Method for preparing heavy metal chelating agent with waste oil or animal and vegetable oil

A heavy metal chelating agent, animal and vegetable oil technology, applied in the field of environmental chemistry and green chemistry, can solve the problems of slow effect, long cycle, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

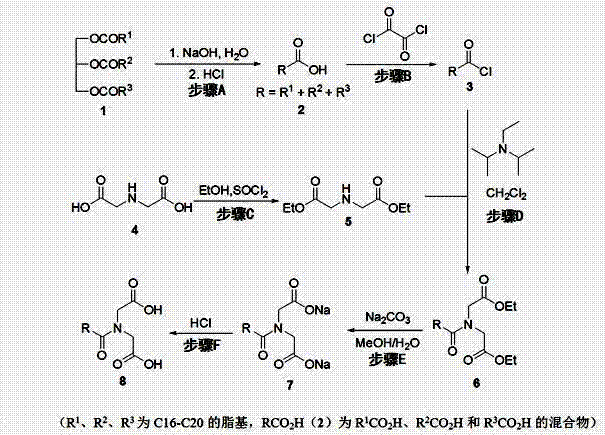

[0016] Example 1: Synthesis of Fatty Acid Mixtures

[0017] Sunflower oil recovered from leftovers (attached figure 1 , structural formula 1, 20 g, about 24 mmol) and sodium hydroxide aqueous solution (15g / 100 mL, 375 mmol) were heated to 70 o C, stirred overnight. Acidify with 6N hydrochloric acid to pH about 2, and extract twice with ethyl acetate (2×40 mL). The combined organic phases were filtered and dried with a magnesium sulfate filter cake, and the fatty acid mixture 2 (19.1 g, about 100% yield) was obtained after vacuum distillation (recovering the organic solvent);

[0018] Appearance: bright yellow oily liquid; R f = 0.38 (20% ethyl acetate / n-hexane); 1 H-NMR (400MHz, CDCl 3 ) δ 11.03 (s, 1H), 5.41-5.30 (m, 2H), 2.29 (t, J = 7.3 Hz, 2H),2.07-1.99 (m, 3H), 1.63-1.56 (m, 2H), 1.42-1.16 (m, 19H), 0.90-0.86 (m, 3H)ppm; 13 C-NMR (100 MHz, CDCl 3 ) δ 180.5, 130.3, 130.1, 129.8, 128.1, 34.8, 32.0,31.6, 29.9, 29.8, 29.7, 29.5, 29.4, 29.3, 27.3, 25.7, 25.0, 22.8, ...

Embodiment 2

[0019] Embodiment 2: the synthesis of aliphatic chain acid halide mixture

[0020] Add oxalyl chloride (2 mL) to fatty acid mixture 2 (2 g, about 7 mmol) in dichloromethane (6 mL) while stirring, stir overnight at room temperature, distill under reduced pressure to remove oxalyl chloride to obtain fat Alkyl acid chloride mixture 3.

Embodiment 3

[0021] Embodiment 3: the synthesis of iminodiacetic acid diester

[0022] at 0 o Slowly add thionyl chloride to the ethanol under stirring, rise to room temperature and continue stirring for about half an hour. Then iminodiacetic acid (formula 4, 3.33 g, 25 mmol) was added, and the temperature was raised to reflux overnight. After cooling to room temperature, the reaction was quenched with saturated sodium bicarbonate solution (20 mL), and then solid sodium bicarbonate was added to adjust the pH to neutral. After most of the ethanol was recovered by distillation under reduced pressure, ethyl acetate was added to extract three times (3×20 mL). The organic phases were combined, washed once with saturated brine, filtered and dried with magnesium sulfate filter cake, and diethyl iminodiacetate was obtained after vacuum distillation (recovering the organic solvent) (Formula 5, 4.15 g, yield 88%) ;

[0023] Characterization: colorless liquid; R f = 0.56 (8% methanol / dichlorom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com