Preparation method and equipment of gradient wetted surface for achieving self-driving of liquid drops

A gradient wetting, self-driving technology, applied in the photoengraving process, optomechanical equipment, microlithography exposure equipment and other directions of the pattern surface, can solve the problem that the gradient wetting surface cannot be industrialized, etc. Simple equipment and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

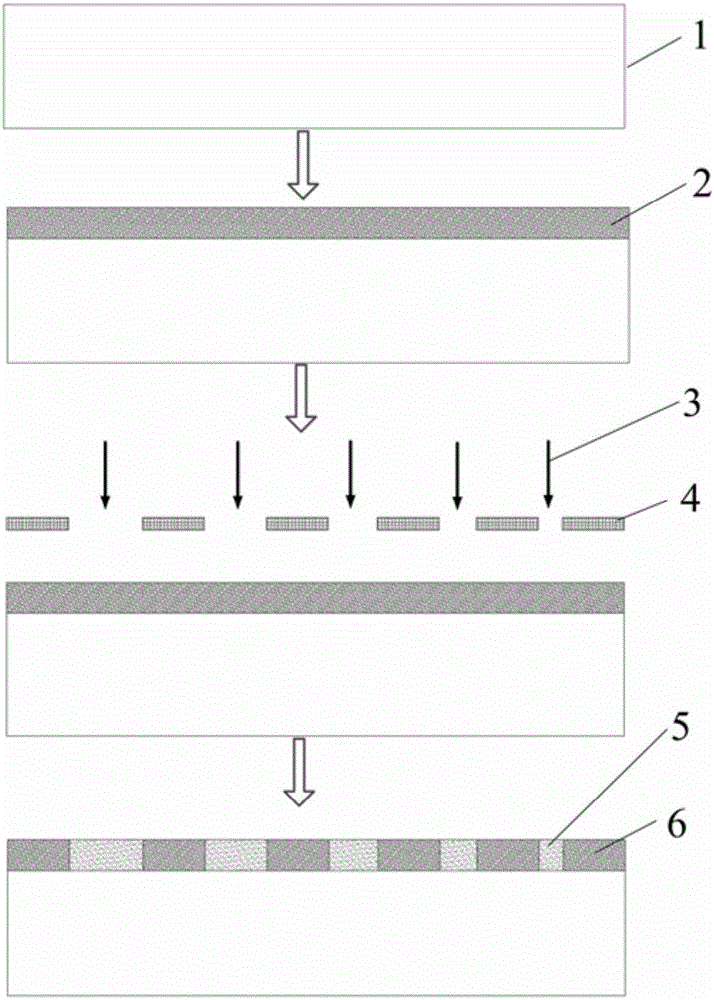

[0029] Embodiment 1 The preparation method of the self-driven gradient wetting surface of droplets according to the present invention comprises the following steps:

[0030] 1) Preparation of superhydrophobic titanium dioxide coating solution: mix 0.1g of titanium dioxide powder with a particle size of 25nm and 10mL of absolute ethanol, and then ultrasonicate at 100Hz for 15min to form a 0.01g / mL titanium dioxide suspension, then add 0.2mL of ten Octyltrimethoxysilane, continue to mix under 100Hz ultrasonic for 10min, then react at room temperature for 12h to obtain a superhydrophobic titanium dioxide coating solution for coating, that is, a superhydrophobic titanium dioxide coating, wherein the octadecane The volume ratio of trimethoxysilane to titanium dioxide suspension is 0.02:1;

[0031] 2) Preparation of a substrate with a superhydrophobic surface: use a spin coater to spin-coat the superhydrophobic titanium dioxide coating solution onto the cleaned substrate surface fiv...

Embodiment 2

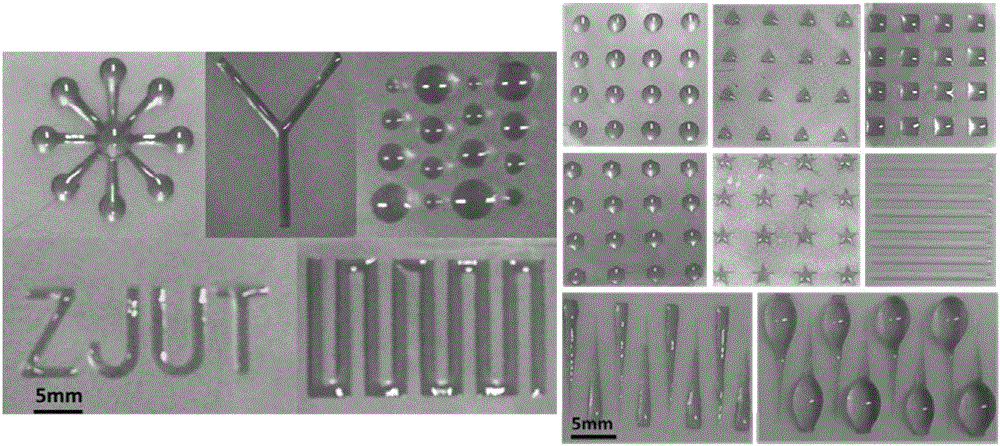

[0036] Embodiment 2 The device constructed according to the preparation method of claim 1, comprising a substrate 1 and a hydrophilic-hydrophobic layer 2 coated on the surface of the substrate, the hydrophilic-hydrophobic layer 2 is divided into seven regions, and the regions Arrange from the sample feeding end of the matrix to the detection end of the matrix along the axial direction of the matrix, and the same area is composed of several superhydrophilic patterns, while from the sample loading end of the matrix to the detection end of the matrix along the axial direction of the matrix, the hydrophilicity of the adjacent area The number of water patterns increases, that is, the distance between hydrophilic patterns in adjacent regions decreases, and the proportion of hydrophilic regions on the corresponding substrate increases gradually. Gradient wetting surface, the part corresponding to the hydrophilic pattern is the superhydrophilic region 5 , and the part outside the hydro...

Embodiment 3

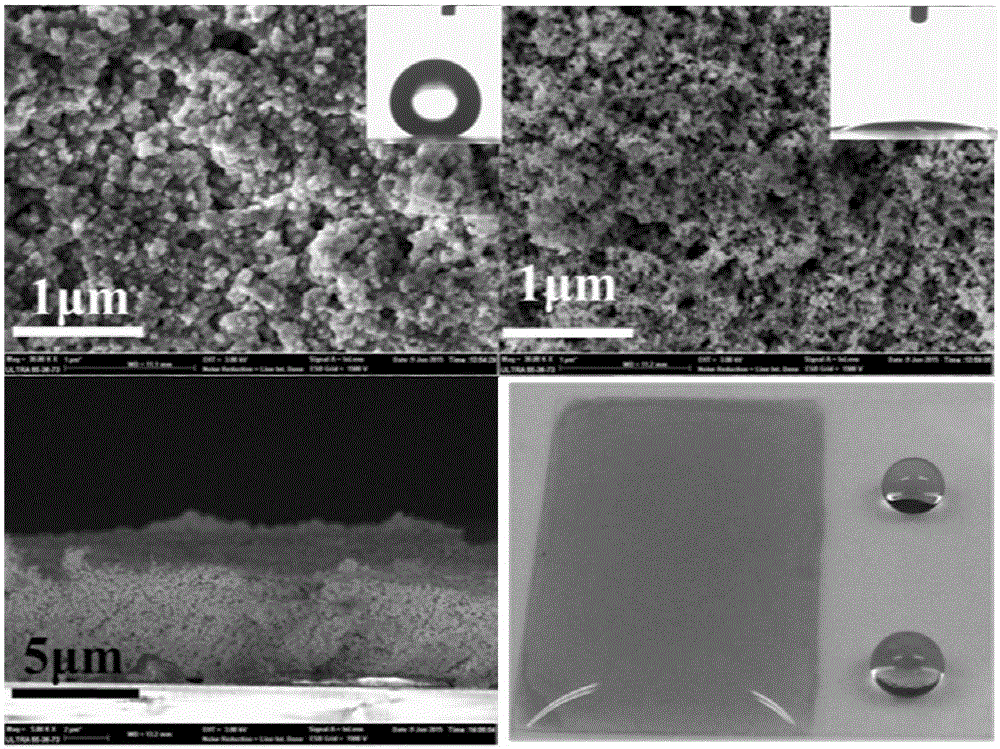

[0039]Embodiment 3: The difference between this embodiment and Example 1 is: the substrate is a glass substrate, and the preparation method of the glass substrate with a super-hydrophobic layer is: each ultrasonic cleaning of the glass sheet in acetone, ethanol, and deionized water for 10min, Then set the rotation speed of the spin coater to 1000 rad / min, spin coat five times, and spin coat the suspension on the cleaned glass substrate by five drops each time, and finally treat it in an oven at 120 ° C for 1 h to obtain The substrate of the hydrophobic layer, such as figure 2 The upper left is the SEM image of the superhydrophobic surface, and the illustration in the upper right corner is a picture of the water contact angle of the surface, the contact angle is 152.5°, figure 2 The lower left is a cross-sectional view of the super-hydrophobic layer. It can be seen that the thickness of the coating is about 5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com