Anti-sulfate competitive adsorption type silane modified polycarboxylate water reducing agent and preparation method thereof

A technology of competitive adsorption and silane modification, which is applied in the field of polycarboxylate superplasticizer and its preparation, can solve the problems of reduced dispersion and retention performance of polycarboxylate superplasticizer, changes in setting time and dispersion retention performance, and concrete slump. The problems such as the increase of time loss can be solved, and the effect of low total porosity, good fluidity and high compactness can be achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

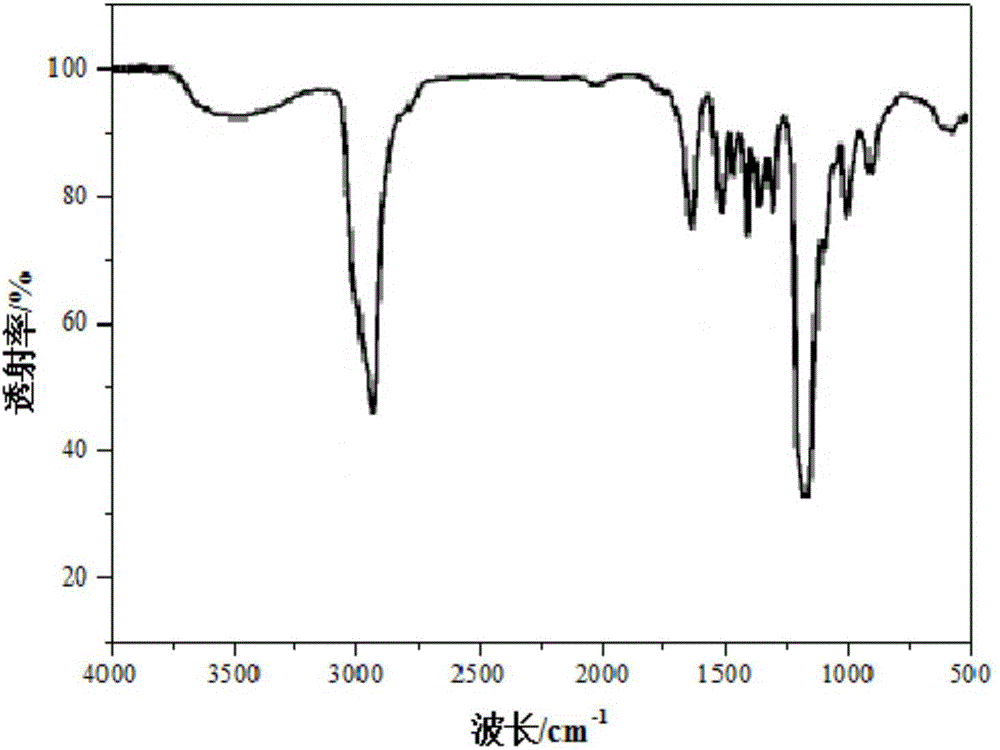

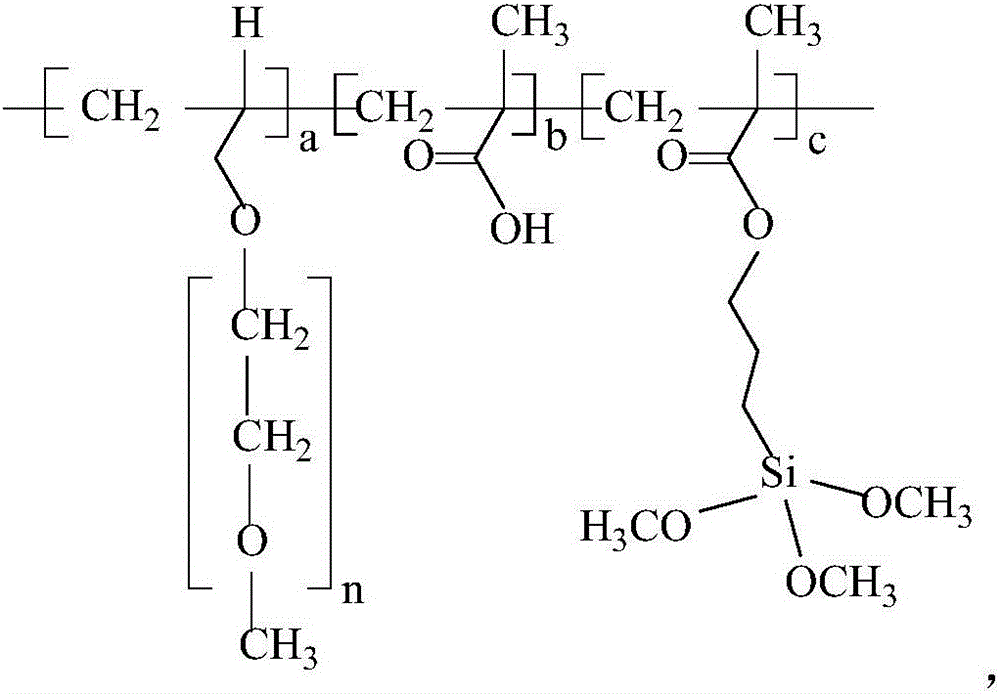

Image

Examples

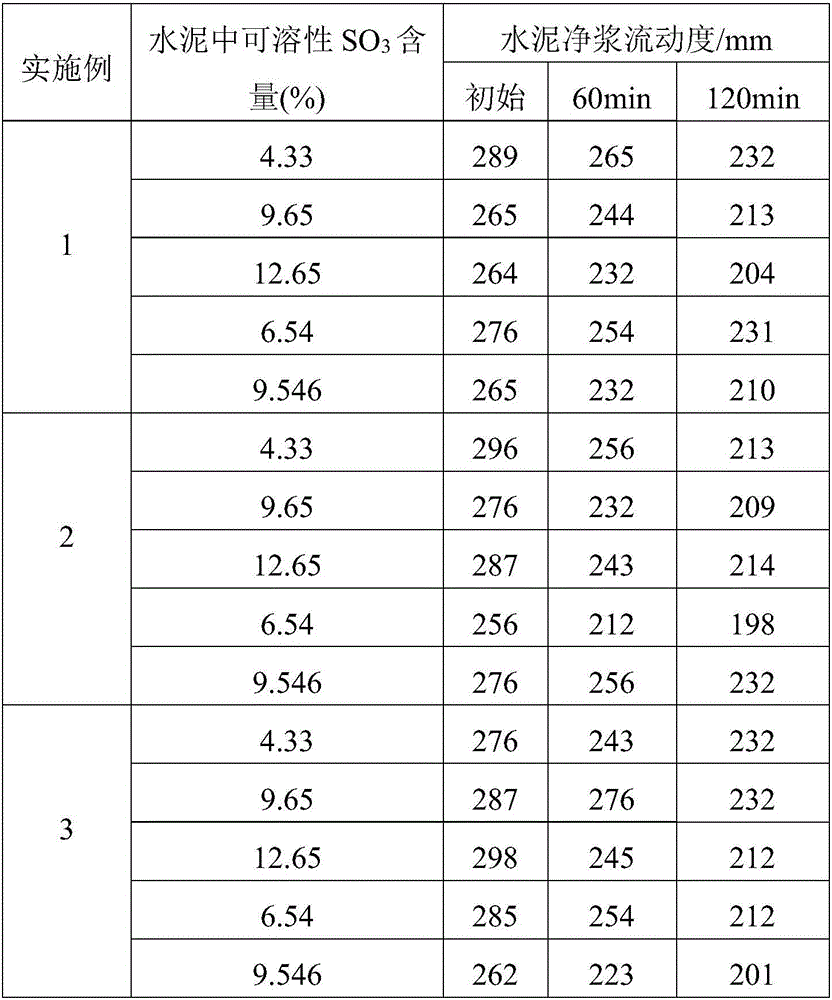

Embodiment 1

[0032] A sulfate-resistant competitive adsorption type silane-modified polycarboxylate water reducer, made of the following components in parts by weight: 100 parts of isobutylene alcohol polyoxyethylene ether, 3 parts of acrylic acid, and 10 parts of γ-methacryloyl Oxypropyltrimethoxysilane, 1.0 parts of ammonium persulfate, 0.4 parts of hydrogen peroxide, 0.5 parts of L-ascorbic acid, 1.0 parts of mercaptopropionic acid, 160 parts of water.

[0033] The concrete preparation method of above-mentioned water reducing agent is as follows:

[0034] Put isobutylene alcohol polyoxyethylene ether and a certain amount of tap water into the reaction container, and use a stirring device to dissolve all the raw materials; put ammonium persulfate, hydrogen peroxide, γ-methacryloxypropyltrimethoxysilane, etc. into the above reaction at one time Container, using a stirrer to mix the system evenly; heat the reaction system and control the system temperature to be constant at 70°C, and at th...

Embodiment 2

[0037] A sulfate-resistant competitive adsorption type silane-modified polycarboxylate water reducer, made of the following components in parts by weight: 100 parts of isobutylene alcohol polyoxyethylene ether, 5 parts of acrylic acid, and 4 parts of γ-methacryloyl Oxypropyltrimethoxysilane, 0.5 parts of ammonium persulfate, 0.4 parts of hydrogen peroxide, 0.4 parts of L-ascorbic acid, 0.6 parts of mercaptopropionic acid, 130 parts of water.

[0038] The concrete preparation method of above-mentioned water reducing agent is as follows:

[0039] Put isobutylene alcohol polyoxyethylene ether and a certain amount of tap water into the reaction container, and use a stirring device to dissolve all the raw materials; put ammonium persulfate, hydrogen peroxide, γ-methacryloxypropyltrimethoxysilane, etc. into the above reaction at one time container, using a stirrer to mix the system evenly; heat the reaction system and control the temperature of the system to be constant at 60°C, and s...

Embodiment 3

[0041] A sulfate-resistant competitive adsorption type silane-modified polycarboxylate water reducer, made of the following components in parts by weight: 100 parts of isobutylene alcohol polyoxyethylene ether, 4 parts of acrylic acid, and 6 parts of γ-methacryloyl Oxypropyltrimethoxysilane, 0.7 parts of ammonium persulfate, 0.6 parts of hydrogen peroxide, 0.4 parts of L-ascorbic acid, 1.0 parts of mercaptopropionic acid, 160 parts of water.

[0042] The concrete preparation method of above-mentioned water reducing agent is as follows:

[0043] Put isobutylene alcohol polyoxyethylene ether and a certain amount of tap water into the reaction container, and use a stirring device to dissolve all the raw materials; put ammonium persulfate, hydrogen peroxide, γ-methacryloxypropyltrimethoxysilane, etc. into the above reaction at one time container, use a stirrer to mix the system evenly; heat the reaction system and control the temperature of the system to be constant at 50°C, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com