ice-water bath, and the reaction temperature is kept at about 4°C, so continue to stir under normal pressure, react for 8 hours, and finally obtain a light yellow transparent solution, which is a polyimide precursor solution, and store it below 0°C until use.

[0035] (2) Operation A: Take 6.0g of polyimide precursor solution, flow it on the glass to form a film by casting method, then put it into an oven, keep it at 60°C for 6 hours, and then gradually increase the temperature from 60°C to 80°C respectively , 100°C, 120°C, 160°C, 180°C, 200°C, and keep warm f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com