LED and manufacturing method therefor

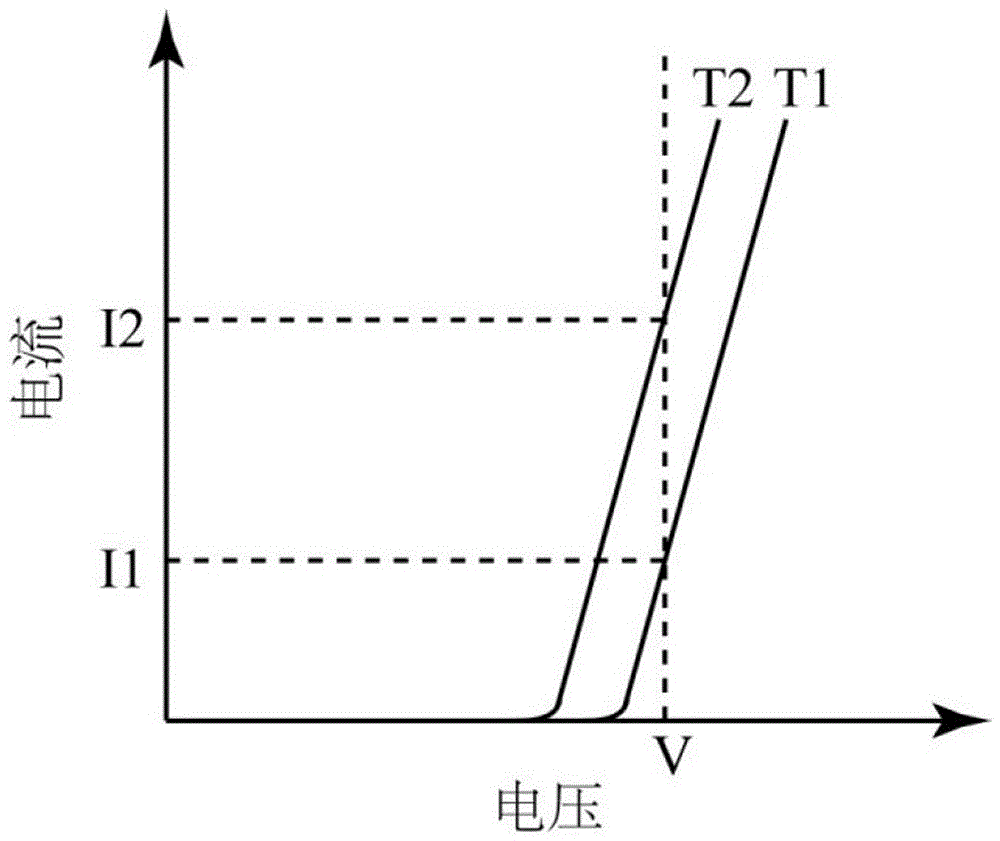

A manufacturing method and epitaxial layer technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as driving current increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

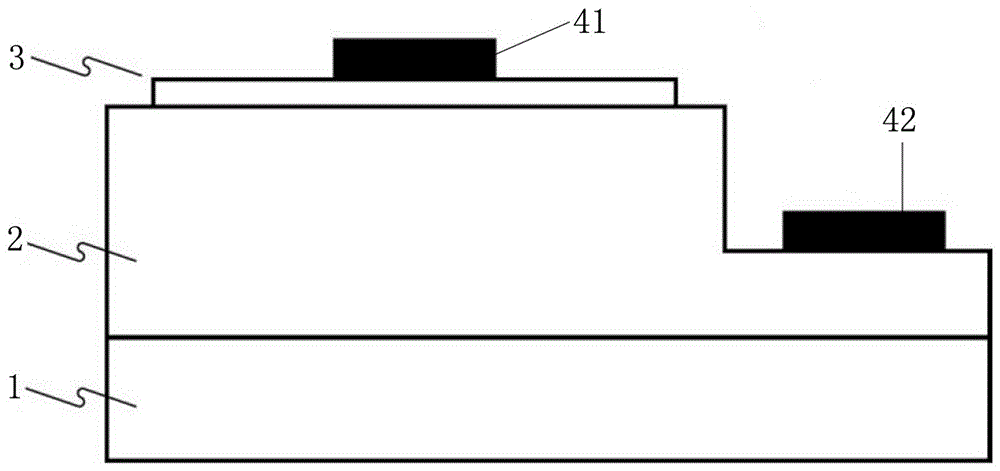

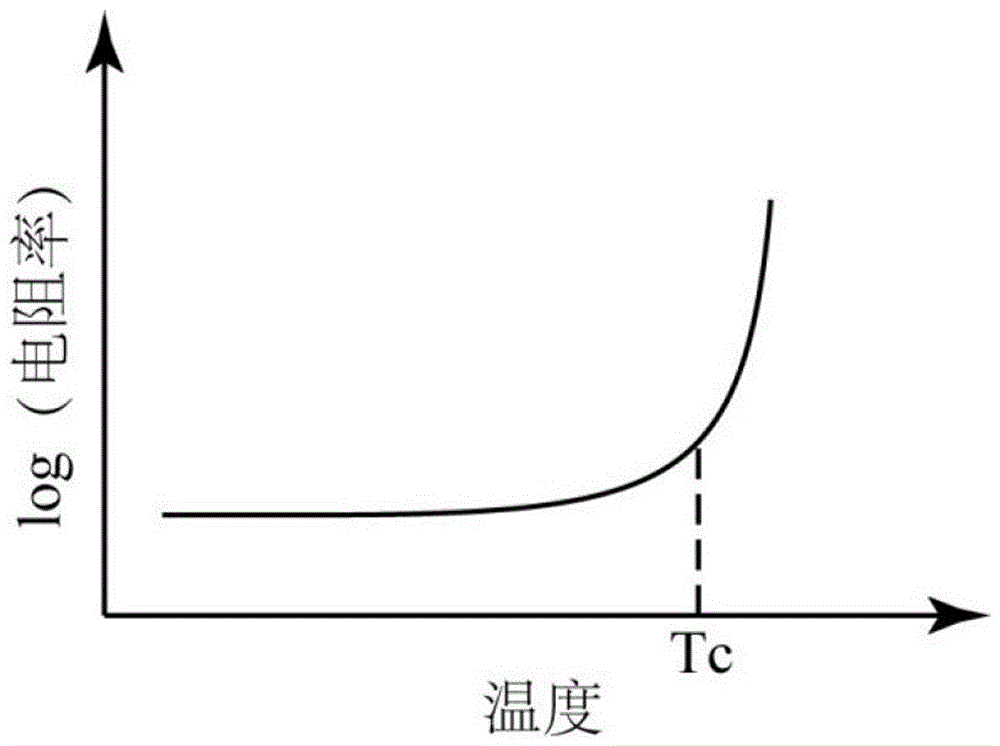

[0047] Use epoxy resin as the polymer matrix material, indium tin oxide (ITO) as the conductive filler, and mix uniformly according to the volume ratio of 1:0.4 to make the conductive polymer composite material. The conductive polymer composite material is evenly coated on the epitaxial layer by a spin coating method. Then the epitaxial wafer was placed in an oven and cured at 110° C. for 10 minutes. After standard photolithography and etching processes, a transparent conductive layer with variable resistivity is formed with a thickness of 1200A. After standard photolithography, evaporation, and alloying processes, the metal electrodes are fabricated. Finally, the substrate is ground and polished, and the epitaxial wafer is cut into an area of about 120,000 um 2 stand-alone light-emitting diode devices. The Curie temperature Tc of the variable resistivity transparent conductive layer in this embodiment is about 100° C., its resistivity at room temperature is about 50 Ωcm,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com