Aluminum oxide microwave dielectric ceramic and preparation method thereof

A technology of microwave dielectric ceramics and alumina, which is applied in the field of inorganic non-metallic functional materials, can solve the problems of inability to obtain high microwave dielectric properties and high withstand voltage properties of alumina microwave dielectric ceramics, and achieve improved density, high microwave Dielectric properties, effect of reducing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

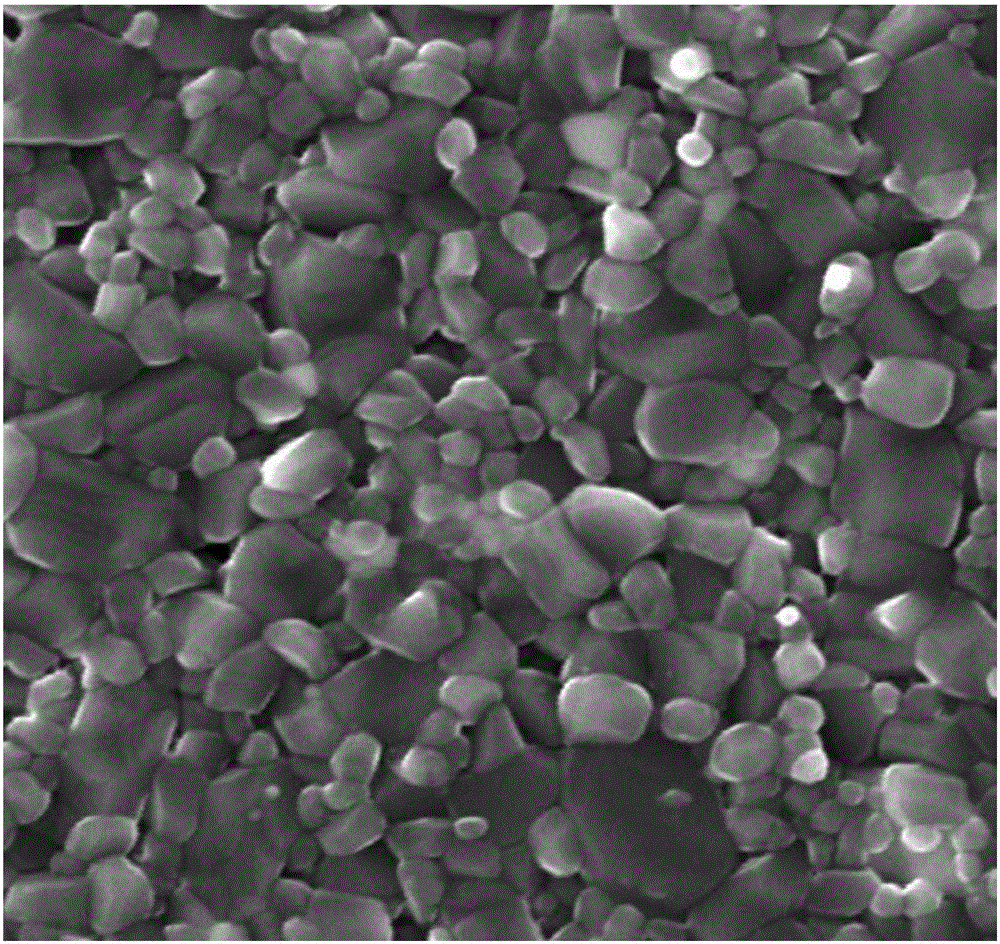

[0026] The method for preparing the above-mentioned alumina microwave dielectric ceramics provided in the embodiments of the present invention includes such process steps as preparation of CMS mixture, mixing and ball milling, granulation, tableting, debinding and sintering, etc. By adding CMS mixture as a sintering aid, the ceramic The temperature is lowered below 1650°C to increase the density of ceramics, and the combination of CMS mixture and Y 2 o 3 with ZrO 2 , reducing the influence of the CMS mixture on the deterioration of the microwave dielectric properties of the ceramics, improving the density of the alumina ceramics to a large extent, reducing the porosity, and improving the microwave dielectric properties of the alumina microwave dielectric ceramics; at the same time, the alumina ceramics ZrO 2 , can inhibit the excessive growth of grains, refine the grains, and improve the density of ceramics. But due to ZrO 2 At a high temperature of 1200°C, a structural ph...

Embodiment 1~9

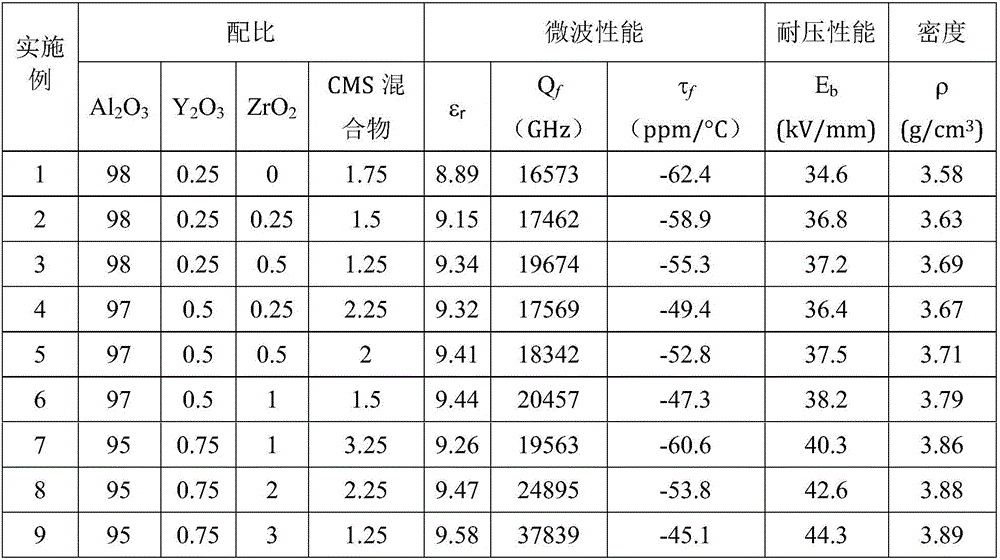

[0033] Select Al with a particle size of 1-2 μm 2 o 3 The powder is a raw material; the mass percentage is 69.5% CaCO 3 , 12.9% by mass of MgO, 17.6% by mass of SiO 2 After ball milling and mixing, the mixture was calcined at 900 °C for 2 h to obtain the CMS mixture powder; the Al 2 o 3 The mass percentage of the powder is fixed at 98%, and the Y 2 o 3 The mass percentage of the powder is fixed at 0.25%, and the rest is ZrO 2 and CMS mixture, when ZrO 2 When the mass percentage of ZrO is 0%, the mass percentage of CMS mixture is 1.75%, when ZrO 2 When the mass percentage of the CMS mixture is 0.25%, the mass percentage of the CMS mixture is 1.5%, when the ZrO 2 When the mass percent of Al is 0.5%, the mass percent of CMS mixture is 1.25%, as shown in Table 1, corresponding to implementing 1~3 respectively, according to proportioning Al 2 o 3 , Y 2 o 3 , ZrO 2 After mixing with the CMS mixture, add deionized water ball mill for 6 hours and then dry; add polyvinyl a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com