Toxic product tolerating cell immobilized method and production process of 1,5-diaminopentane by immobilized cell

A technology for immobilizing cells and cells, applied in the field of microorganisms, can solve the problems of the large impact on the mechanical strength of the immobilized pellets and the inability to meet industrial production, and achieve the effects of easy scale-up of production, product clarification, and less equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

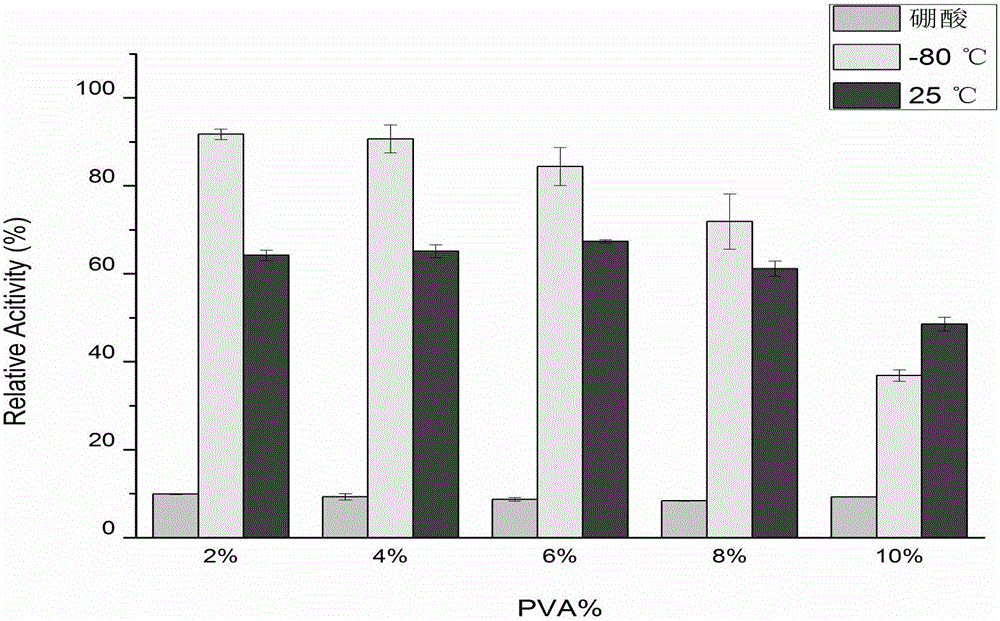

[0033] Mixtures of different concentrations of PVA and 2% sodium alginate were used as immobilized materials, and immobilized cells were prepared by boric acid cross-linking method and freezing method, respectively. The specific operation method is: add polyvinyl alcohol into cold water, heat to 98°C to dissolve, add sodium alginate, heat to dissolve in a sterilizer, stir and cool to 40-50°C, add bacterial suspension to a final concentration of 10g (湿菌重) / L, stir well. Add the above mixed liquid into the cross-linking agent solution dropwise with a syringe or a peristaltic pump to obtain small balls with a diameter of 0.3-0.5 cm. The cross-linking agent of the boric acid cross-linking method uses a saturated boric acid solution containing 3% (mass percentage) calcium chloride; the freezing method cross-linking agent is a 3% (mass percentage) calcium chloride solution. For the pellets prepared by the boric acid cross-linking method, after standing at room temperature for 8 hou...

Embodiment 2

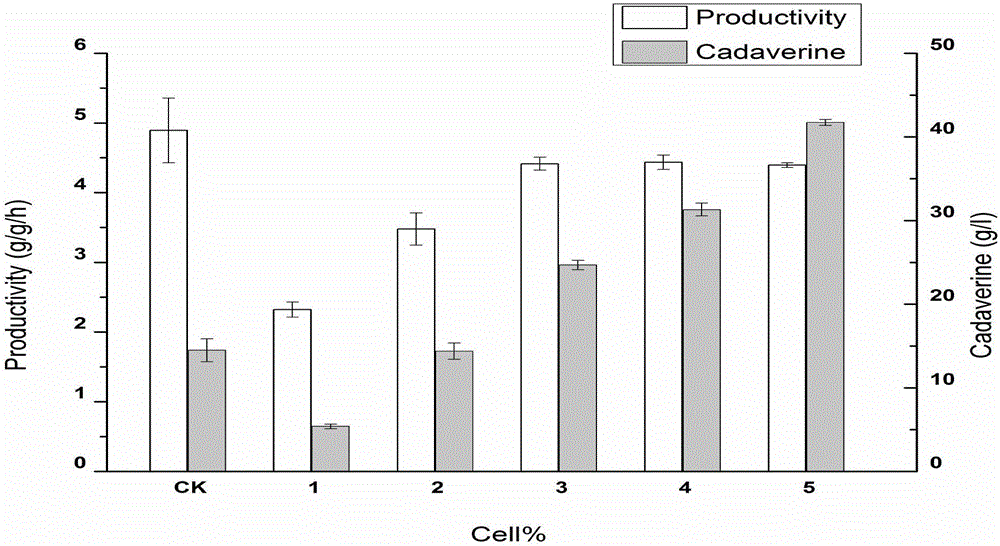

[0039] Immobilized cells were prepared by the freezing method in Example 1, wherein the mass fraction of sodium alginate was 2.0%, the mass fraction of polyvinyl alcohol was 2.0%, and the mass-volume ratio (g / 100mL) of the bacterial cell to the gel solution was 1-5. The relative activity of the immobilized pellets, except for the amount of bacteria in the transformation conditions, the other conditions are the same as in Example 1. The result is as figure 2 As shown, the concentration of 1,5-pentanediamine in the transformation solution increases with the increase of bacterial load, but the yield of 1,5-pentanediamine per unit mass of bacteria does not increase significantly when the bacterial load is greater than 3%. , and when the bacterial load was 3%, the 1,5-pentanediamine yield per unit mass of the immobilized cells was 4.41±0.09g / g (湿菌重) / h, compared with the control (4.89±0.46g / g (湿菌重) / h) compared with no significant difference, indicating that 3% of the bacteria l...

Embodiment 3

[0041] The immobilized cells were prepared by the freezing method in Example 1, and the mass fraction of the immobilized carrier sodium alginate (SA), polyvinyl alcohol (PVA), and the forming agent were tested by the central composite design (CCD) test in the response surface method analysis method. Factors such as mass fraction of calcium chloride solution (CaCl2), calcification time and freezing time are optimized. The levels of each factor are shown in Table 1, a total of 32 groups of tests, the conversion reaction conditions are the same as in Example 1. The test results are shown in Table 2. The test results were modeled and analyzed to obtain the regression equation:

[0042] Log10 (loudness vitality) = +1.38-1.81*SA+2.21E-003*PVA-0.26*CaCl 2 +0.039*calcification time-0.028*freezing time+0.074*SA*PVA+0.32*SA*CaCl 2 +0.053*SA*freezing time+0.27*SA 2 -0.014*PVA 2 -0.036*CaCl 2 2 -1.64E-003*calcification time 2 -1.94E-003*freezing time 2 -0.01*SA 2 *PVA-0.046*SA ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com