Preparation method of photo-anode, photo-anode and dye-sensitized solar cell

A photoanode and conductive glass technology, applied in the field of solar cell manufacturing, can solve the problems of poor electron transmission characteristics, light scattering ability, and low specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

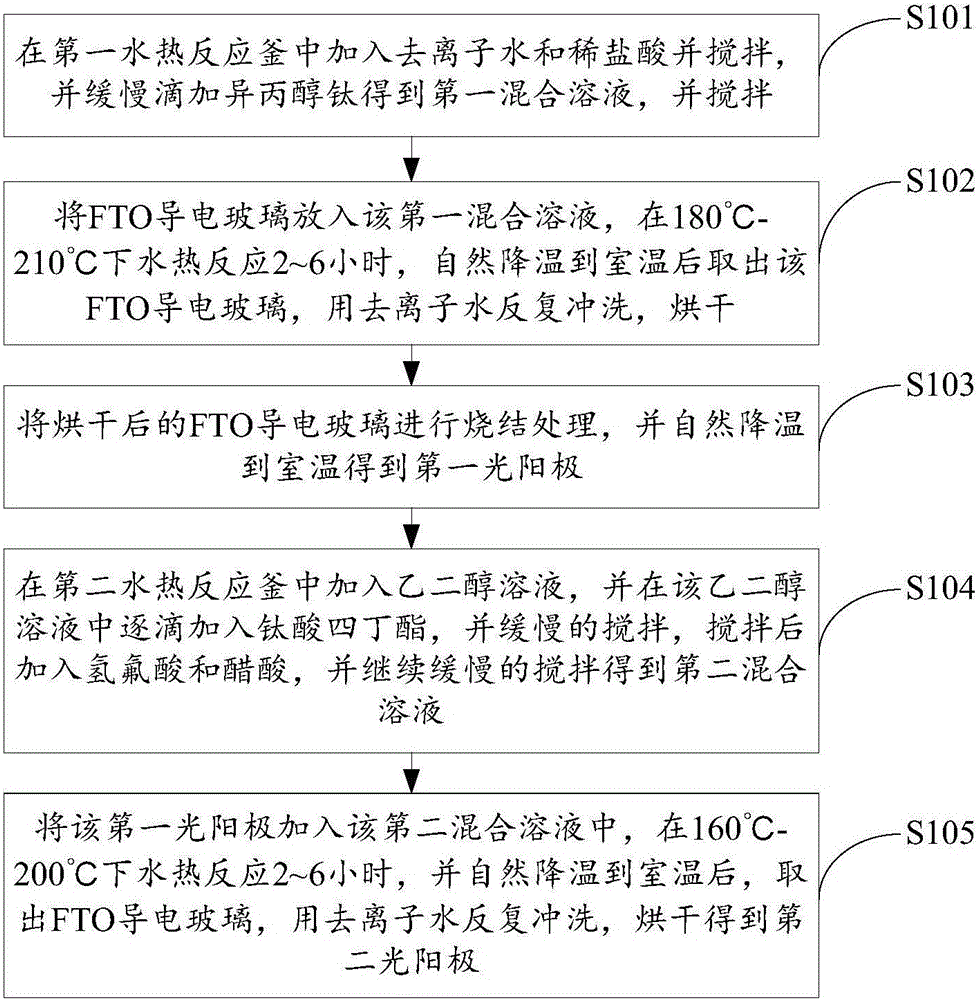

[0019] figure 1 A kind of preparation method of photoanode provided for the embodiment of the present invention, such as figure 1 shown, including:

[0020] S101. Add deionized water and dilute hydrochloric acid into the first hydrothermal reaction kettle and stir, and slowly add titanium isopropoxide dropwise to obtain a first mixed solution, and stir.

[0021] Wherein, the volume of the deionized water is 30 mL, the volume of the dilute hydrochloric acid is 30 mL, the concentration of the dilute hydrochloric acid is 36.5%-38%, and the volume of the titanium isopropoxide is 0.5 mL-0.9 mL.

[0022] S102. Put the FTO conductive glass into the first mixed solution, conduct a hydrothermal reaction at 180°C-210°C for 2-6 hours, take out the FTO conductive glass after cooling down to room temperature naturally, rinse it repeatedly with deionized water, and dry it.

[0023] S103 , sintering the dried FTO conductive glass, and naturally cooling down to room temperature to obtain a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com