Three-dimensional graphitized carbon material rich in continuous mesoporous structure and preparation method thereof

A mesoporous structure and graphitized carbon technology, applied in the field of carbon materials, can solve the problems of difficult removal of templates, increased costs, and hidden dangers of environmental pollution caused by organic surfactants, and achieve the effect of mature preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

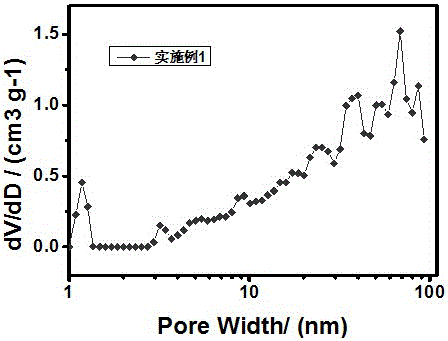

Embodiment 1

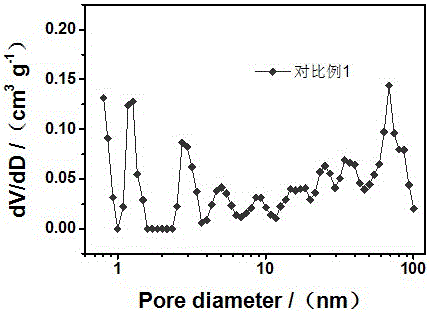

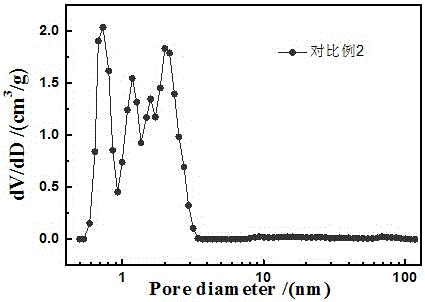

[0039] Take 10 g of pretreated macroporous weakly acidic acrylic cation exchange resin and add it to 100 mL of 0.05 mol L -1 Nickel acetate aqueous solution, magnetically stirred for 6 h, and then the exchanged ion exchange resin was washed with deionized water, filtered, and dried. Take 10 g of the dried exchange resin, add to 100 mL dissolved in 5 g Ca(OH) 2 Ca(OH) 2 / ethanol mixed solution at 80 o C, stir and dry until paste, then turn to 70 o C in an oven dried and crushed. The pulverized product was placed in a tube furnace, under nitrogen atmosphere, with 2 o C min -1 The heating rate rises from room temperature to 950 o C, and kept at this temperature for 2h. The resulting product was treated with 2 mol L -1 Hydrochloric acid treatment, wash and filter with deionized water until the pH of the filtrate is neutral, then at 80 o Place it under C for 12 h and dry it to obtain the sample of Example 1. BET test result shows, the specific surface area of embodimen...

Embodiment 2

[0041] Take 10 g of pretreated macroporous weakly acidic acrylic cation exchange resin and add it to 100 mL of 0.05 mol L -1 Nickel acetate aqueous solution, magnetically stirred for 6 h, and then the exchanged ion exchange resin was washed with deionized water, filtered, and dried. Take 10 g of the dried exchange resin, add to 100 mL dissolved in 10 g Ca(OH) 2 Ca(OH) 2 / ethanol mixed solution at 80 o C, stir and dry until paste, then turn to 70 o C in an oven dried and crushed. The pulverized product was placed in a tube furnace, under nitrogen atmosphere, with 2 o C min -1 The heating rate rises from room temperature to 950 o C, and kept at this temperature for 2 h. The resulting product was treated with 2 mol L -1 Hydrochloric acid treatment, wash and filter with deionized water until the pH of the filtrate is neutral, then at 80 o Place it under C for 12 h and dry it to obtain the sample of Example 2. BET test result shows, the specific surface area of embodim...

Embodiment 3

[0043] Take 10 g of pretreated D113 resin intermediate white ball, add to 100 mL 0.05 mol L -1 Cobalt chloride aqueous solution, at 80 o C, stir and dry until paste, then turn to 70 o C in an oven dried and crushed. Take 10 g of the dried resin, add to 100 mL dissolved in 10 g Ca(OH) 2 Ca(OH) 2 / ethanol mixed solution at 80 o C, stir and dry until paste, then turn to 70 o C in an oven dried and crushed. The pulverized product was placed in a tube furnace, under nitrogen atmosphere, with 2 o C min -1 The heating rate rises from room temperature to 950 o C, and kept at this temperature for 2 h. The resulting product was treated with 2 molL -1 Hydrochloric acid treatment, wash and filter with deionized water until the pH of the filtrate is neutral, then at 80 o Place it under C for 12 h and dry it to obtain the sample of Example 3. BET test result shows, the specific surface area of embodiment 3 sample is 400 m 2 g -1 , with a total pore volume of 0.62 cm 3 g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com