Poly-rhodanine coated inorganic packing as well as preparation method and application thereof

A technology of inorganic nano-filler and coating, applied in the field of reinforced rubber, can solve the problems of large influence of vulcanization characteristics, low promotion efficiency, slow vulcanization rate, etc., to improve dispersion, improve interfacial adhesion, and reduce dependence. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

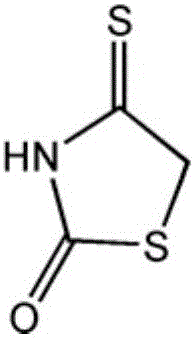

[0035] (1) Coating modified white carbon black with polyrhodanine as the inorganic filler reinforced by styrene-butadiene rubber, the specific preparation process is as follows: the white carbon black is dispersed in water to obtain a concentration of 5wt% water dispersion; the rhodanine ( The mass ratio of white carbon black to rhodanine is 10 / 1) added to the above water dispersion, stirred at 80°C for 5 minutes; adding ammonium persulfate oxidant to the above water dispersion, reacted at 80°C for 1 hour, and filtered Polyrhodenin-coated silica is available. The specific coating amount of polyrhodanine in the modified filler is 3%. From the infrared results, it can be explained that in the modified filler, the 1680cm -1 and 1480cm -1 Two new absorption peaks appeared, representing the vibrational absorption peaks of C=C and C-N respectively, which also corresponded to the characteristic absorption peaks of polyrhodenine, which proved the successful coating of polyrhodanine ...

Embodiment 2

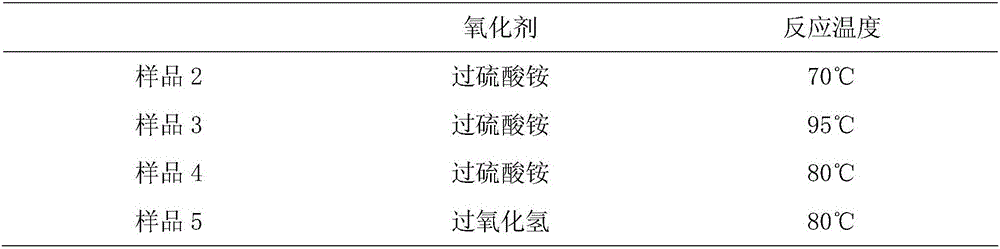

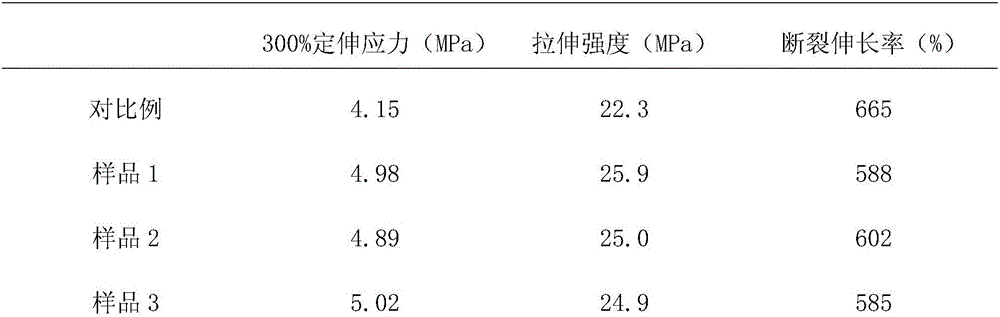

[0038] (1) To study the effect of polyrhodenine coating process on silica reinforced rubber composites. The specific implementation process is as follows: disperse white carbon black in water to obtain a water dispersion with a concentration of 5wt%; add rhodanine (the mass ratio of white carbon black and rhodanine is 10 / 1) to the above-mentioned water dispersion, Stir at high temperature for 5min (the specific implementation temperature is as shown in Table 1); add the oxidizing agent to the above-mentioned water dispersion (the specific oxidizing agent used is as shown in Table 1), stir at the reaction temperature for 1h, and after filtration, you can obtain the polymerization under different polymerization process conditions. Silica coated with rhodanine. From the infrared results, it can be explained that in the modified filler, the 1680cm -1 and 1480cm -1 Two new absorption peaks appeared, representing the vibrational absorption peaks of C=C and C-N respectively, which ...

Embodiment 3

[0044](1) using halloysite as the inorganic filler reinforced by styrene-butadiene rubber, the specific preparation process is as follows: halloysite is dispersed in water to obtain a concentration of 10wt% aqueous dispersion; Mass ratio = 15 / 1) added to the above water dispersion, stirred at 80°C for 5 minutes; added ammonium persulfate oxidant to the above water dispersion, reacted at 80°C for 1 hour, and filtered to obtain polyrhodanine coating Modified Halloysite. From the infrared results, it can be explained that in the modified filler, the 1680cm -1 and 1480cm -1 Two new absorption peaks appeared, representing the vibrational absorption peaks of C=C and C-N respectively, which also corresponded to the characteristic absorption peaks of polyrhodenine, which proved the successful coating of polyrhodanine on the surface of silica. The specific coating amount of polyrhodanine is obtained by thermogravimetric analysis. After the temperature is raised to 700°C during the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com