Method for rapidly and efficiently brewing red rice mature vinegar

A high-efficiency technology of red koji mature vinegar, which is applied in the field of rapid and efficient brewing of red koji mature vinegar, can solve the problems of low saccharification koji or glucoamylase activity, low vinegar production rate, and affecting the production rate of mature vinegar, so as to improve productivity and improve production efficiency , the effect of shortening the brewing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0020] A method for rapidly and efficiently brewing red yeast rice vinegar, comprising the following steps in sequence:

[0021] 1) Select 100 parts by mass of glutinous rice without mildew and impurities, wash and soak at room temperature for 4 to 10 hours;

[0022] 2) After fully soaking, use a sander to refine the pulp until there are no obvious particles. The concentration of the slurry is controlled at 18-20 Baume and poured into the pulp cooking tank for cooking. After cooking, add α-amylase and liquefy at 90-93°C for 30-60 minutes. , 100°C to inactivate the enzyme;

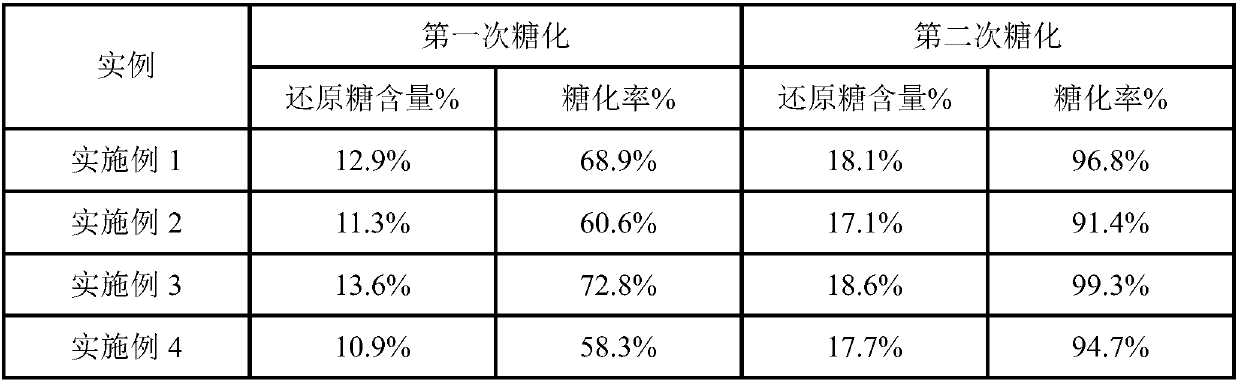

[0023] 3) Cool to 60-65°C, add 0.5-1 parts by mass of glucoamylase, and saccharify for the first time for 1.5-2 hours. The glucoamylase is compounded by Pullulan and glucoamylase according to the mass ratio of 2:1. become;

[0024] 4) After the first saccharification, add 0.5-1 parts by mass of Monascus bran koji, and saccharify the second time for 1-1.5 hours;

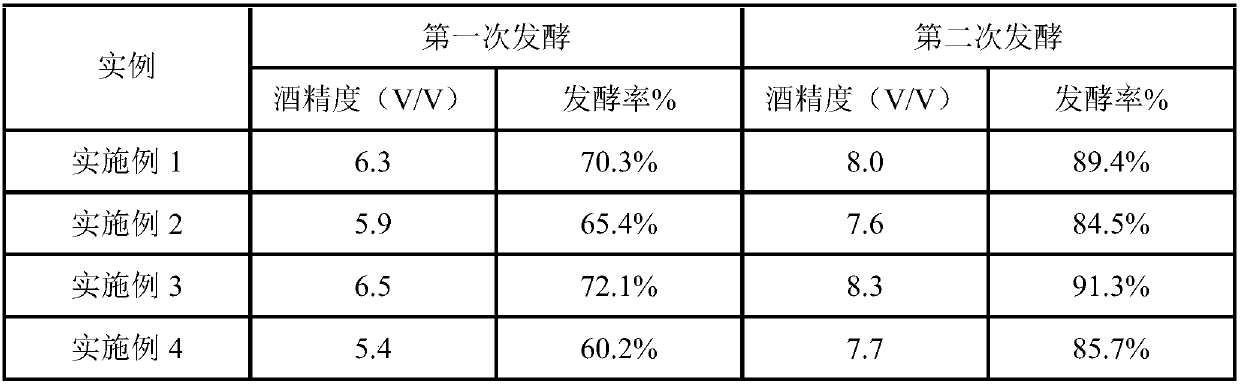

[0025] 5) Primary alcohol fermentation: a...

Embodiment 1

[0032] A method for rapidly and efficiently brewing red yeast rice vinegar, the steps are as follows:

[0033] 1) Select 100 parts by mass of glutinous rice without mildew and impurities, soak at room temperature for 8 hours after cleaning;

[0034] 2) After fully soaking, use a sander to refine the pulp until there are no obvious particles. The concentration of the slurry is controlled at 18-20 Baume and poured into a pulp cooking tank for cooking. After cooking, add α-amylase to liquefy at 90-93°C for 40 minutes. ℃ inactivate enzyme;

[0035] 3) Cool to 60-65°C, add 1 part by mass of glucoamylase, and saccharify for the first time for 2 hours. The glucoamylase is compounded by pullulan mold and glucoamylase in a mass ratio of 2:1;

[0036] 4) After the first saccharification, add 0.6 parts by mass of Monascus bran koji, and make the second saccharification for 1.5 hours;

[0037] 5) Primary alcohol fermentation: after the second saccharification, control the inoculation te...

Embodiment 2

[0042] A method for rapidly and efficiently brewing red yeast rice vinegar, the steps are as follows:

[0043] 1) Select 100 parts by mass of glutinous rice without mildew and impurities, soak at room temperature for 10 hours after cleaning;

[0044] 2) After fully soaking, use a sander to refine the pulp until there are no obvious particles. The concentration of the slurry is controlled at 18-20 Baume and poured into a pulp cooking tank for cooking. After cooking, add α-amylase to liquefy at 90-93°C for 40 minutes. ℃ inactivate enzyme;

[0045] 3) Cool to 60-65°C, add 0.8 parts by mass of glucoamylase, and saccharify for 1.5 hours for the first time. The glucoamylase is compounded by pullulan mold and glucoamylase in a mass ratio of 2:1;

[0046] 4) After the first saccharification, add 0.6 parts by mass of Monascus bran koji, and make the second saccharification for 1.5 hours;

[0047] 5) Primary alcohol fermentation: after the second saccharification, control the inoculat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com