Preparation method and quality control method of mulberry leaf extract

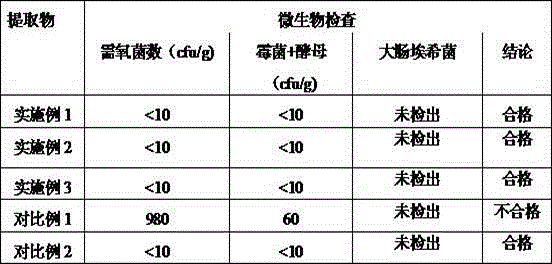

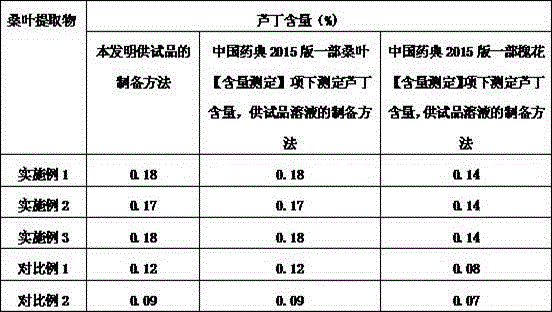

A quality control method, the technology of mulberry leaf extract, which is applied in the field of preparation of mulberry leaf extract, can solve the problems of increased probability of microbial failure, cumbersome operation, and decreased rutin content, so as to avoid the loss of rutin content and repeatability. Good, good extraction and retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: the preparation of mulberry leaf extract

[0027] (1) Shred mulberry leaves, add water to decoct and extract twice, add 13 times the weight of water for the first time, boil, decoct and extract for 1.5 hours, add 8 times the weight of water for the second time, boil, decoct and extract for 1 hour , combined the two decocted filtrates, filtered through a 350-mesh sieve to obtain the initial filtrate;

[0028] (2) Take the primary filtrate and pass it through a microporous membrane with a pore size of 0.02 microns to obtain a fine filtrate; the control parameters of the microporous membrane are: P1≤1.8MPa, P2≤1.75MPa, filtrate temperature≤45°C, pressure difference control At 0.05~0.1MPa;

[0029] (3) Concentrate the refined filtrate through a reverse osmosis membrane with a pore size of 0.0005 microns to a solid content rate of 16% to obtain a concentrated initial solution; the control parameters of the reverse osmosis membrane are: P1≤1.8MPa, P2≤1.75MPa, f...

Embodiment 2

[0031] Embodiment 2: the preparation of mulberry leaf extract

[0032] (1) Shred mulberry leaves, add water to decoct and extract twice, add 12 times the weight of water for the first time, boil, decoct and extract for 1.0 hour, add 9 times the weight of water for the second time, boil, decoct and extract for 1.5 hours , combined the two decocted filtrates, filtered through a 350-mesh sieve to obtain the initial filtrate;

[0033] (2) Take the primary filtrate and pass it through a microporous membrane with a pore size of 0.01 microns to obtain a refined filtrate; the control parameters of the microporous membrane are: P1≤1.8MPa, P2≤1.75MPa, filtrate temperature≤45°C, pressure difference control At 0.05~0.1MPa;

[0034] (3) Concentrate the refined filtrate through a reverse osmosis membrane with a pore size of 0.001 microns to a solid content of 15%, and obtain the initial concentrated liquid; the control parameters of the reverse osmosis membrane are: P1≤1.8MPa, P2≤1.75MPa, ...

Embodiment 3

[0036] Embodiment 3: the preparation of mulberry leaf extract

[0037] (1) Shred mulberry leaves, add water to decoct and extract twice, add 10 times the weight of water for the first time, boil, decoct and extract for 1.2 hours, add 10 times the weight of water for the second time, boil, decoct and extract for 1.2 hours , combined the two decocted filtrates, filtered through a 350-mesh sieve to obtain the initial filtrate;

[0038] (2) Take the primary filtrate and pass it through a microporous membrane with a pore size of 0.02 microns to obtain a fine filtrate; the control parameters of the microporous membrane are: P1≤1.8MPa, P2≤1.75MPa, filtrate temperature≤45°C, pressure difference control At 0.05~0.1MPa;

[0039] (3) Concentrate the refined filtrate through a reverse osmosis membrane with a pore size of 0.0001 micron to a solid content rate of 18% to obtain the initial concentrated liquid; the control parameters of the reverse osmosis membrane are: P1≤1.8MPa, P2≤1.75MPa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com