Preparation method and application of composite wave absorbing material of graphene and zeolite

A composite absorbing material, graphene technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of difficult to achieve large-scale production, poor absorbing performance, high density, etc., to achieve low material cost, coverage The effect of a wide range and simple experimental equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

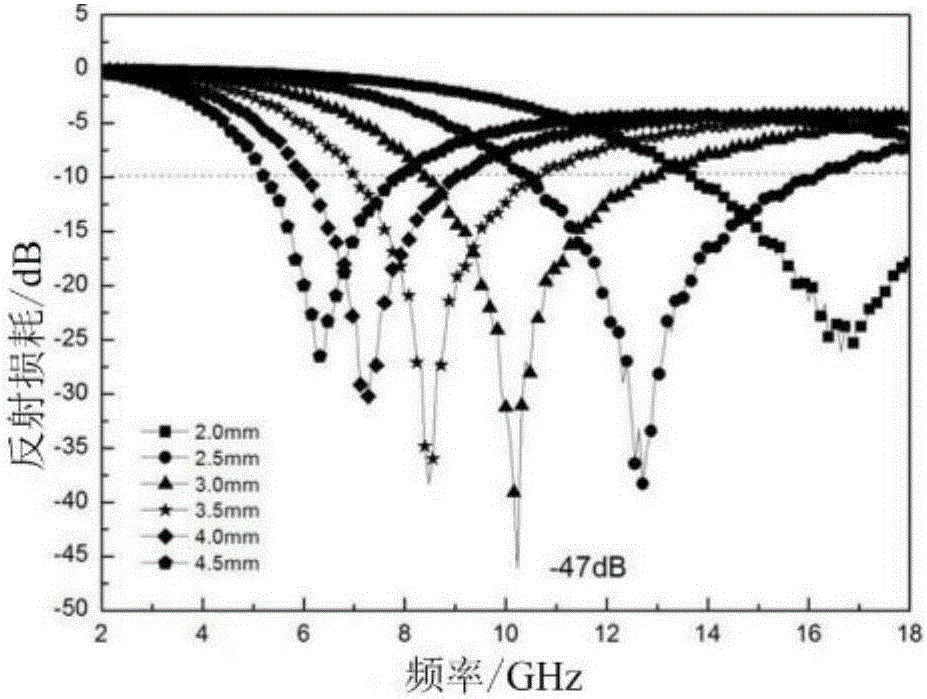

Embodiment 1

[0056] (1) Graphene is prepared by chemical redox method.

[0057] Ⅰ. Dissolve graphite oxide in an ethanol solution with a volume ratio of ethanol and water of 1:1, and sonicate for 10-15 minutes to obtain a 1 mg / ml graphite oxide solution.

[0058] II. Transfer 80ml of the above solution into a reaction kettle, add 10mg of sodium borohydride, place the reaction kettle in an oven at 120°C for 4 hours, and cool down to room temperature naturally.

[0059] III. The product was taken out from the reaction kettle, washed three times with deionized water, and then dried in an oven at 45°C to obtain chemically reduced graphene oxide.

[0060] (2) Preparation of graphene graphene and zeolite composite absorbing material.

[0061] a. Dissolve 0.1807g of NaOH solution in 40ml of deionized water, divide it into NaOH solution, divide it into two parts, add 2.0625g of sodium metaaluminate to one of the NaOH solutions, stir until the solution is clear, then add 0.0090g of step (1 ) in G...

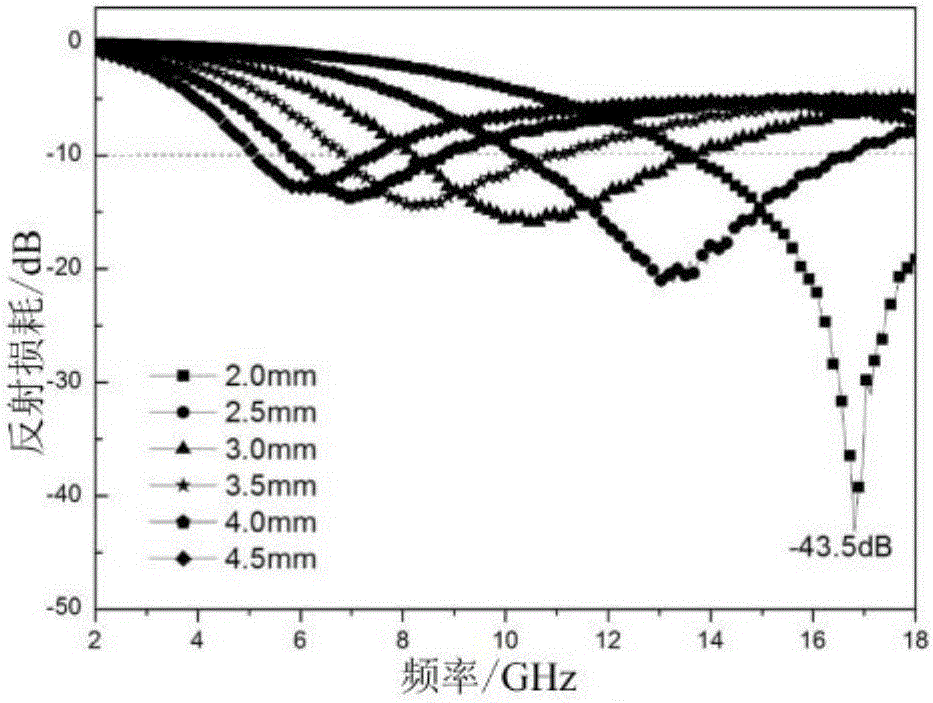

Embodiment 2

[0070] (1) Graphene was prepared by microwave redox method.

[0071] 1. Dissolve graphite oxide in an ethanol solution with a volume ratio of ethanol and water of 1:1, and sonicate for 10-15 minutes to obtain a 1 mg / ml graphite oxide solution.

[0072] II. Divide 80mL of the above solution into 4 digestion tubes, put it into a microwave digestion apparatus, raise the temperature to 120°C under the condition of 800W, and react for 10min to obtain the reduced graphene oxide solution after microwave treatment.

[0073] (2) Preparation of graphene graphene and zeolite composite absorbing material.

[0074] a. Dissolve 0.1807g of NaOH solution in 40ml of deionized water, divide it into NaOH solution, divide it into two parts, add 2.0625g of sodium metaaluminate to one of the NaOH solutions, stir until the solution is clear, then add 0.0090g of step (1 ) using the graphene prepared by the microwave redox method, ultrasonically dispersed for 8min to obtain solution A;

[0075] b. A...

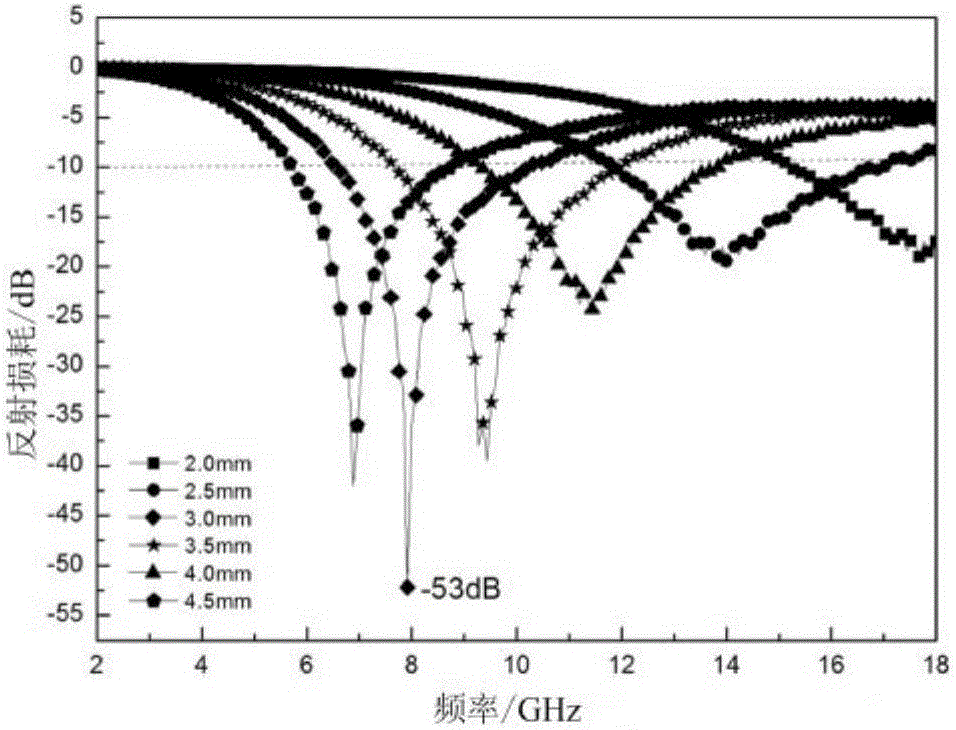

Embodiment 3

[0083] (1) Graphene is prepared by thermal expansion method.

[0084] Grind graphite oxide into powder, put it into a tube furnace, seal the heating nozzle, gradually raise the temperature to 200°C, and keep it for 4 hours, then cool down to obtain thermally expandable graphene.

[0085] (2) Preparation of graphene graphene and zeolite composite absorbing material.

[0086] a. Dissolve 0.1807g of NaOH solution in 40ml of deionized water, divide it into NaOH solution, divide it into two parts, add 2.0625g of sodium metaaluminate to one of the NaOH solutions, stir until the solution is clear, then add 0.0090g of step (1 ) in Graphene prepared by thermal expansion method, ultrasonic dispersion 8min, to obtain solution A;

[0087] b. Add 3.87g sodium metasilicate to another part of NaOH solution, stir until the solution is clear, then add 0.0090g of graphene prepared by thermal expansion method in step (1), and ultrasonically disperse for 8min to obtain solution B;

[0088] c. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com